Magnetic suspension track inspection railcar

A technology of maglev track and inspection vehicle, which is applied to railway inspection vehicles and other directions, and can solve problems such as inappropriateness and inability to drive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

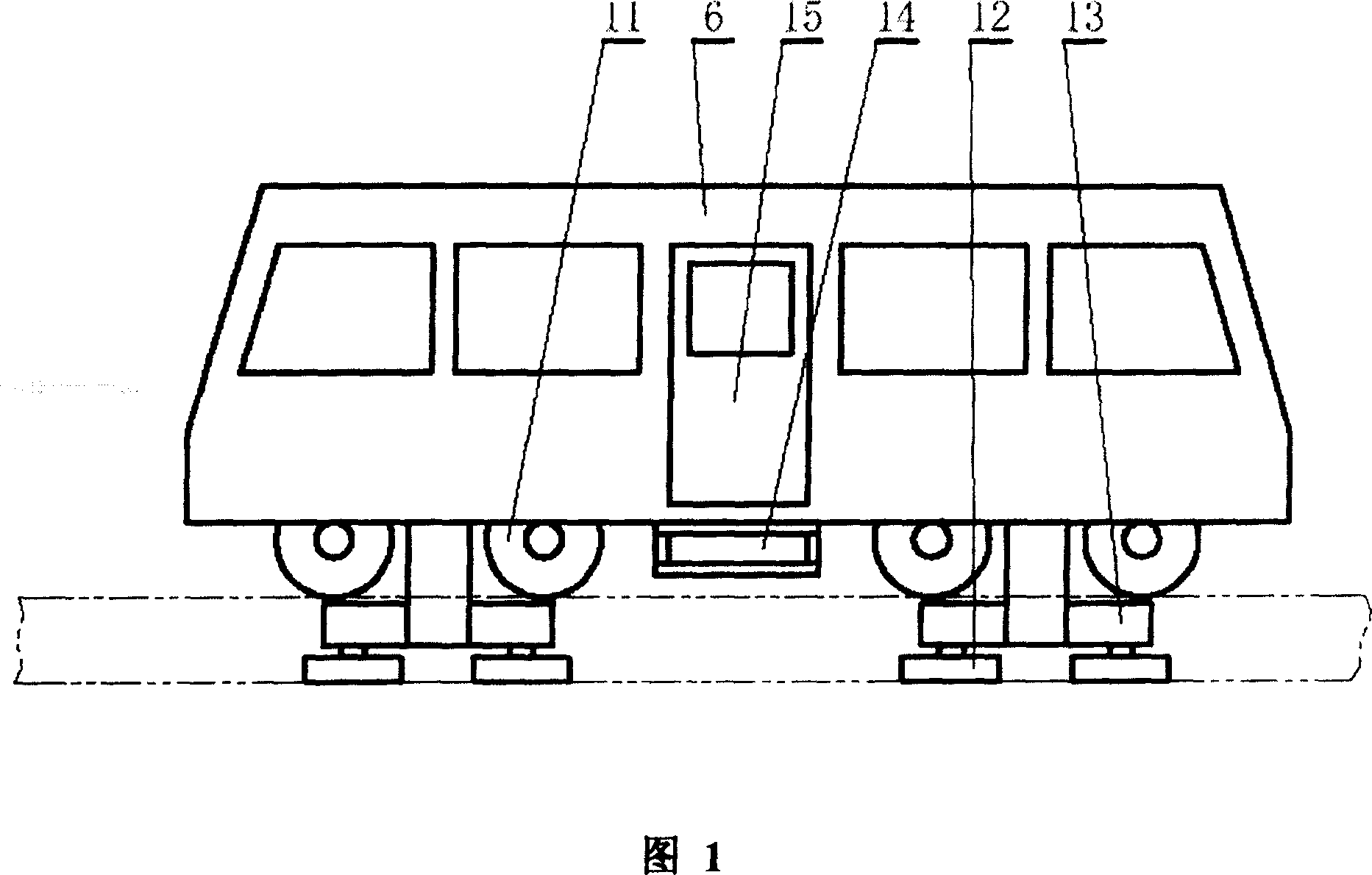

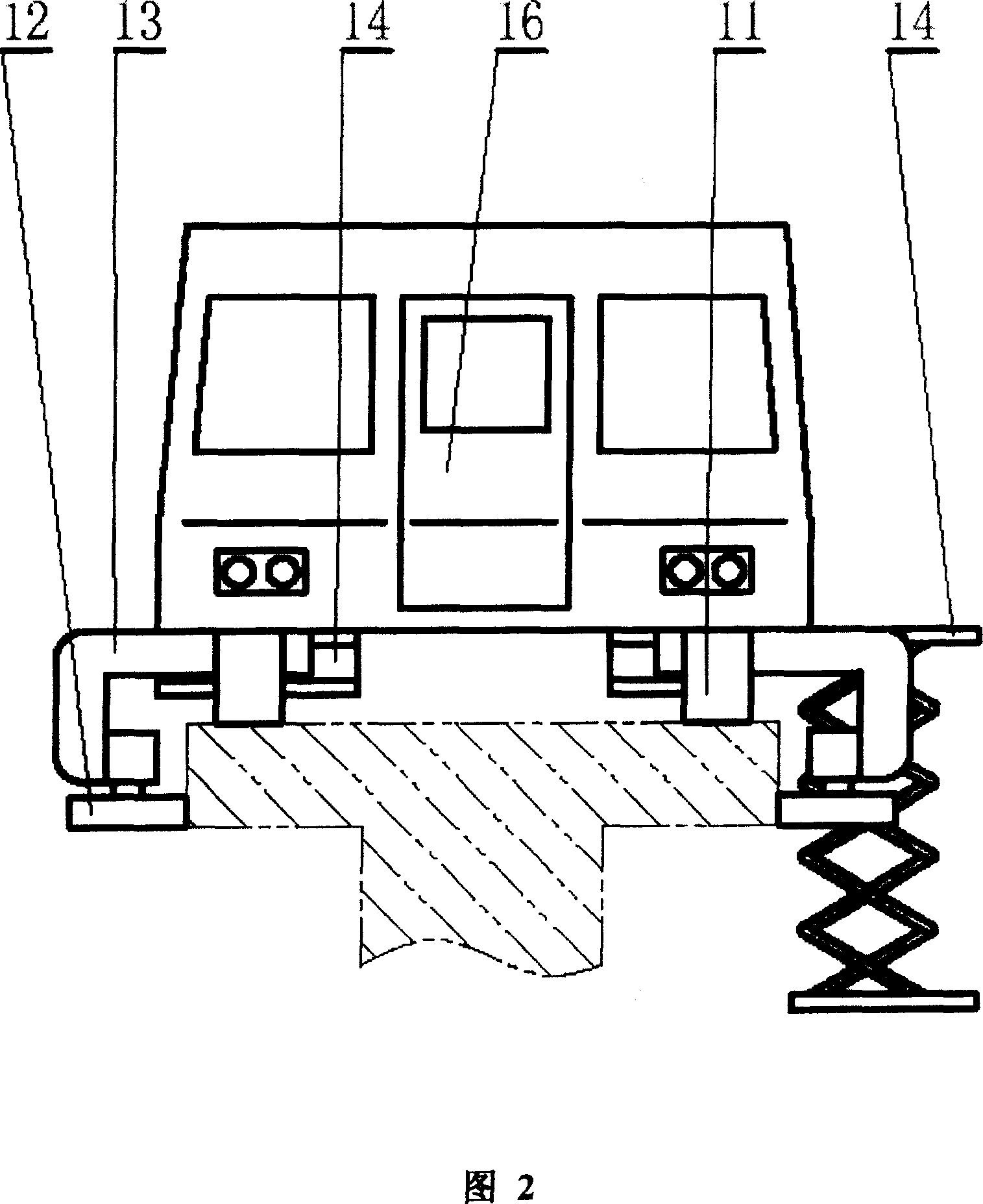

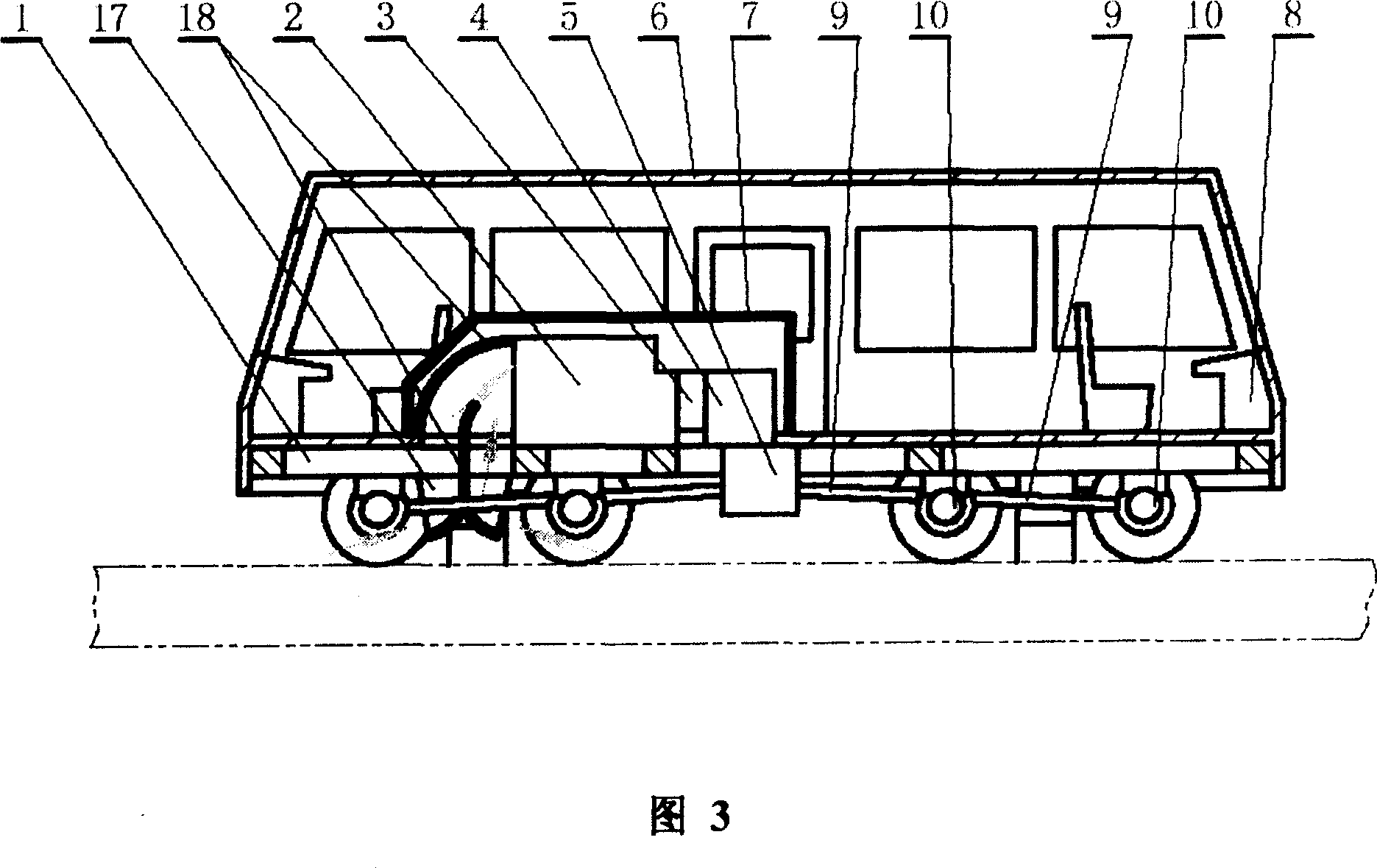

[0013] As shown in Fig. 1, Fig. 2 and Fig. 3, the present invention includes: vehicle frame 1, engine 2, hydraulic torque converter 3, gearbox 4, inter-axle differential 5, vehicle body 6, engine cover 7, instrument console 8. Universal joint 9, drive axle 10, rubber tire wheel 11, lateral guide wheel 12, guide wheel frame 13, maintenance elevator 14. The connection method is: the engine 2 and the gearbox 4 are fixed in the body 6 on the frame 1, the torque converter 3 is connected to the output end of the engine 2, and the gearbox 4 is connected to the output end of the torque converter 3 , the inter-axle differential 5 is connected to the output end of the gearbox 4, and the two output ends of the inter-axle differential 5 are respectively connected to two through joints arranged in the middle under the frame 1 and the body 6 through universal joints 9 Type driving axle 10, these two through-type driving axles 10 are respectively connected through two universal joints 9 to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com