Rope transmission mechanism

A technology of rope transmission and sheave, which is applied in the direction of transmission devices, mechanical equipment, belts/chains/gears, etc., which can solve the problems of inaccurate transmission ratio, high noise, and high cost of the chain, and achieve simple structure and adaptability of the sheave Wide, easy installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

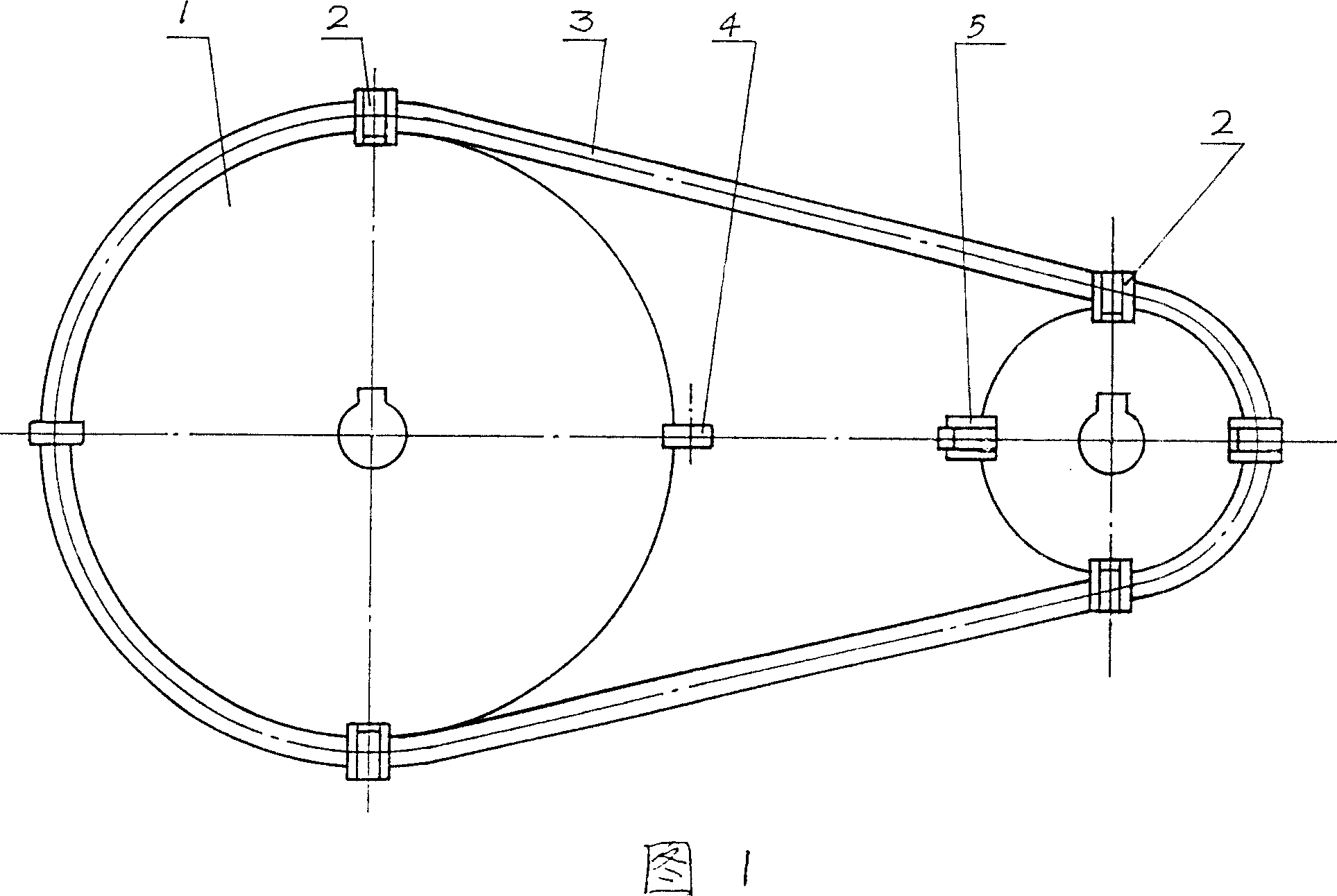

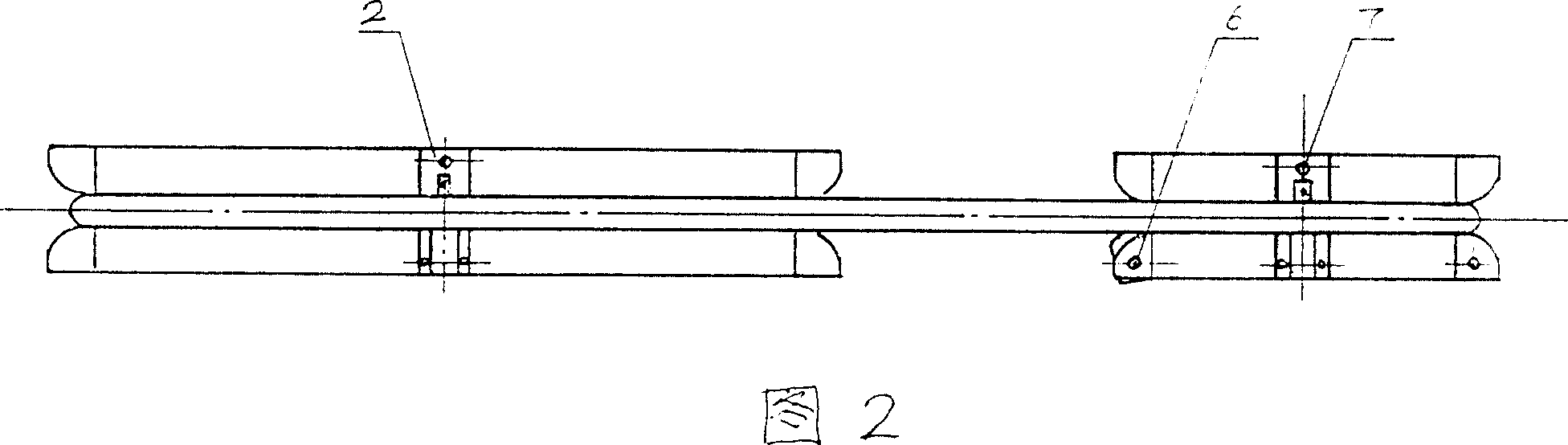

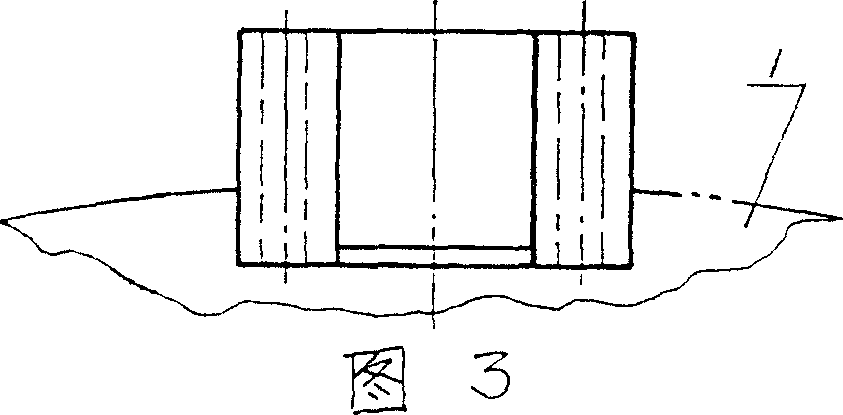

[0033] With reference to Fig. 1 to Fig. 19, on the outer edge of rope wheel 1, there is not buckle 2, plate stumble 4 that are fixed with wheel 1, and the rope 3 that forms loop is tensioned and sheathed on two wheels 1. Buckle 5 is the buckle (compared with Fig. 6 or Fig. 15) when the rope is not fastened, and buckle 2 is fixedly installed by fastening bolt 7 and wheel 1. The buckle bolt 9 is looped on the buckle shaft 6, and is inserted into the buckle frame 8 alive. The rope 3 is fastened by fastening points 11 (there are two fastening points 11 on Fig. 4, so it is called multi-point buckle; there is one fastening point 11 on Fig. Between 8, be formed with rope notch 12, also have corresponding rope notch 12 on flat board trip 4 and many pile trips 14.

[0034] When the buckle 2 is in the buckle 5 state, the front end of the buckle 9 is lifted under the push of the elastic element 10 (see Figure 6), and the notch 12 is opened to a state where the rope 3 is easy to enter. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com