Catalyst for producing synthesis gas or hydrogen and its production method and application

A catalyst and synthesis gas technology, which is applied to catalysts and their preparation methods and application fields, can solve problems such as poor stability and easy deactivation, and achieve the effects of good temperature resistance, good thermal stability and wide operating temperature range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

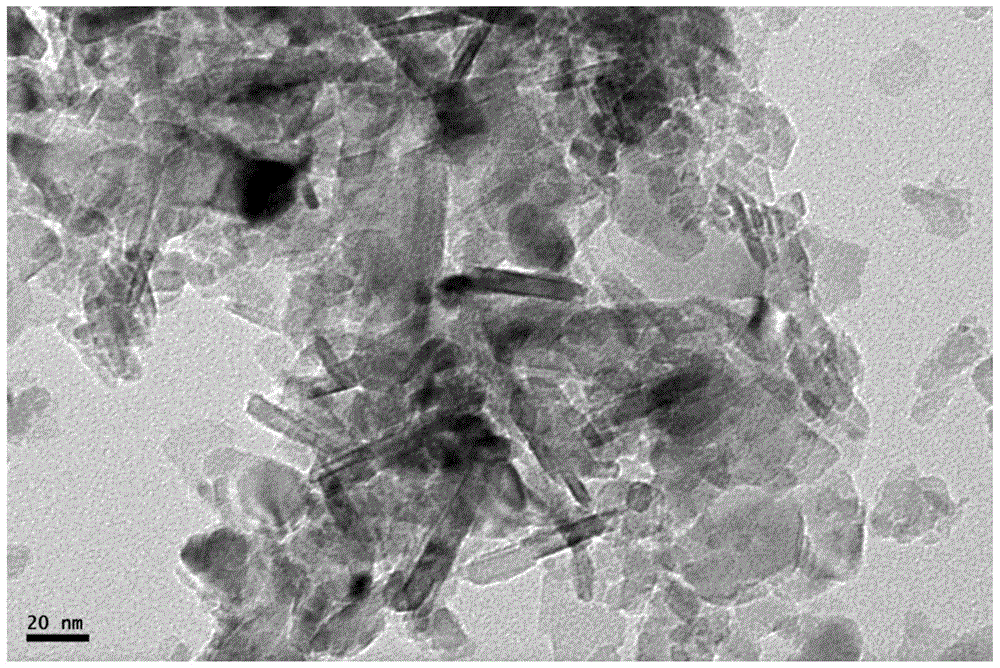

Image

Examples

Embodiment 1

[0068] 0.02mol of Ni(NO 3 ) 2 ·6H 2 O, 0.005mol of Cr(NO 3 ) 3 9H 2 O, 0.04mol of Mg(NO 3 ) 2 ·6H 2 O, 0.005mol La(NO 3 ) 3 ·6H 2 O and 0.015mol of Al(NO 3 ) 3 9H 2 O was dissolved in 100ml of deionized water, which was called solution A.

[0069] 0.16mol of NaOH and 0.01mol of Na 2 CO 3 Dissolve in 100ml of deionized water and set as solution B.

[0070] Then, solution A and solution B were transferred to two separatory funnels respectively for subsequent use, solution A was added dropwise in a 500ml beaker with 100ml deionized water at a flow rate of 2ml / min, and solution B was added dropwise at the same time, and The pH of the precipitation environment was controlled to be 10 by adjusting the dropping speed, and the mixture was continuously stirred (the stirring speed was 500 rpm). After the dropwise addition was completed, the stirring was continued for 3 hours, and then aged at 60° C. for 24 hours. Wash with 2000ml deionized water and filter with suction ...

Embodiment 2

[0073] 0.005mol of Cr 2 o 3 , 0.01mol of light MgO, 0.04mol of γ-Al 2 o 3 Mix and grind with a mortar, dissolve 0.01mol of nickel acetate in 20ml of deionized water, then pour it into the above-mentioned mixed and ground material, and continue to mix and grind for 2 hours. After that, let it stand for 12 hours, and then dry it at 80°C for 12 hours. After pre-calcining at 400°C for 2 hours, calcining at 1000°C in an air atmosphere for 4 hours, the catalyst Cr-Ni-Mg-Al composite oxide was obtained. The catalyst was crushed through a 100-mesh sieve, then pressed into tablets, crushed with a crushing sieve, and sieved into 80-100 mesh Reserved.

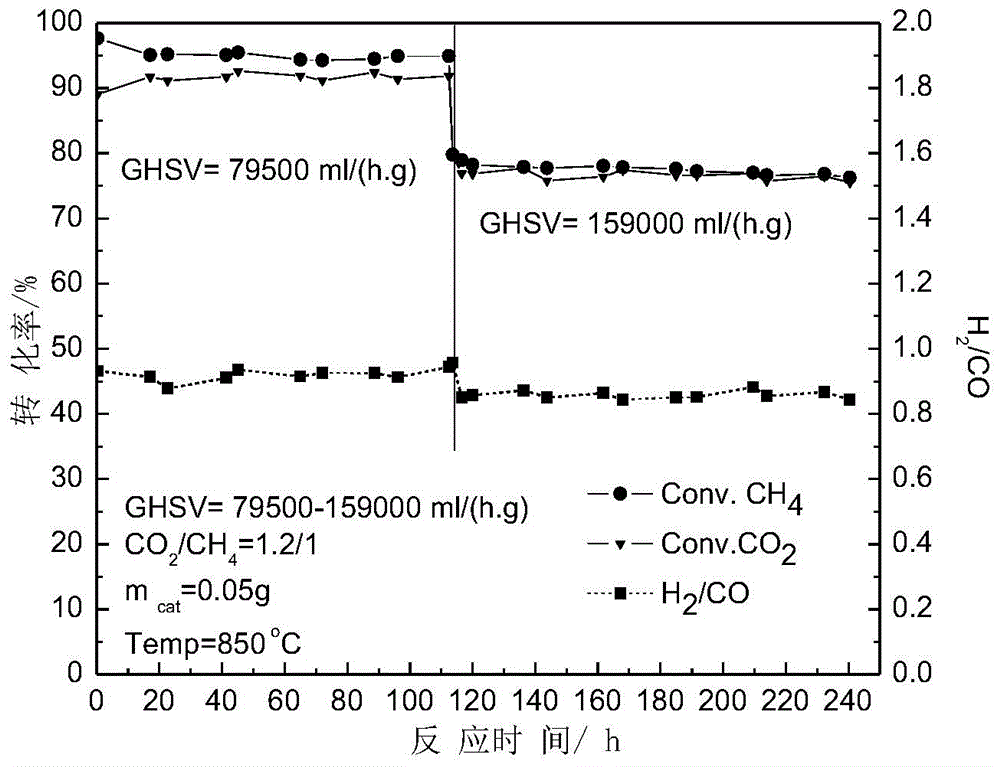

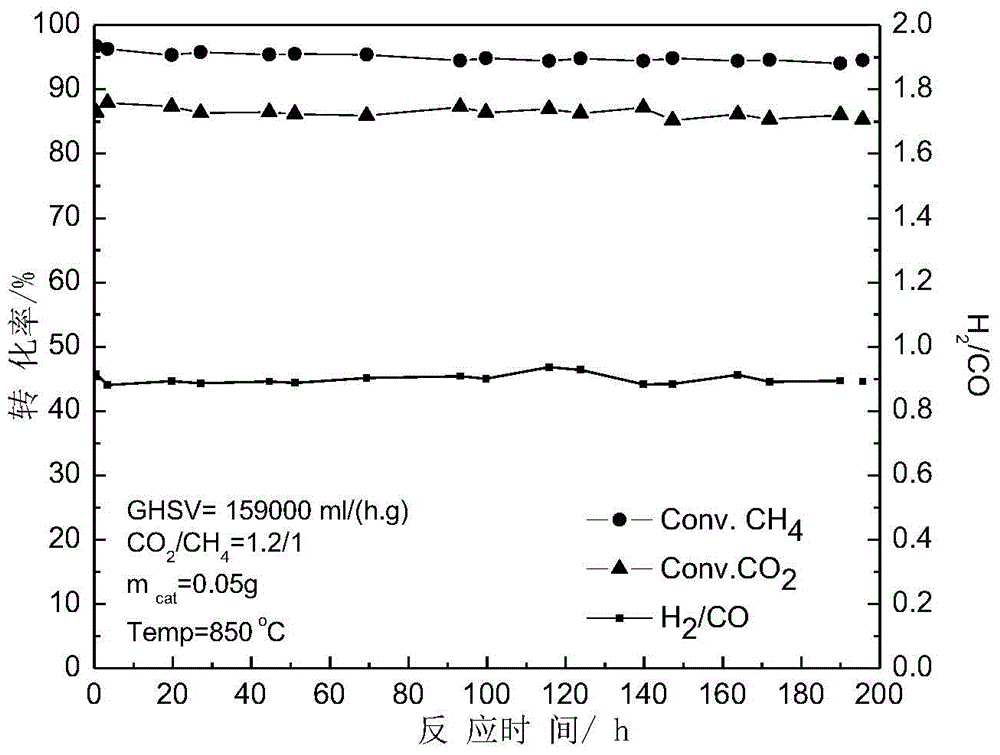

[0074] Get 0.05 grams of catalyst, mix it with 1.0 g of quartz sand of the same mesh number (80-100 mesh), put it into a quartz tube reactor with an inner diameter of 10.0 mm, and use H 2 / N 2 is 1 / 1, the temperature is programmed to rise to the reaction temperature of 850°C, and the dry reforming reaction of methane is carried out,...

Embodiment 3

[0076] Select 100g γ-Al 2 o 3 As a carrier, the carrier is crushed and passed through a 100-mesh sieve for subsequent use; 0.001mol of lanthanum nitrate is dissolved in 10ml of distilled aqueous solution, marked as solution A, for subsequent use; 0.01mol of Ni(NO 3 ) 2 ·6H 2 O, 0.005mol of Cr(NO 3 ) 3 9H 2 O was dissolved in 40ml of distilled aqueous solution, marked as solution B, and set aside.

[0077] Immerse solution A in the above sieved γ-Al 2 o 3 As a carrier, stir for 2 hours, age for 24 hours, and dry at 80°C for 6 hours. After pre-calcining at 400°C for 2 hours, calcining at 800°C in an air atmosphere for 4 hours to obtain La surface-modified γ-Al 2 o 3 Carrier (i.e. La / γ-Al 2 o 3 carrier), and then impregnated solution B in the modified La / γ-Al 2 o 3 on the carrier, stirred for 2 hours, aged for 24 hours, and dried at 80°C for 6 hours. After pre-calcining at 400°C for 2h, calcining in air atmosphere at 800°C for 4h, the catalyst Ni-Cr-La / γ-Al was obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com