Fibrosis of tobacco material

A tobacco and fibrillation technology, which is applied in the field of manufacturing tobacco products, can solve the problems of high equipment cost, inappropriateness, and high energy consumption, and achieve the effects of low cost, less fines, and shortened storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

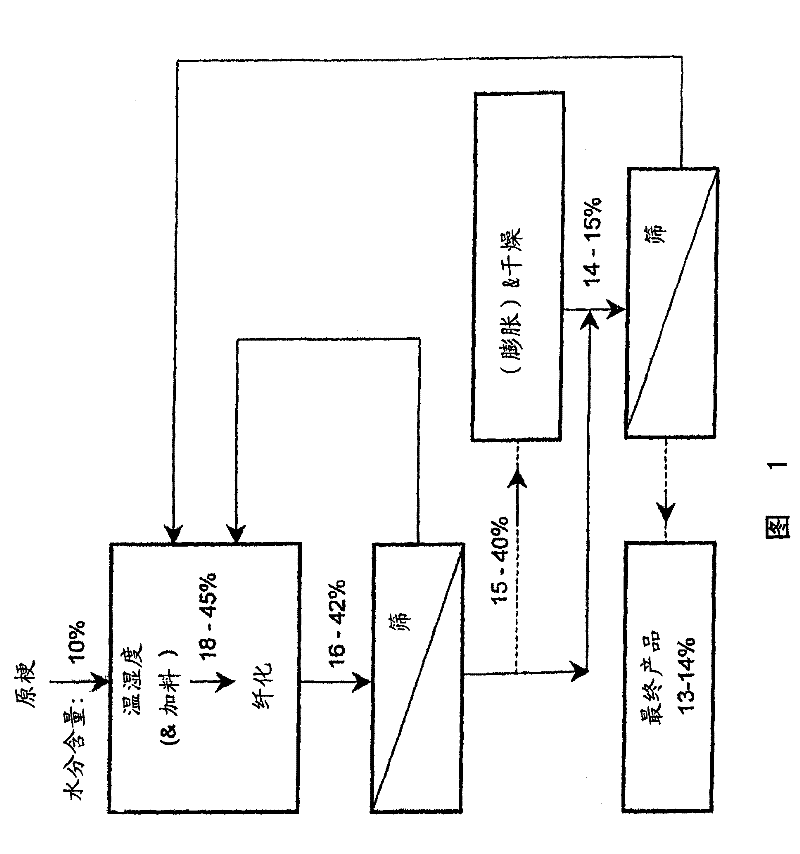

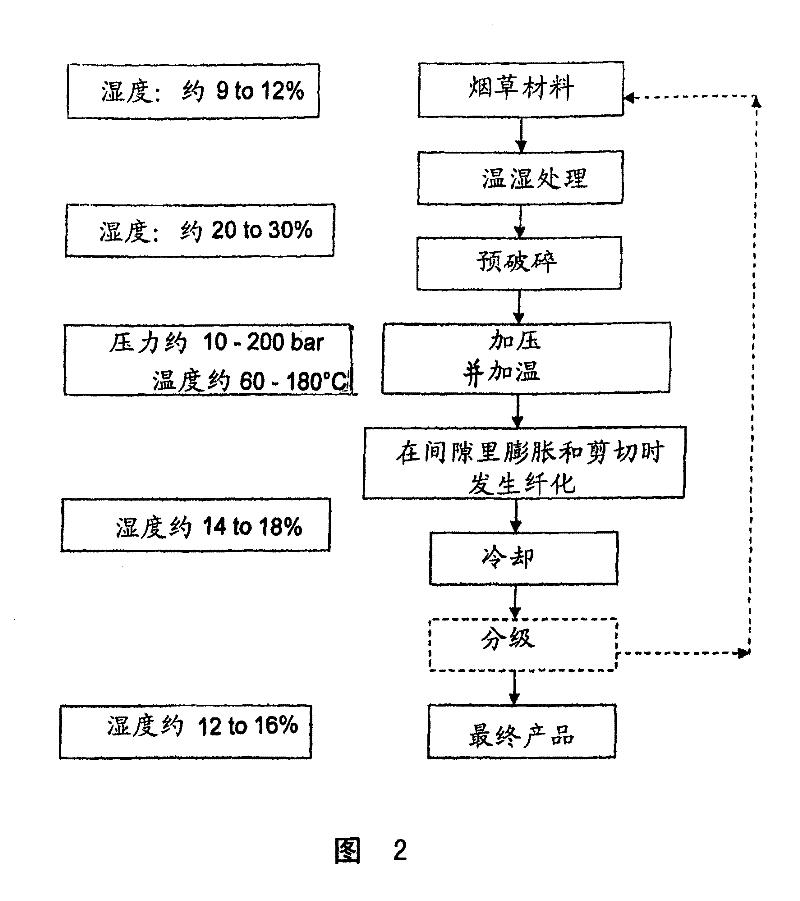

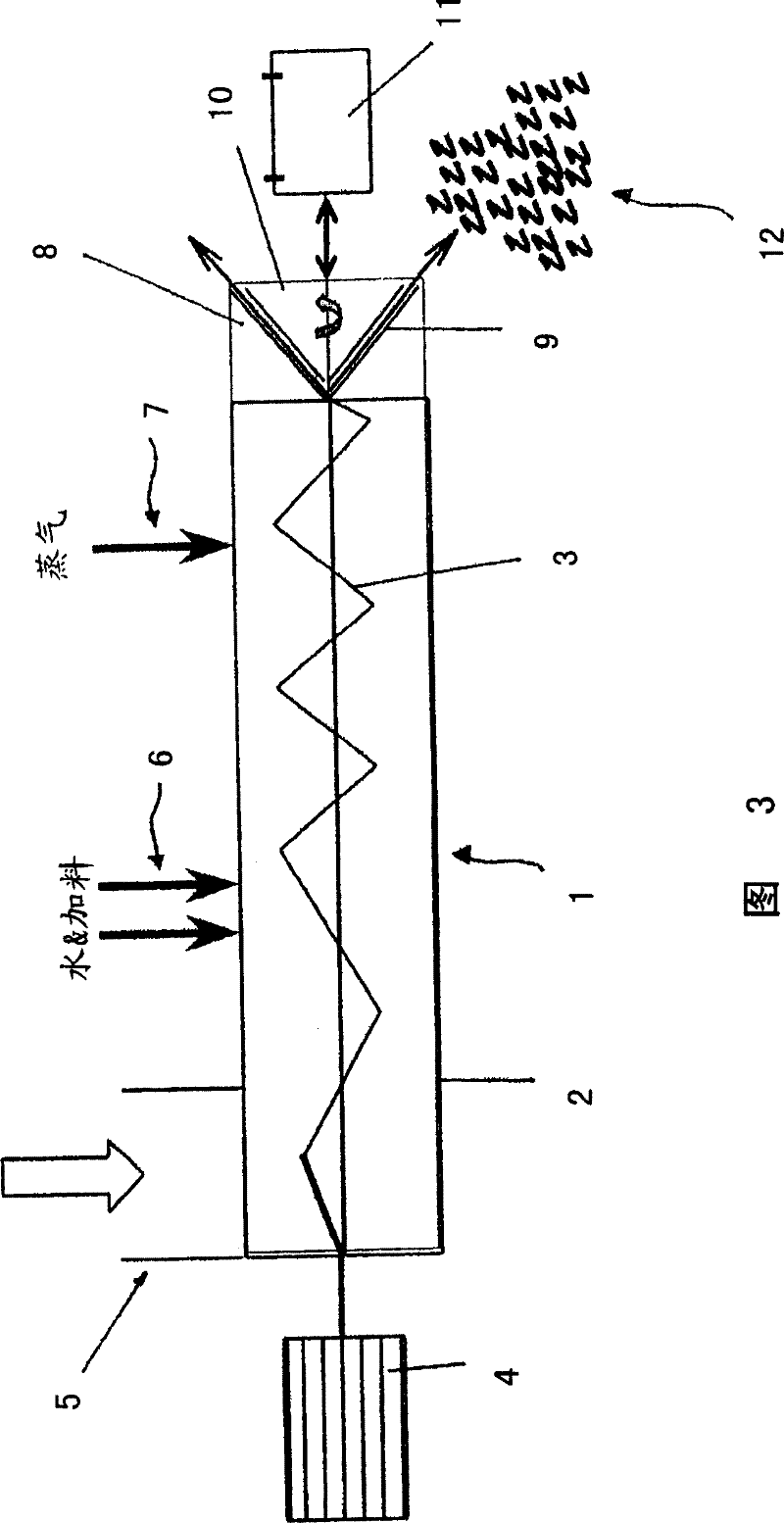

[0038] First refer to the following figure 1 and 2 DETAILED DESCRIPTION A pressurized fiberizing system according to the invention is arranged in a tobacco manufacturing process.

[0039] figure 1 The tobacco manufacturing process is schematically shown generally in terms of application from the raw stem to the final product.

[0040] Humidity values are stated on a moisture basis and are recommended and preferred values. Optimum conditions can be set if the specialist follows the basic concept of the invention and adapts to the optimum conditions of a device according to the invention (expansion device).

[0041] Raw stems are usually entered at about 10% humidity for thermohumidification. The temperature-humidity treatment can be carried out under atmospheric conditions, advantageously under superatmospheric pressure, as described, for example, in the aforementioned DE 103 04 629 A1. Additives and fragrances can also be added during the temperature-humidity treatment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com