Chip washing equipment preventing blocking of pipe wall

A chip and tube wall technology, which is applied in the field of chip cleaning equipment with the function of preventing tube wall clogging, can solve the problems of clogging pipelines, waste of time, particles adhering to the tube wall, etc., to avoid clogging and prevent tube wall clogging. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

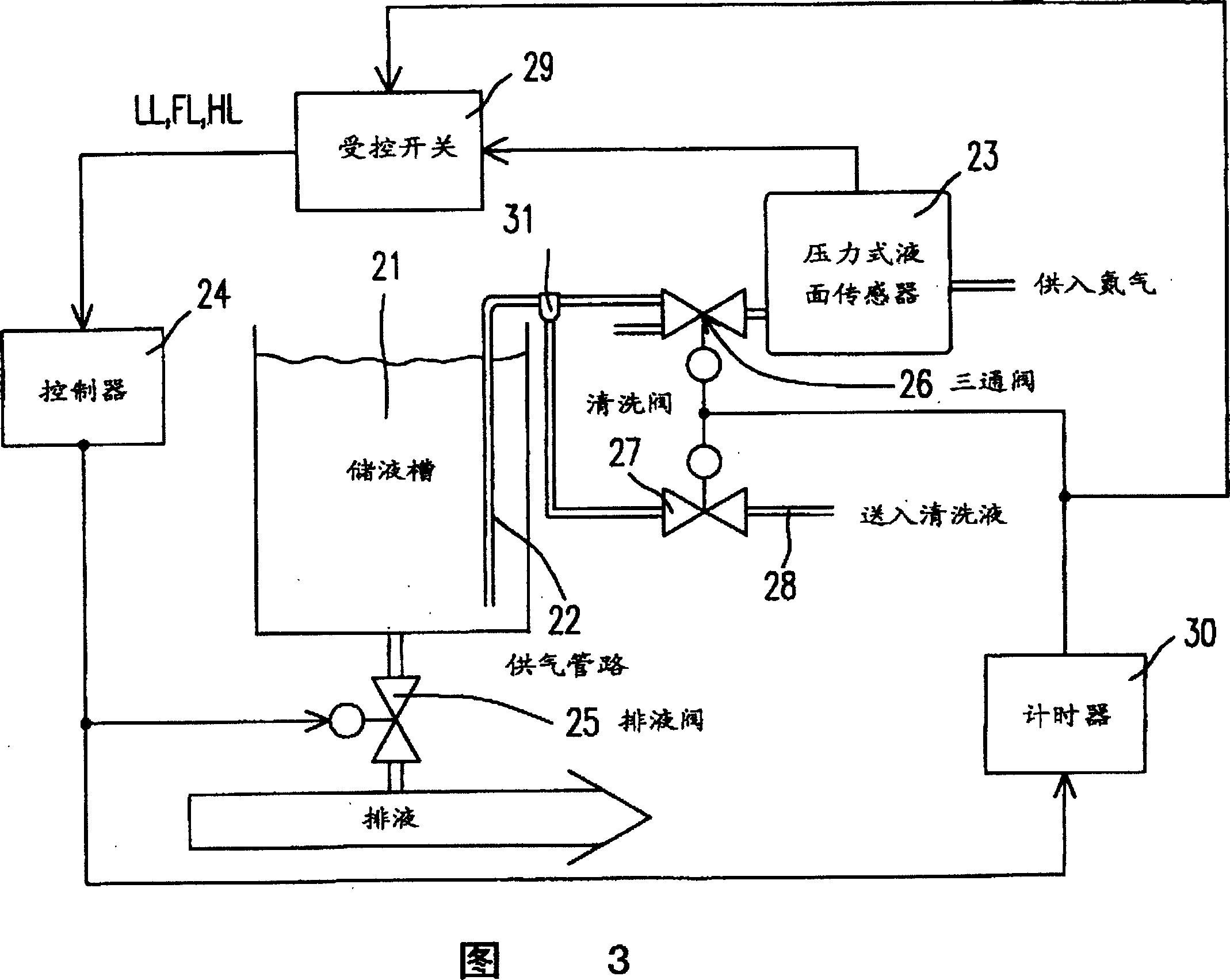

[0023] Please refer to FIG. 3 , which is a schematic structural diagram of a chip cleaning device according to a preferred embodiment of the present invention. As shown in the figure, it includes a cleaning solution storage device composed of a liquid storage tank 21, a controller 24 and a liquid discharge valve 25, a gas supply pipeline 22 for the liquid discharge valve, a pressure type liquid level sensor 23 and an automatic cleaning device. The cleaning solution required for cleaning the chip is stored in the liquid storage tank 21 , such as buffer oxide etchant (Buffer HF, BHF for short or Buffer Oxide Etcher, BOE for short). The gas supply pipeline 22 passes an inert gas into the buffered oxide layer etchant stored in the liquid storage tank 21, wherein the air pressure in the gas supply pipeline 22 is washed with the liquid storage tank 21. The liquid level of the cleaning solution changes, so it can cooperate with the pressure type liquid level sensor 23 to detect the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com