Rare earth/polymer composite luminous material and its preparation method

A technology of luminescent materials and polymers, which is applied in the field of rare earth/polymer composite luminescent materials and its preparation, can solve the problems of low luminous efficiency of rare earth particles and lack of the most effective way to improve the luminous intensity of rare earth ions, and achieve improved luminous intensity, luminous High strength, the effect of increasing the amount of rare earth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

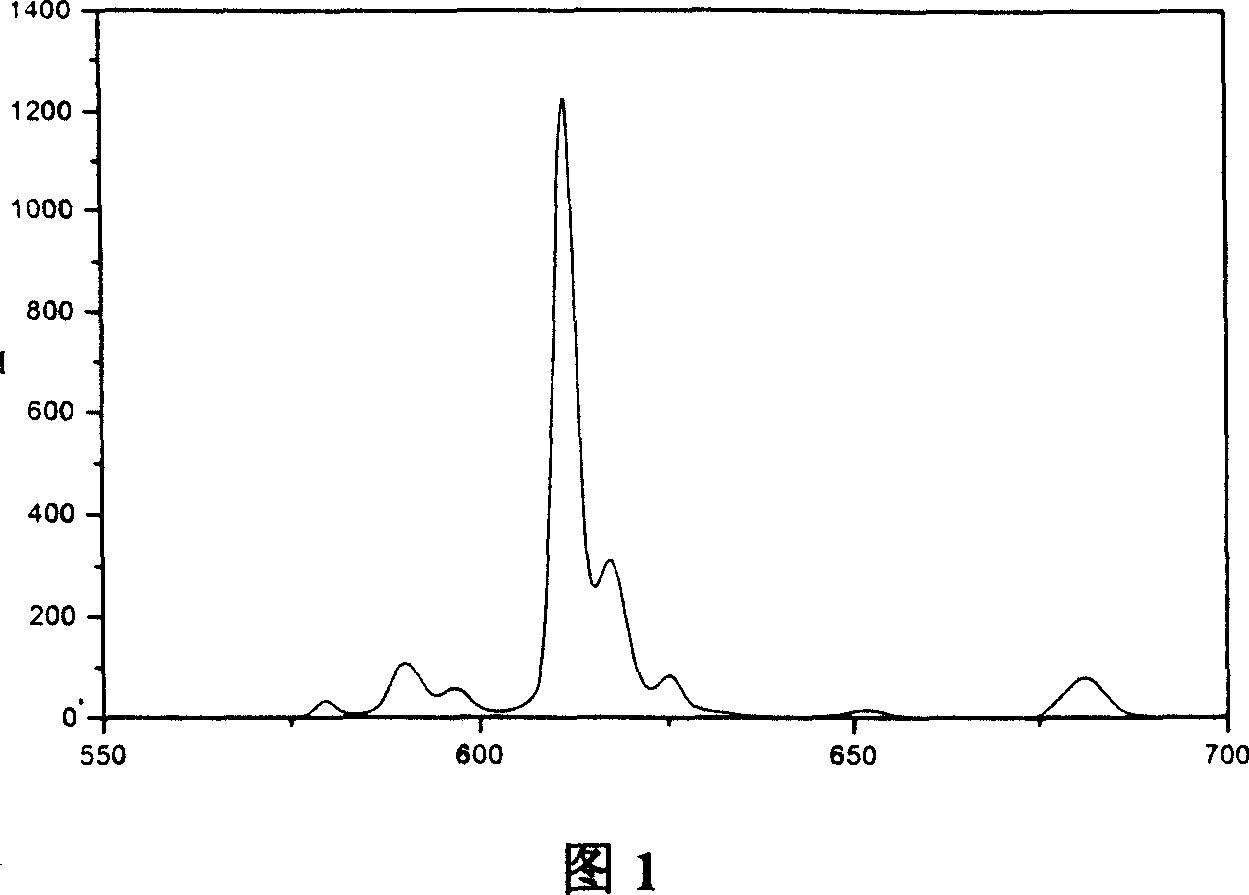

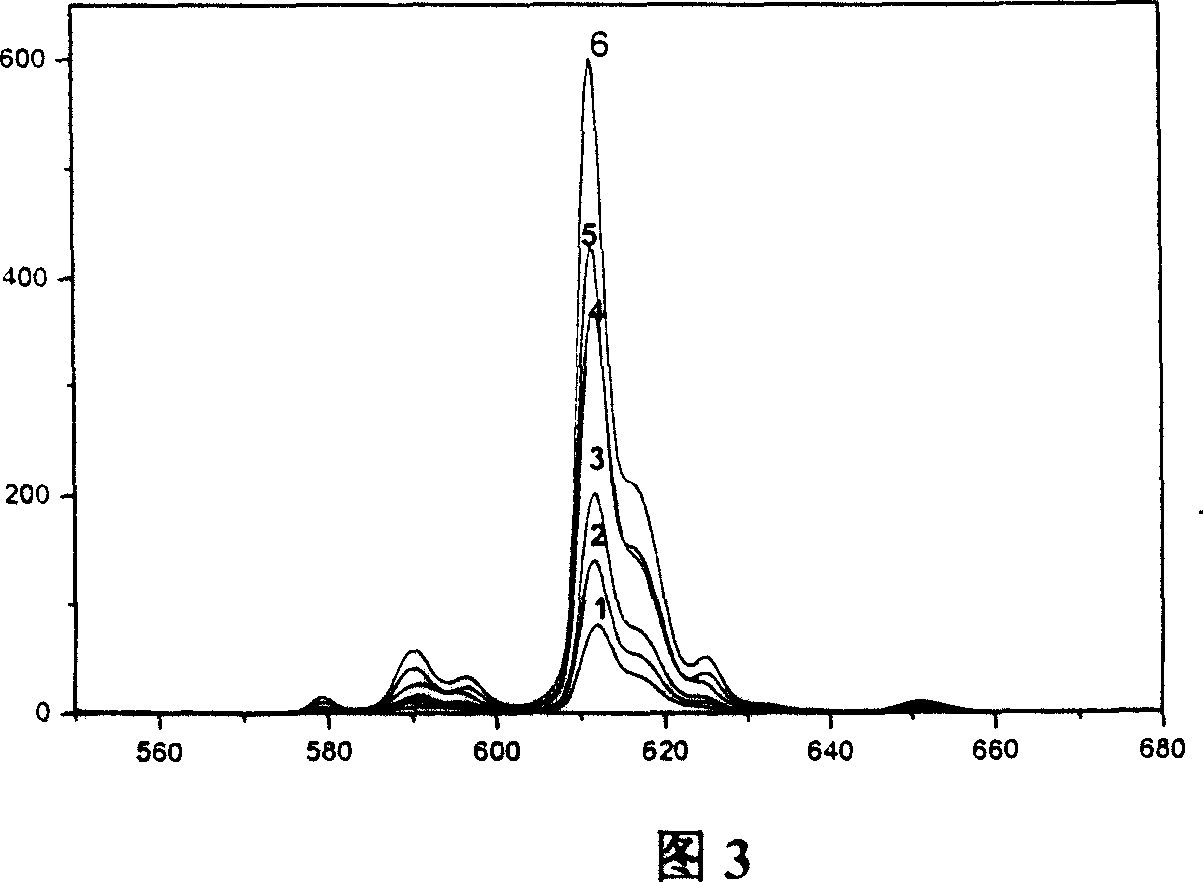

[0026] Example 1: first react the rare earth oxide with 1:1 hydrochloric acid and convert it into the rare earth chloride SmCl 3, then mix this chloride solution with TTA, HAA and phen in a molar ratio of 1:2:1:1, react at 60°C for 2 hours, adjust the pH value of the solution to 5-6 with a 1:1 ammonia solution, Stand still at room temperature, filter, and the product is placed in a vacuum oven at 80°C overnight to prepare (Sm(TTA) 2 (AA)phen), 100 parts of nitrile rubber (NBR), and rare earth organic complex (Sm(TTA) 2 (AA) phen) composite material composed of 2 parts.

[0027] Implementation of in-situ reaction and preparation of composite materials: run the mill at room temperature, add 100g NBR to make it roll, add rare earth organic complex (Sm(TTA) 2 (AA)phen) 2g, mix well, add 3g double 2,5 after eating powder, make ten triangle bags, evenly slice, then place in a 10cm×6cm×2cm mold, pressurize and exhaust, the pressure is 100kg / cm 2 After pressing for 15 minutes (in s...

Embodiment 2

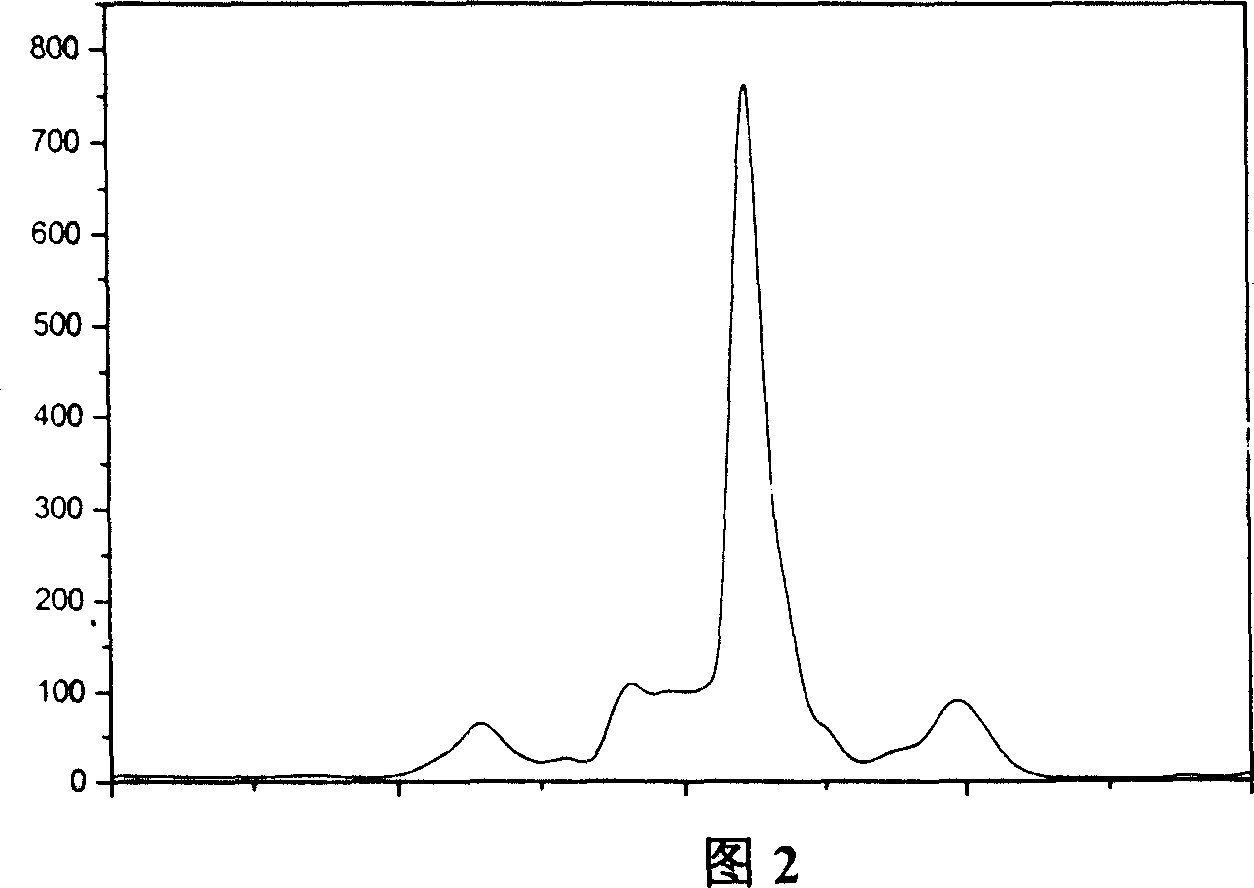

[0028] Embodiment 2: 100 parts of nitrile rubber (NBR), with the rare earth organic complex (Sm(TTA) prepared in embodiment 1 2 (AA) phen) composite material composed of 5 parts. Implementation of in-situ reaction and preparation of composite materials: run the mill at room temperature, add 100g NBR to make it roll, add rare earth organic complex (Sm(TTA) 2 (AA)phen) 5g, mix well, add 3g double 2,5 after eating powder, make ten triangular bags, the next piece is uniform, and then placed in a 10cm×6cm×2cm mold, pressurized and exhausted, the pressure is 100kg / cm 2 After pressing for 15 minutes (in situ reaction occurs at this stage), the mold was taken out to take out the sample.

Embodiment 3

[0029] Embodiment 3: 100 parts of nitrile rubber (NBR), with the rare earth organic complex (Sm(TTA) prepared in embodiment 1 2 (AA) phen) composite material consisting of 8 parts. Implementation of in-situ reaction and preparation of composite materials: run the mill at room temperature, add 100g NBR to make it roll, add rare earth organic complex (Sm(TTA) 2 (AA)phen) 8g, mix well, add 3g double 2,5 after eating powder, make ten triangle bags, the next piece is uniform, and then placed in a 10cm×6cm×2cm mold, pressurized and exhausted, the pressure is 100kg / cm 2 After pressing for 15 minutes (in situ reaction occurs at this stage), the mold was taken out to take out the sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com