Dishing spring type press mould

A disc spring and molding technology, applied in the field of disc spring molding die, can solve the problems of reduced die life, increased wear and high cost, and achieve the effect of avoiding unnecessary wear, improving product qualification rate and improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the embodiments of the above-mentioned drawings.

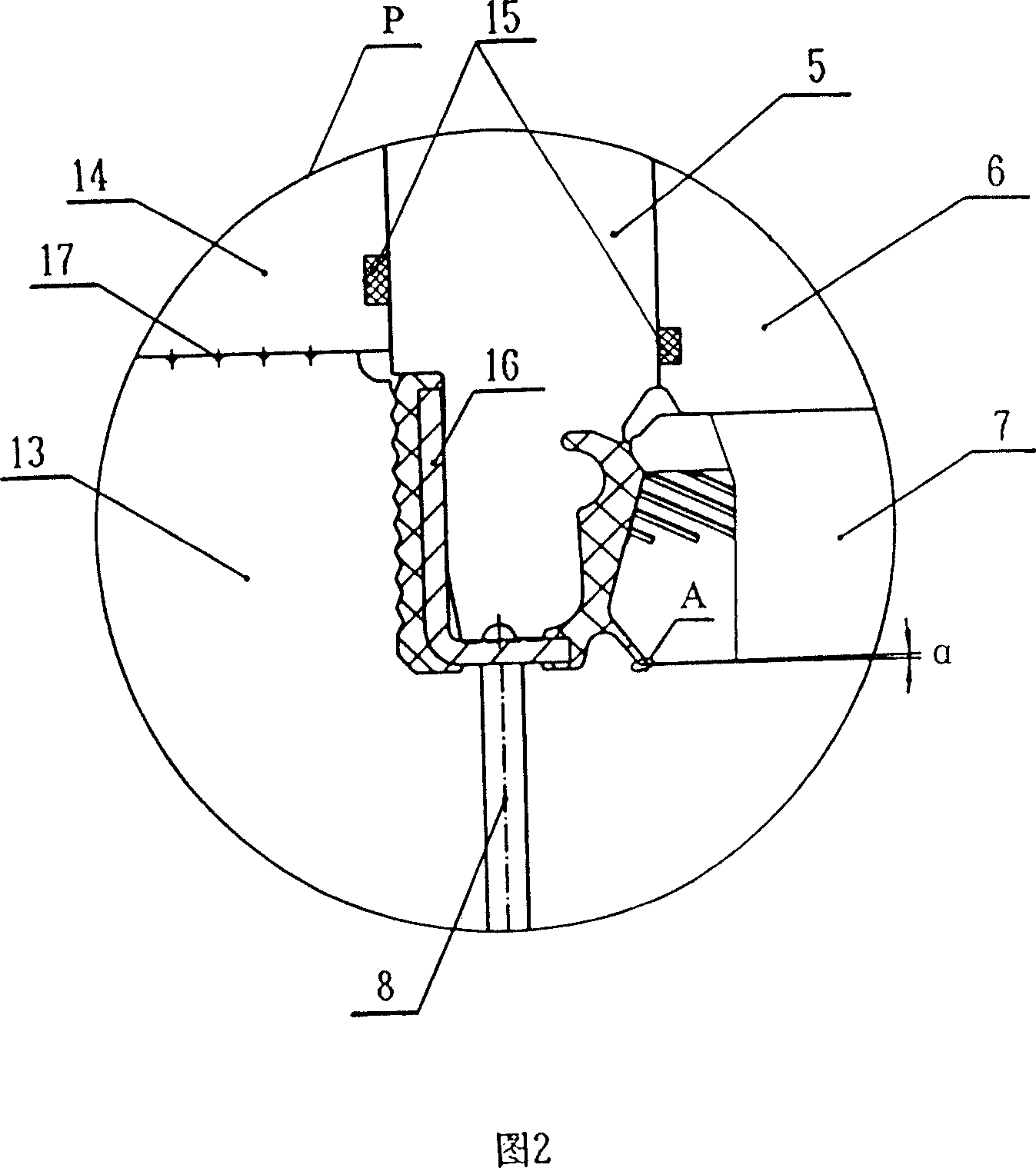

[0019] Referring to Fig. 1-Fig. 2, the overall structure of the disc spring molding die is in the shape of a cylinder, and is installed in the upper and middle templates (not shown) that can be separated above the lower template of the molding machine. The following embodiments are introduced by taking the skeleton oil seal with a size of 85×105×12 (mm) as an example: it includes an upper mold backing plate 1 and an upper mold 14, and an insert 6 and a spring groove of the insert 6 are installed in the upper mold backing plate There is a retaining spring 3 inside which acts as a limiter. The retaining spring not only prevents the insert 6 from falling down, but also prevents the backing plate of the upper die from falling out of the mold when the mold is inverted. The top surface of the insert 6 is lower than the upper die pad. The top surface o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com