Adjustable extemal cavity laser

A technology of laser cavity and laser equipment, used in lasers, laser parts, semiconductor lasers, etc., can solve the problems of tunable external cavity laser size, cost, complexity and sensitivity increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

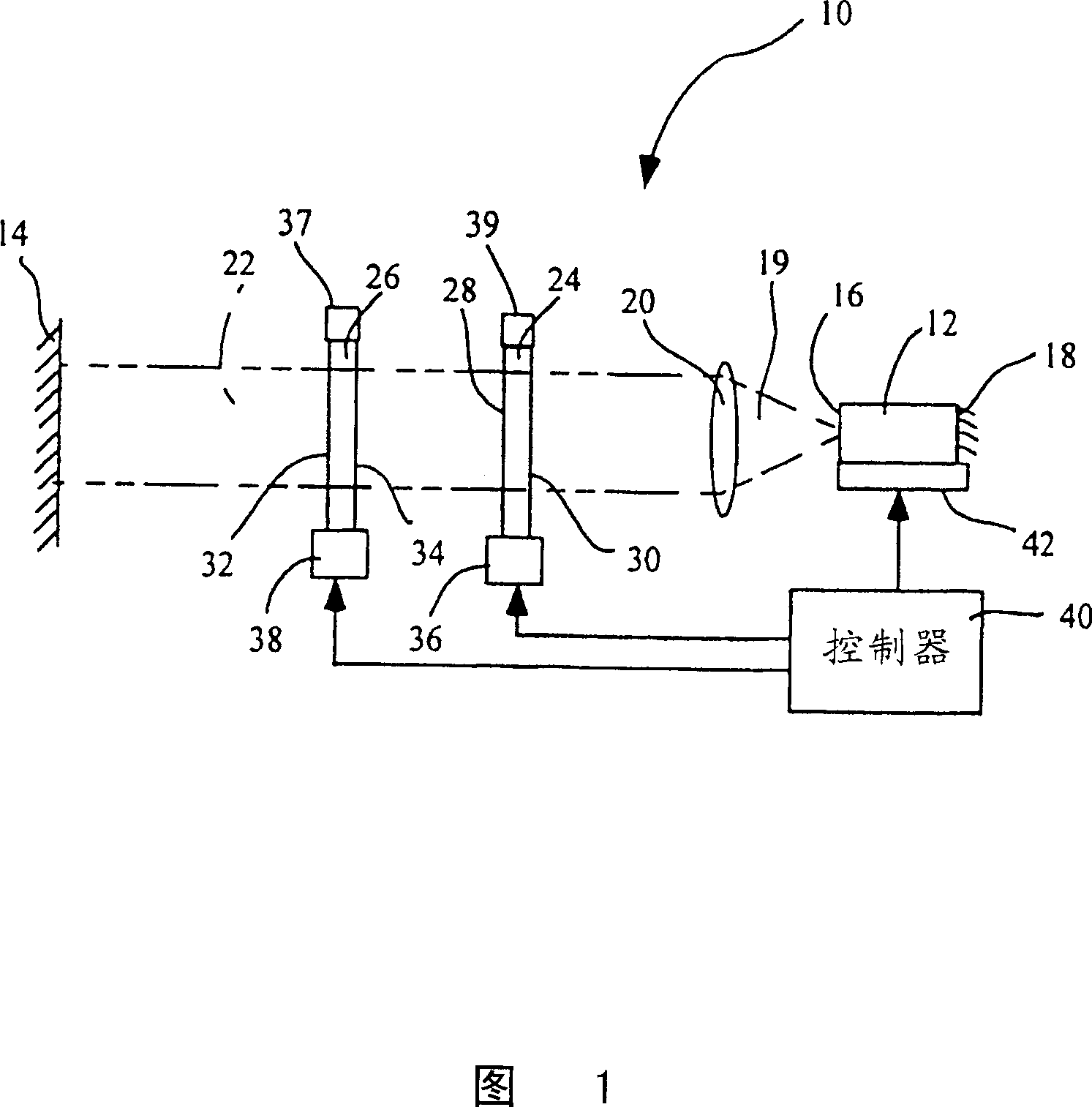

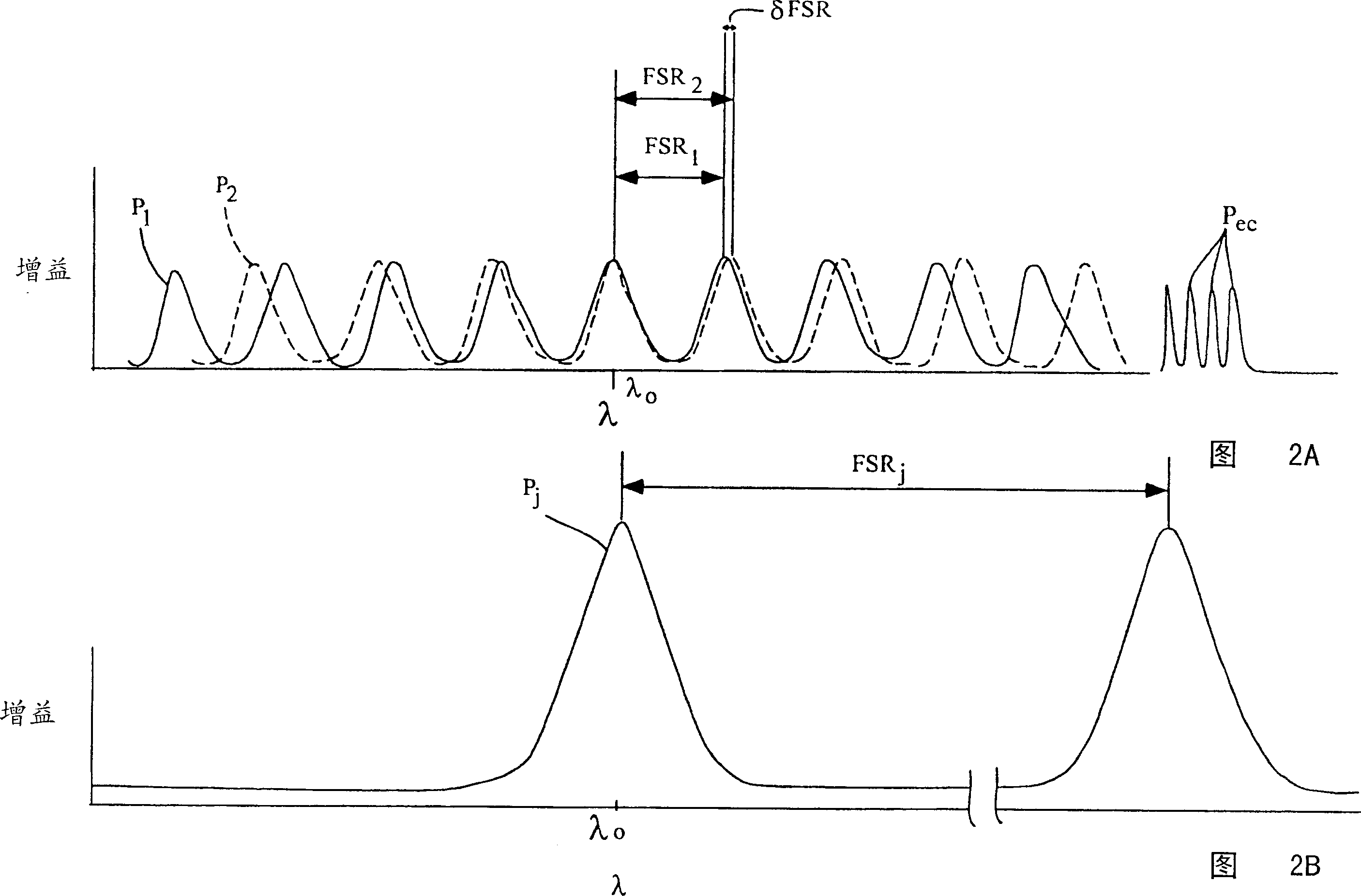

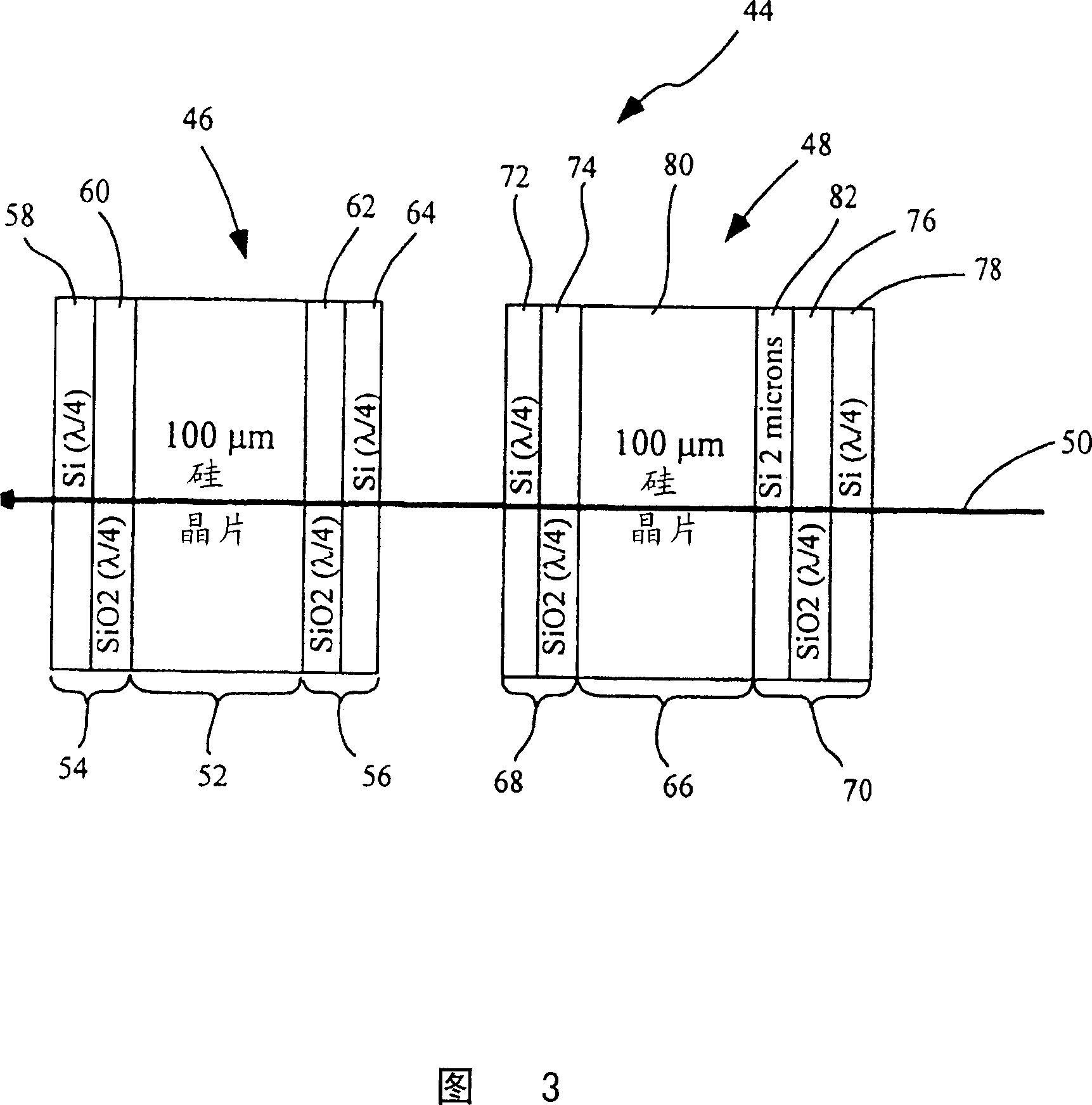

[0040] Reference is made more particularly to the drawings for the purpose of illustrating the invention embodied in the apparatus shown in FIGS. 1 to 17 . It should be understood that the device may vary in configuration and detail of components, and the method may vary in detail and order of actions without departing from the basic concept disclosed. The invention is primarily disclosed in terms of the use of external cavity lasers. However, the invention can be used with various types of laser devices and optical systems. It is to be understood that the terminology used herein is for the purpose of describing particular embodiments only and is not limiting, since the scope of the present invention is defined only by the claims. The relative sizes of components, as well as the distances between them, shown in the figures are of many examples exaggerated for clarity and therefore should not be considered limiting.

[0041] Referring to Figure 1, there is shown a laser devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com