Connecting and forming composite method for sedan sky light zinc plating frame

A galvanized sheet and frame technology, used in welding power sources, welding equipment, energy storage discharge welding, etc., can solve the problems of difficult to guarantee welding quality and surface quality, poor overall product rigidity, complex workpiece shape, etc. Solving problems, low cost of welding equipment, and the effect of meeting mass production requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1, the specific implementation process of applying the inventive method to complete the POLO sunroof frame is as follows:

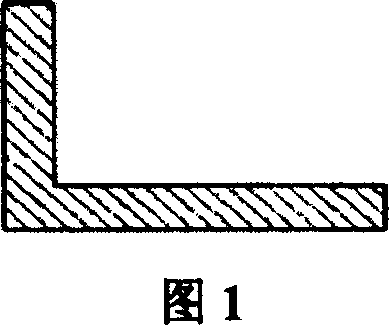

[0021] 1. Blanking the galvanized sheet into a right-angled flat piece. The grade of the galvanized sheet is BUFDE+Z produced by Baosteel, with a thickness of 0.5mm and a width of 50mm. On this basis, the punching and embossing processes are completed.

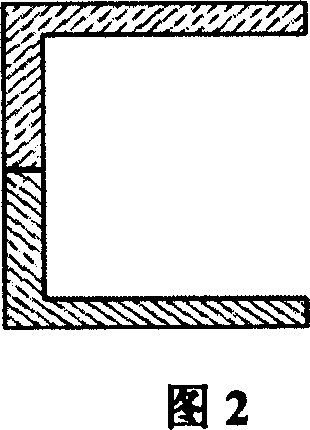

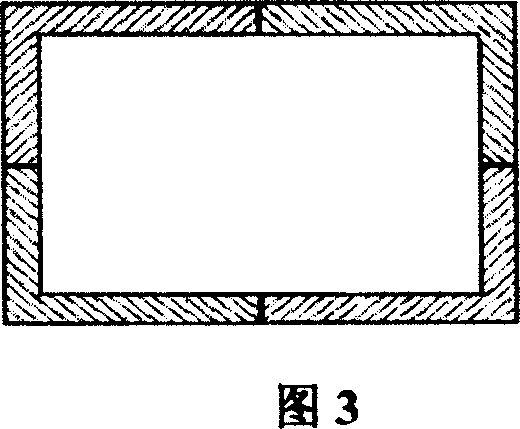

[0022] 2. After positioning the right-angle flat sheet overlapping 1.5mm up and down, it is welded into a half-frame-shaped flat-plate frame by a flattening capacitor energy storage welding method, and then the half-frame-shaped flat-plate frame is welded into a square flat-plate frame.

[0023] 3. In the stamping die, the entire square flat frame is flanged to 90° at one time.

[0024] Step 4: Carry out the second flanging of the entire frame in the stamping mold, firstly preform the flanging at 45°, then flanging to 90° and shaping the whole frame.

[0025] This embodiment has high we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com