Cylindrical lens component and producing method, rear projection screen and rear-projection television

A cylindrical mirror and component technology, applied in the optical field, can solve the problems of black stripes and manufacturing difficulties, and achieve the effect of fine stripes, high resolution, and high contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

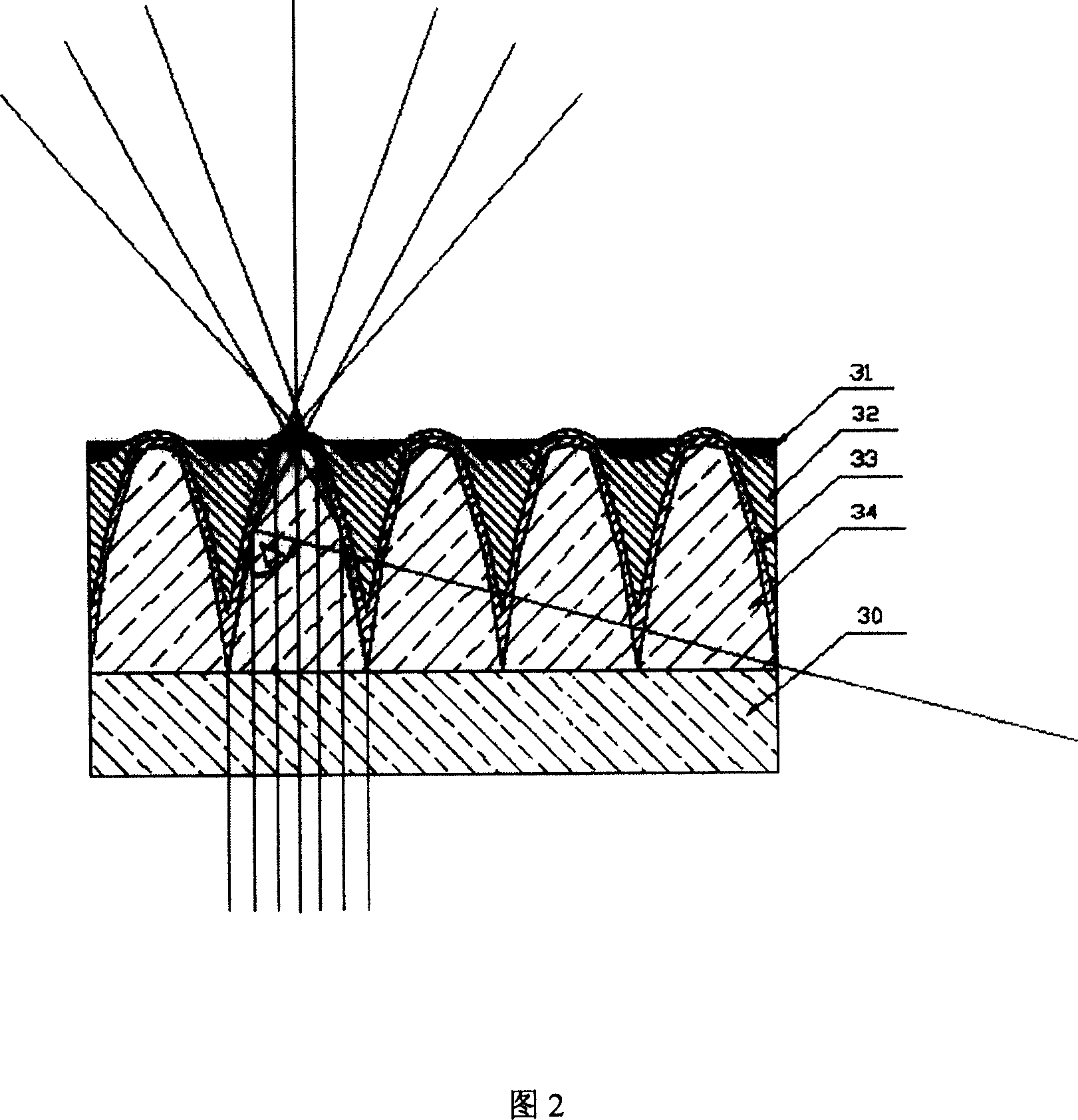

[0050] Referring to FIG. 2 , the surface of the cylindrical mirror array 34 is covered with a transparent material 33 , and the refractive index of the transparent material 33 is smaller than that of the cylindrical mirror material. A coating material 32 is filled between two adjacent cylindrical mirrors, and the light-absorbing stripes 31 are black stripes, and the black stripes are located between two adjacent cylindrical mirrors and on the coating material 32. The distance between two adjacent black stripes is not more than 0.25mm. The coating material 32 is photocurable glue or conductive material.

[0051] A transparent sheet (30) is also glued under the cylindrical lens array 34. As the unit of the cylindrical mirror array, the shape of the cylindrical mirror satisfies the following relationship:

[0052] Assuming that the final projected light energy has a spatial distribution function of f(θ), the projected light energy passes through the cylindrical mirror

[0053]...

Embodiment 2

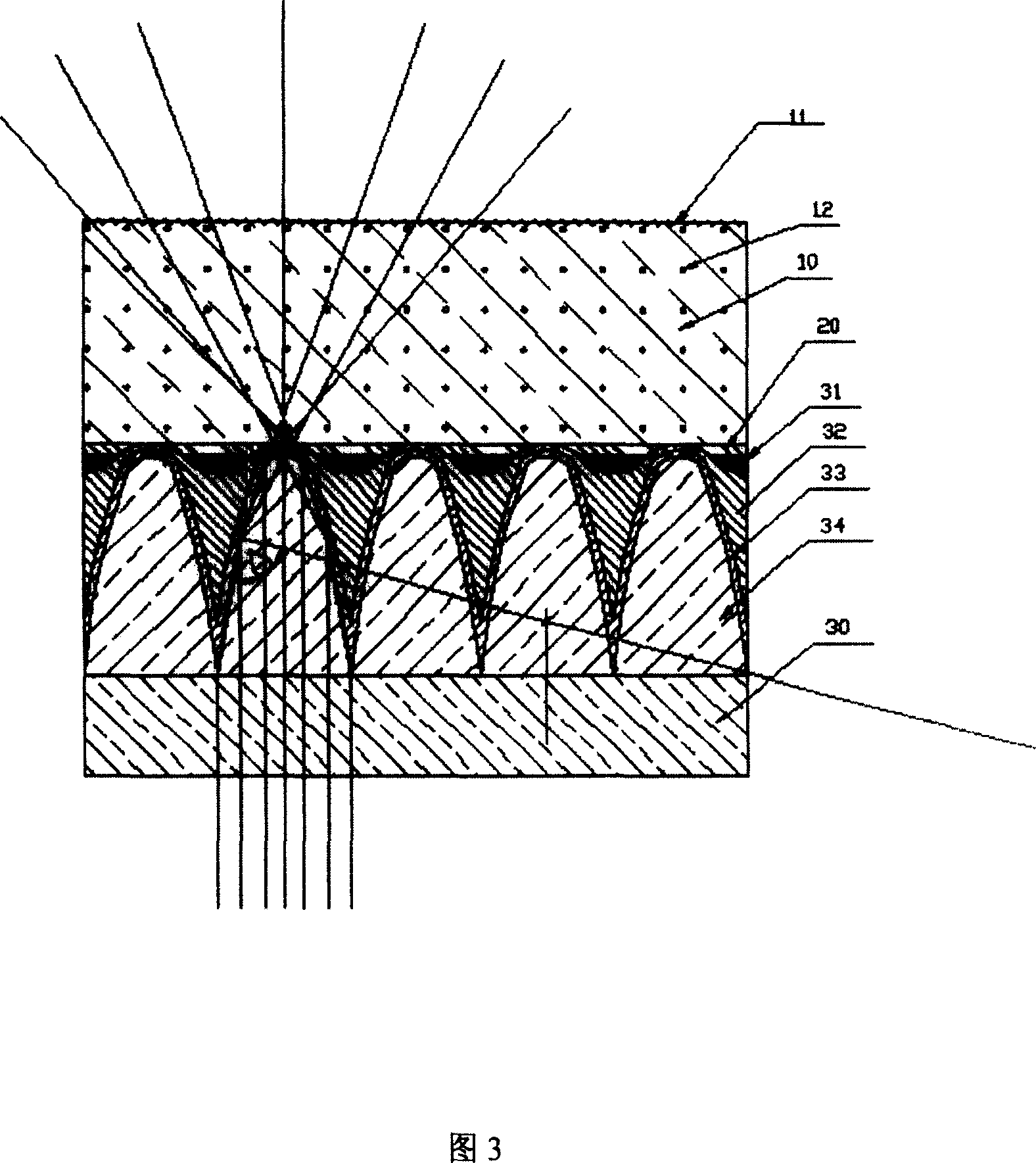

[0062] Referring to FIG. 4 , the difference between this embodiment and Embodiment 1 is that a scattering layer 10 is bonded above the cylindrical lens array 34 and the black stripes 31 , and the scattering layer 10 contains organic scattering particles 12 .

Embodiment 3

[0064] The difference between this embodiment and Embodiment 1 is that organic scattering particles 12 are distributed in the transparent material 33 . There is also a dielectric layer on the cylindrical lens array 34, and the surface of the dielectric layer is a fine matte surface. A low-reflection dielectric film can also be coated on the surface of the dielectric layer 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com