High negative pressure large flow rotary air valve

A large flow, rotary technology, applied in the field of negative pressure valves, can solve problems such as diaphragm rupture, high diaphragm requirements, and affecting double-clicking of letters, and achieve low air tightness requirements, low precision requirements, and good The effect of the separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

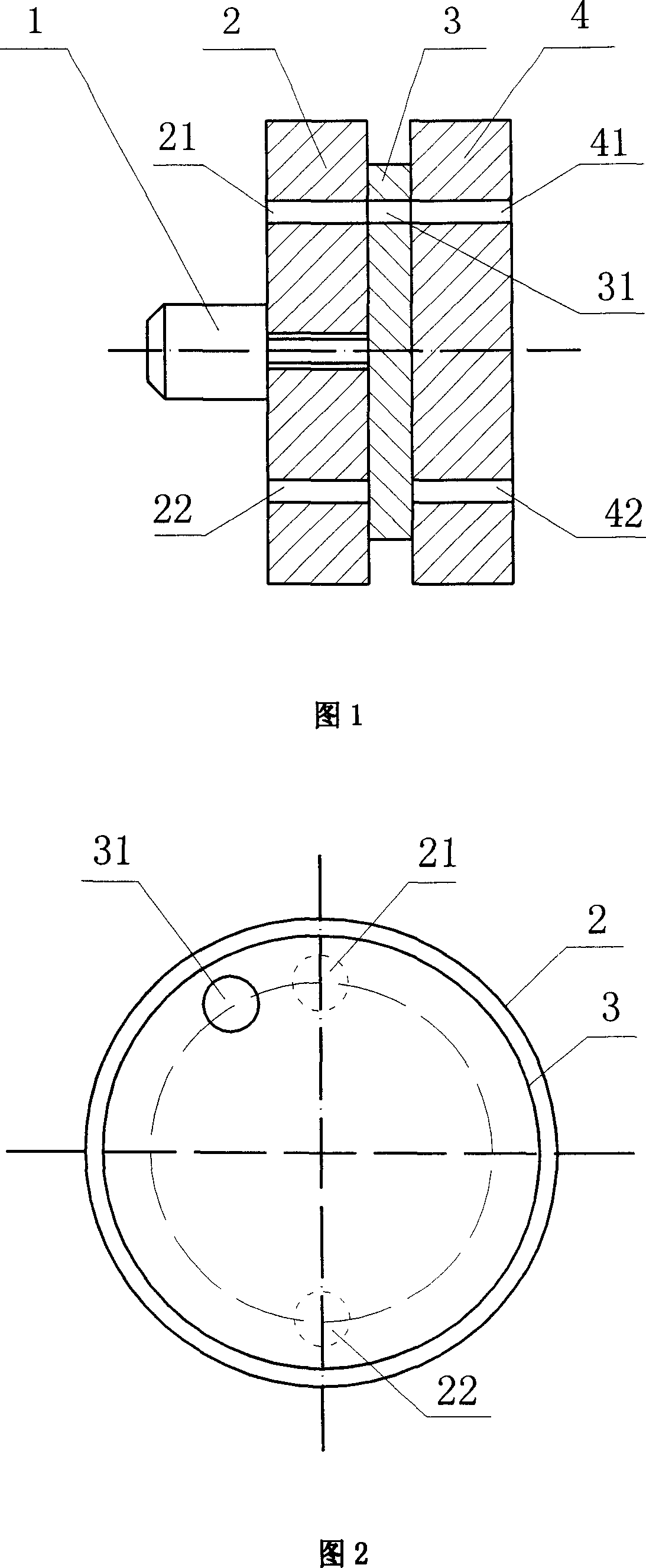

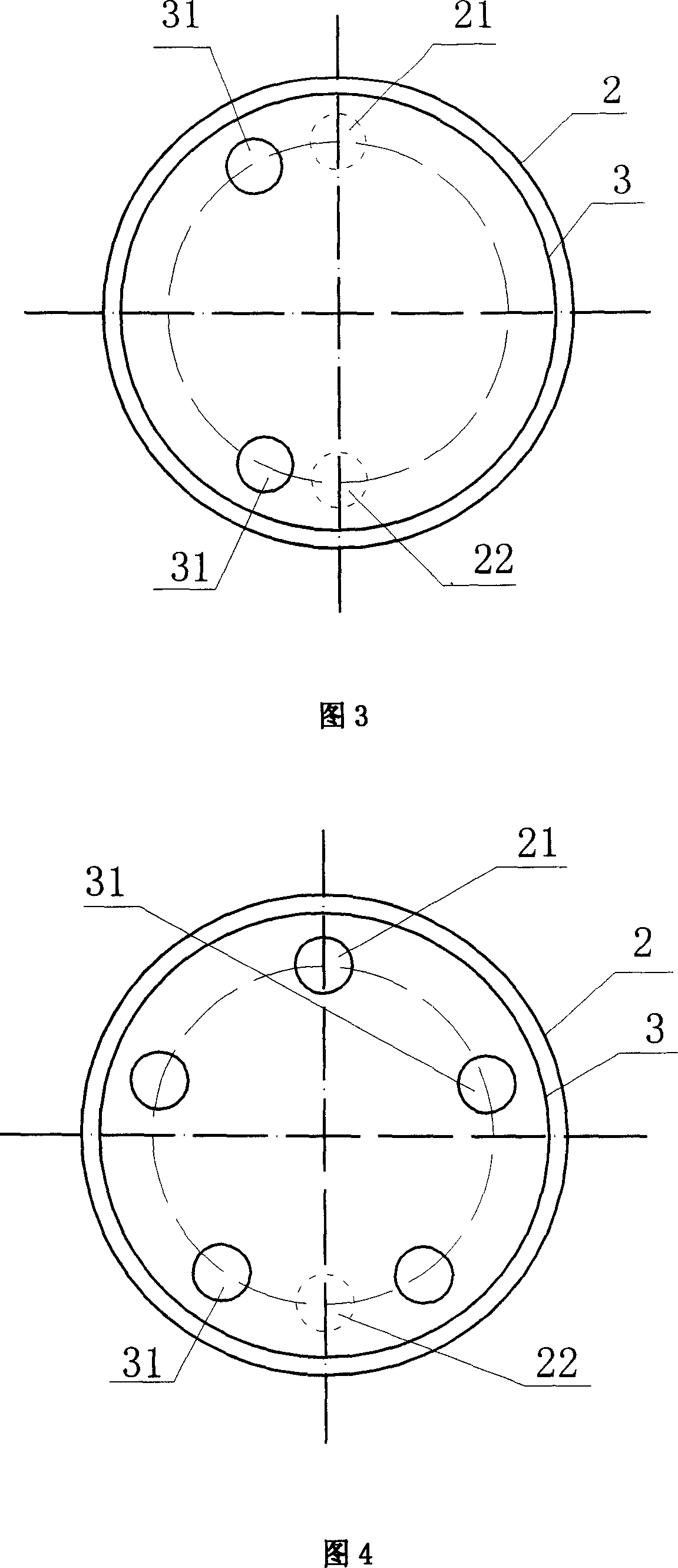

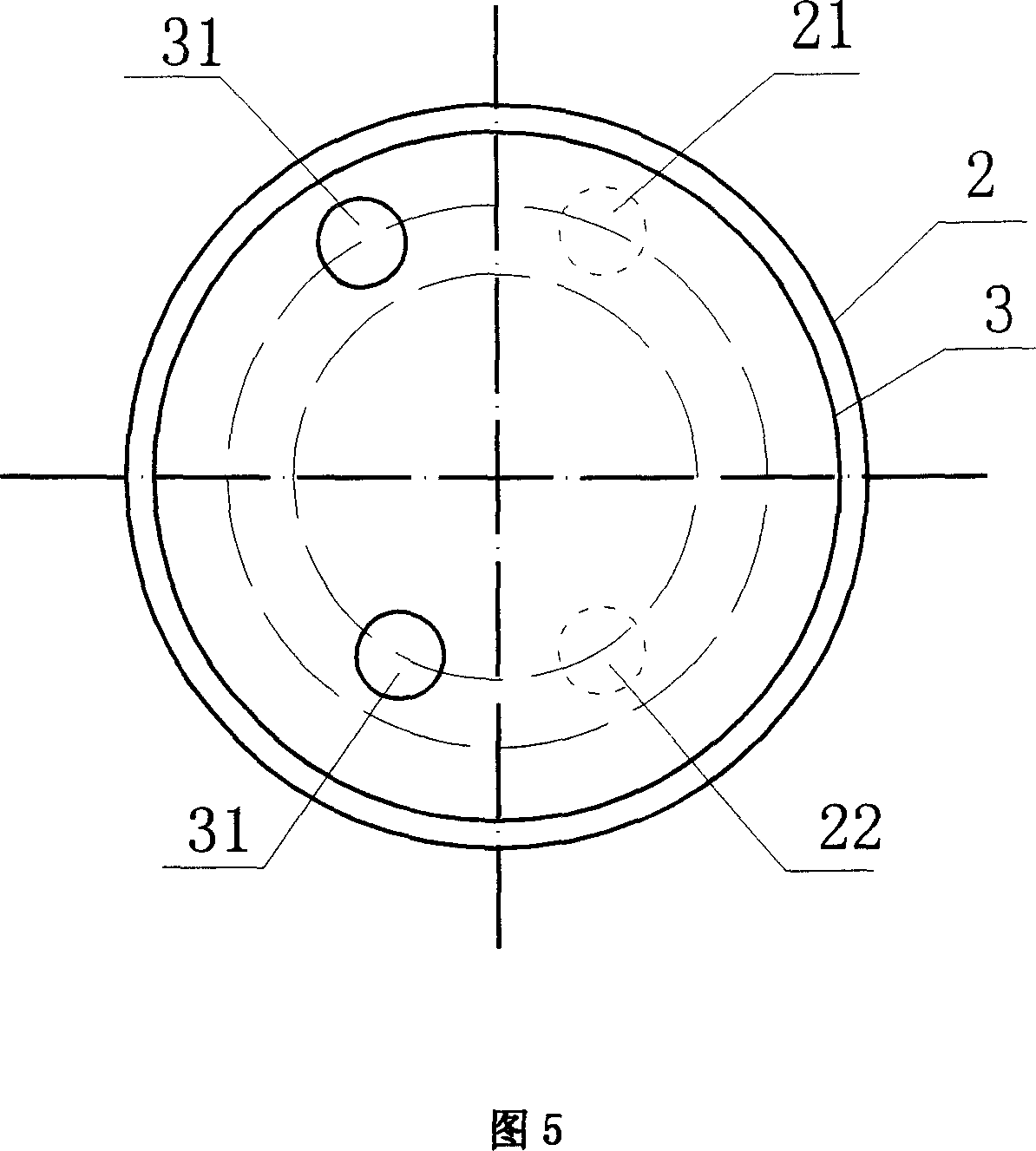

[0019] As shown in Figure 1 and Figure 2, the backplane 2, the turntable 3, and the suction plate 4 are closely fitted together, the servo motor 1 is installed on the backplane 2, and the central axis of the turntable 3 passes through the center hole of the backplane 2 and the servo Motor 1 is connected. There are two air holes 21, 22 on the back plate 2, and the air holes 21, 22 are connected with the negative pressure source during use. 3 is provided with a through hole 31, the rotation angle of the turntable 3 is controlled by the servo motor 1, the through hole 31 can make the first suction port 41 communicate with the first air hole 21 to generate negative pressure, at this time the second suction port 42 is sealed by the turntable 3 It is in the closed state; after a certain time interval, the servo motor 1 makes the turntable 3 rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com