Steel throttle gate capable of falling without middle mound

A technology for gates and middle piers, applied in the field of lodging steel gates without middle piers, which can solve the problems of high cost, water blocking, unfavorable flood drainage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

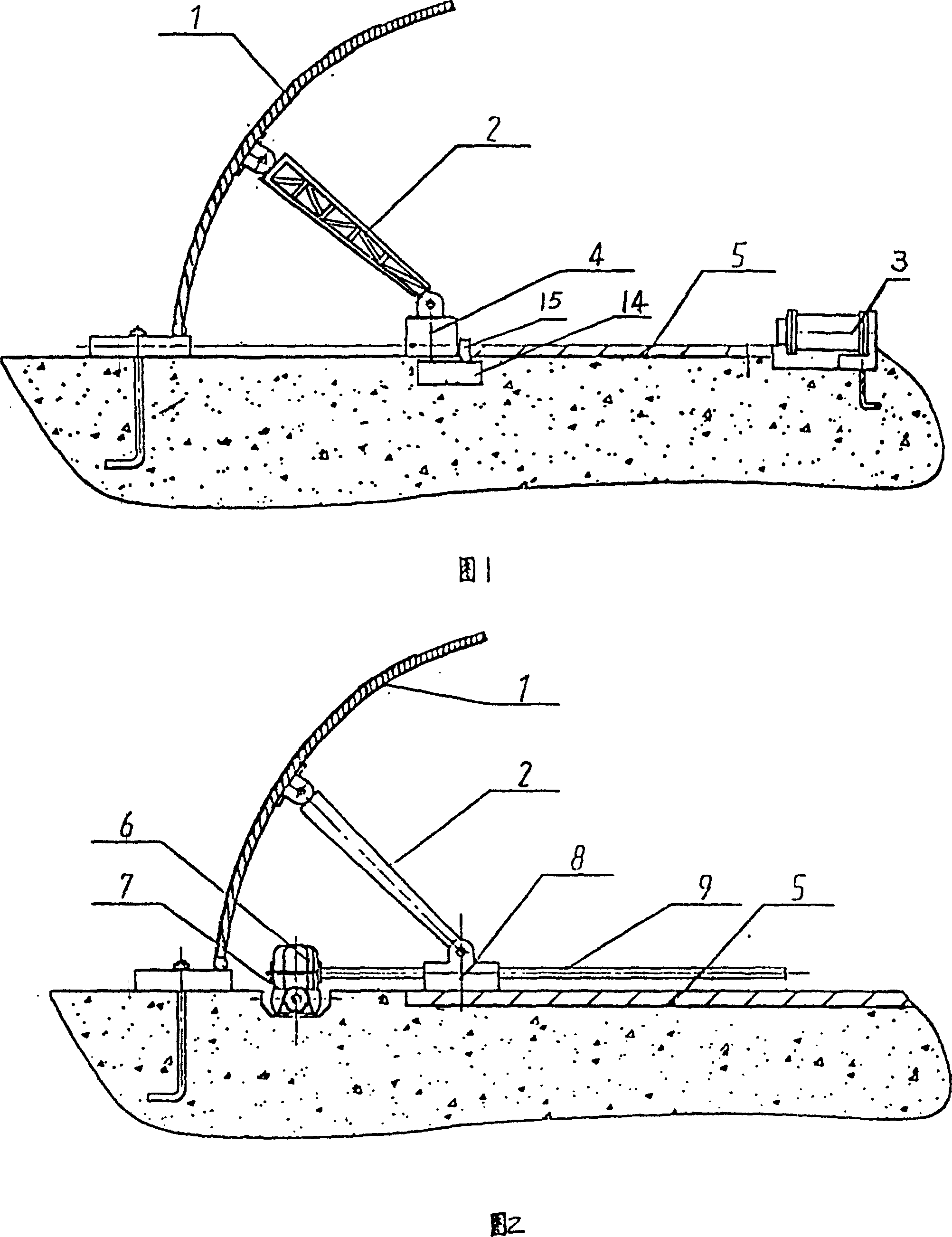

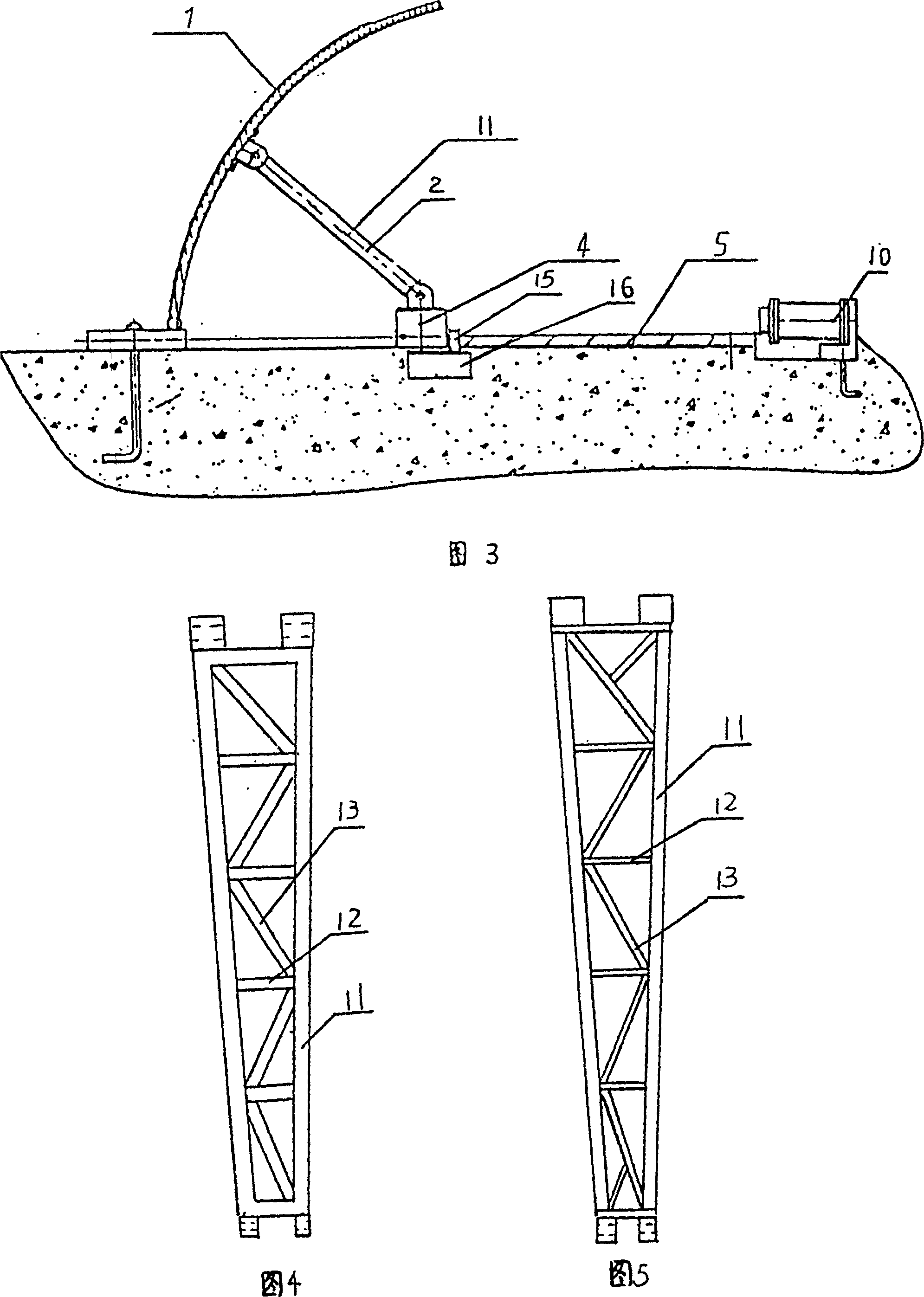

[0021] Embodiment 1: A kind of lodging steel gate without middle pier (refer to Fig. 1, Fig. 4), it has steel gate 1, and the two ends of steel gate 1 lower part are respectively connected with a supporting frame 2, and each supporting frame 2 is connected with a The slider 4, the support frame 2 has four longitudinal support rods 11, the upper ends of the longitudinal support rods 11 are inclined outward, the longitudinal support rods 11 are connected with the transverse support rods 12, and the transverse support rods 12 are connected with reinforcing ribs 13, each The sliders 4 are all arranged on the slideways 5 below, and each slideway 5 is connected to the riverway engineering floor, and the hydraulic device can push the sliders 4 to move on the slideway 5, and the hydraulic device has two multi-section oil cylinders 3 , each multi-section oil cylinder 3 is located at the rear end of the slideway 5, and the front end of each slideway 5 is provided with a rotary oil cylind...

Embodiment 2

[0022] Embodiment 2: A kind of lodging steel gate without middle pier (referring to Fig. 2, Fig. 5), it has steel gate 1, and the two ends of the lower part of steel gate 1 are respectively connected with a supporting frame 2, and each supporting frame 2 is connected Turn the nut 8, the support frame 2 has two longitudinal support rods 11, the upper ends of the longitudinal support rods 11 are inclined outwards, the longitudinal support rods 11 are connected with the transverse support rods 12, and the transverse support rods 12 are connected with reinforcing ribs 13, each Each rotating nut 8 is all connected with a passive rotating shaft 9, and each rotating nut 8 is all located on its glideway 5, and the slideway 5 is connected on the river engineering floor, and each passive rotating shaft 9 is connected with a mechanical transmission device, and the mechanical Transmission device has gearbox 6 that links to each other with passive rotating shaft 9, and gearbox 6 connects ac...

Embodiment 3

[0023] Embodiment 3: A kind of lodging steel gate without middle pier (see Fig. 3), it has a steel gate 1, the two ends of the lower part of the steel gate 1 are respectively connected with a support frame 2, and the support frame 2 is a longitudinal support rod 11 , each support rod 11 is connected with a slide block 4, each slide block 4 is located on the slideway 5 below it, and the slideway 5 is connected on the river engineering floor, and the pneumatic device can push each slide block 4 on the slide Move on the track 5, the pneumatic device has two cylinders 10, each cylinder 10 is all located at the rear end of the slideway 5, and the front end of each slideway 5 is all provided with a rotary cylinder 16, and the rotary cylinder 16 is connected with the lock block 15, each Each rotary cylinder 16 and each cylinder 10 are all connected to the air compressor, and the air compressor is connected to the motor. 5 slides, and when pushed to the front end of the slideway 5, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com