Working vehicle

一种变更操作、操作部件的技术,应用在农业、牵引车、机动车等方向,能够解决机体危险等问题,达到提高可靠性、防止操作偏差的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

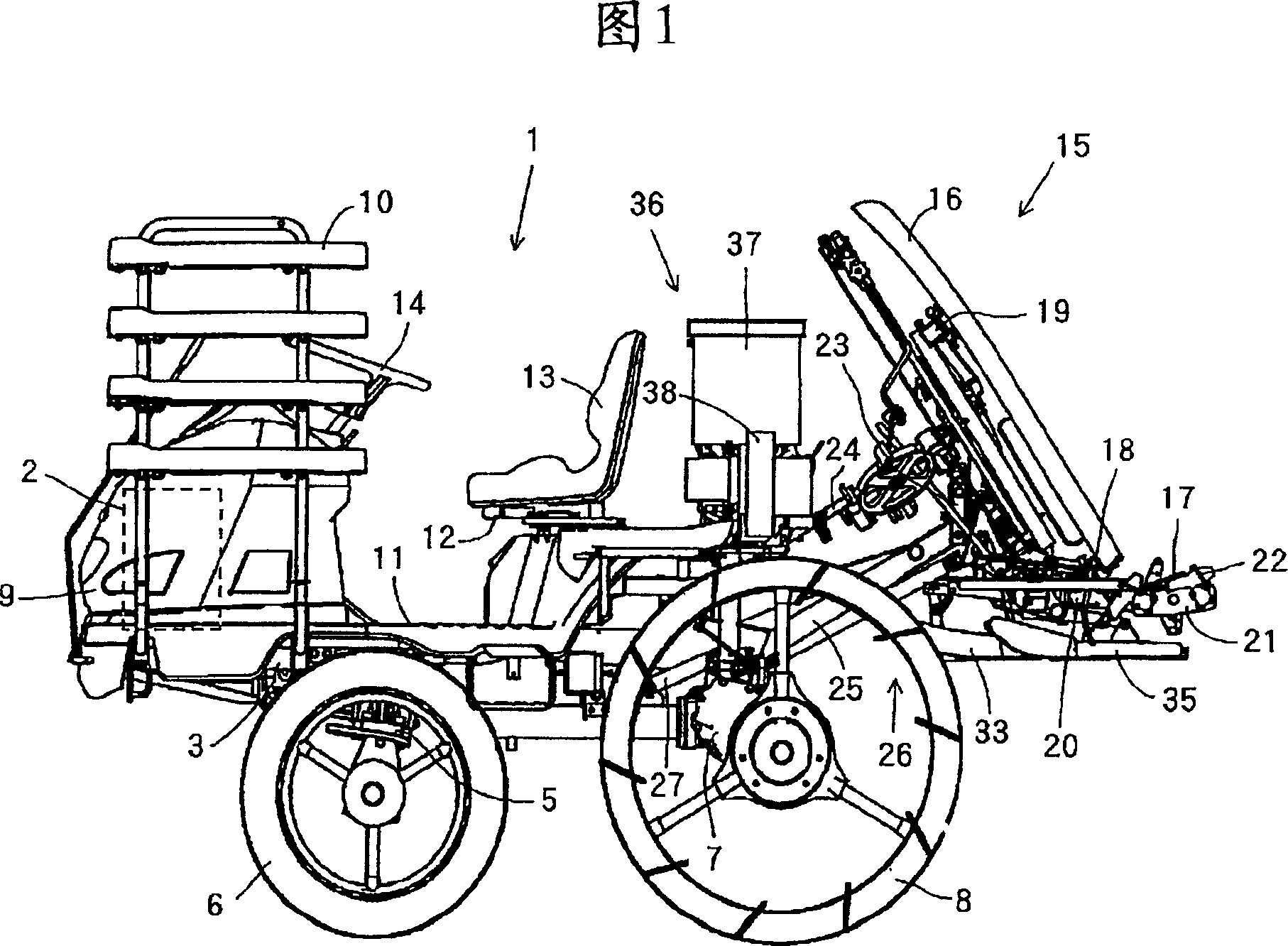

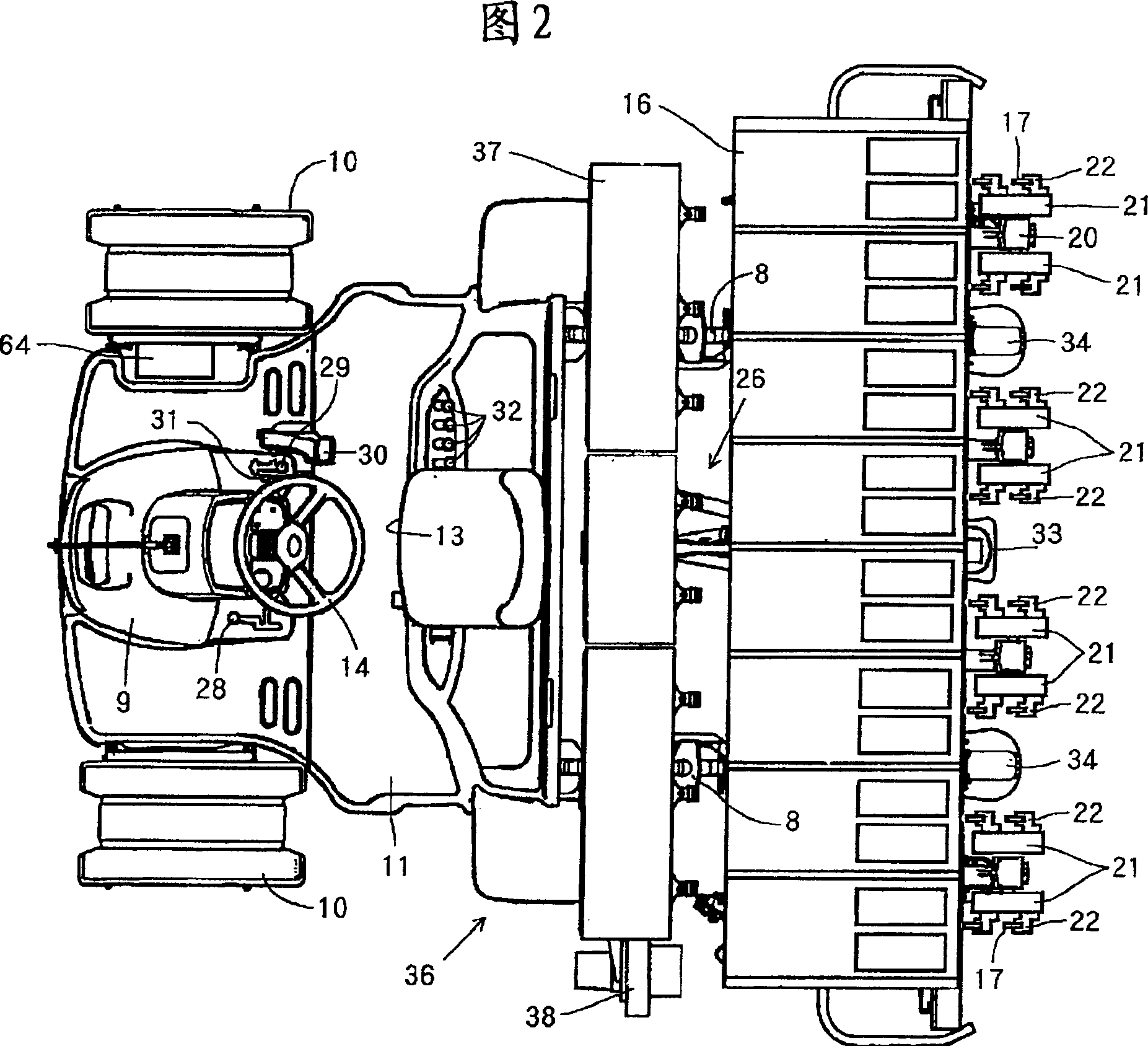

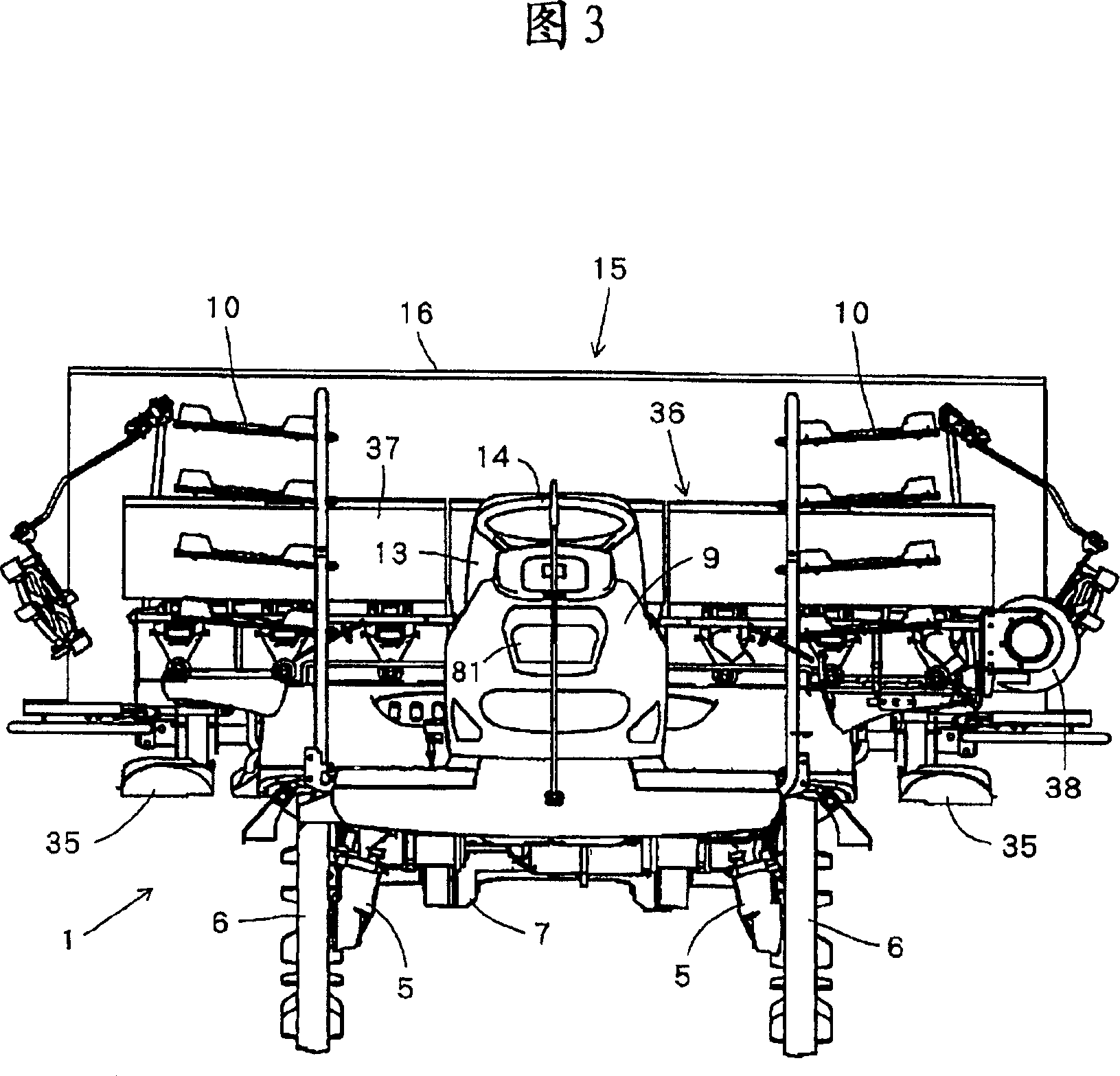

[0029] Hereinafter, embodiments of the present invention will be described in detail based on the drawings. Fig. 1 is the side view of the whole, Fig. 2 is its plan view, Fig. 3 is its front view, Fig. 4 is the side view of the car body, Fig. 5 is its plan view, among the figure 1 is the walking vehicle for carrying operators, air-cooled The engine 2 is mounted on the vehicle body frame 3, the front wheel 6 for paddy field walking is supported on the side of the gearbox 4 through the front axle box 5, and the rear wheel 8 for paddy field walking is supported on the rear axle box behind the above-mentioned gearbox 4. 7. And at the both sides of the hood 9 that covers the above-mentioned engine 2 etc., the preparatory seedling loading platform 10 is installed, and at the same time, the above-mentioned gearbox 4 etc. is covered with the car body cover 11 of the operator, and the driver's seat 13 is installed on the seat frame 12. Above the rear side of the vehicle body cover 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com