Technology for manufacturing tubular body of load-bearing frame for chair

A manufacturing method and bearing surface technology, applied in the field of chair components, can solve the problems of easy cracking of leather or cloth, broken wooden frame, broken cloth or leather, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

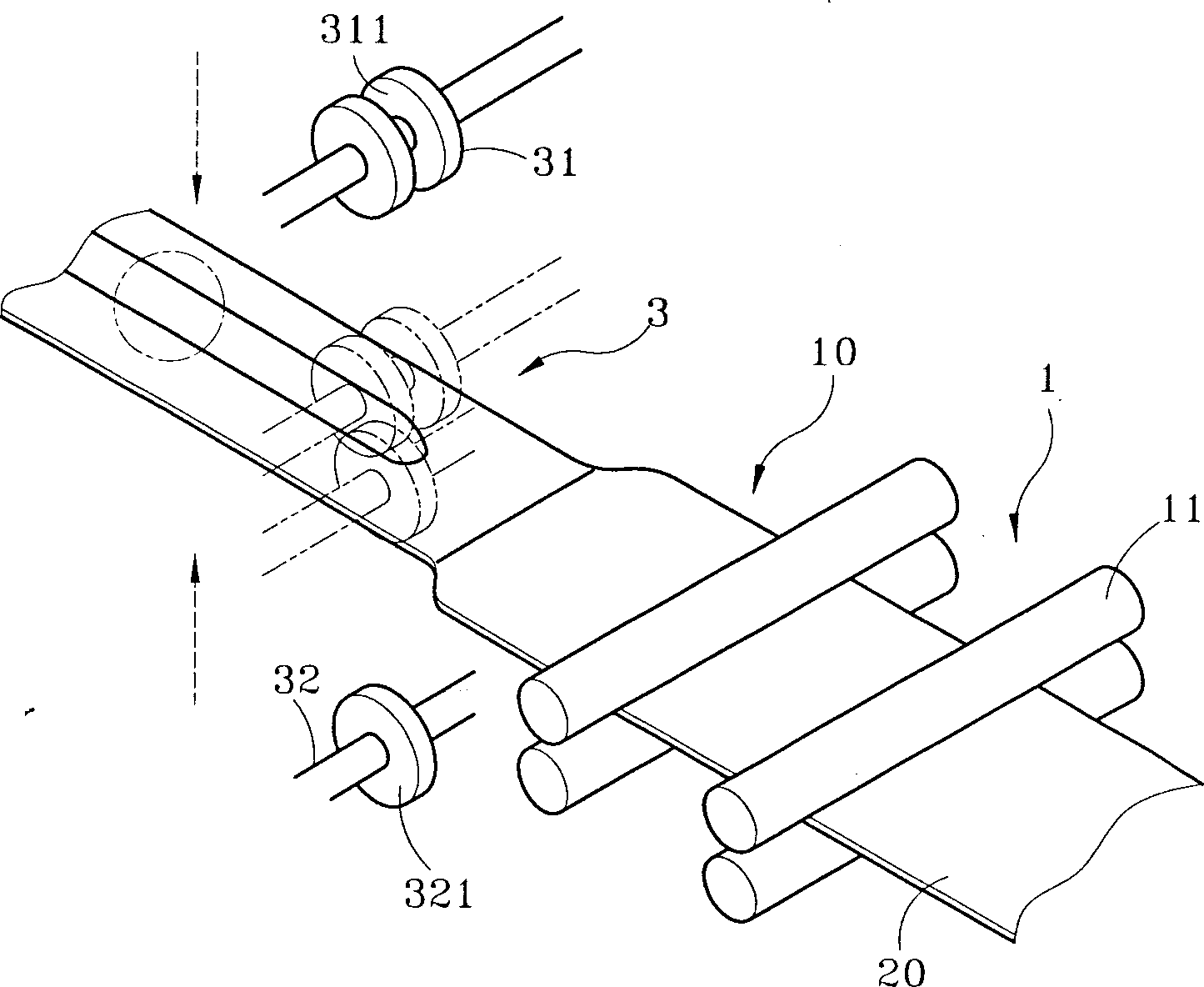

[0028] The manufacturing method of the frame tube body of the chair bearing surface of the present invention includes: a front-stage process 10, a middle-stage process 30 and a rear-stage process 40. Through the three-stage process, a steel plate or other metal sheet 20 can be roll-formed into a usable Tube body on the frame of the load-bearing surface of the chair.

[0029] When the above-mentioned pipe body is manufactured, a steel plate 20 is firstly taken as the pipe body substrate, and in the preceding process 10, the steel plate 20 is first transported on the leveling mechanism 1 (such as figure 1 As shown), the leveling mechanism 1 utilizes a plurality of rolling cylinders 11 to level the surface of the steel plate 20 to eliminate unevenness on the surface of the steel plate 20 and improve the quality of pipe body manufacturing;

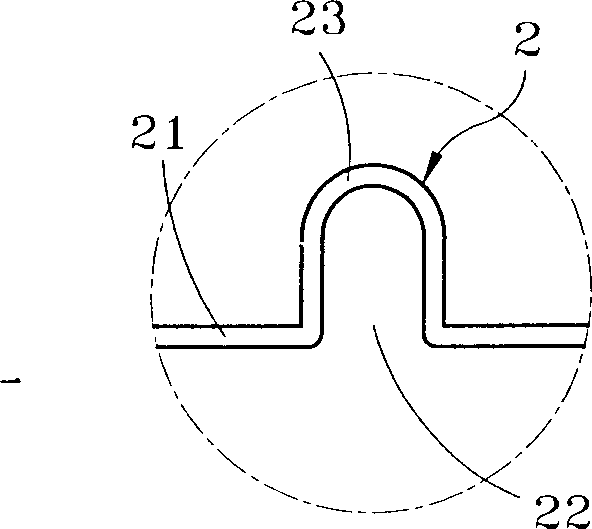

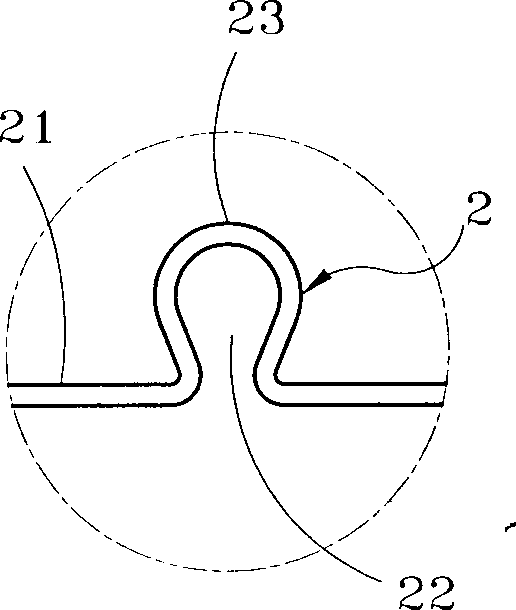

[0030] After the steel plate 20 is leveled by the leveling mechanism 1, after being rolled by the concave surface 311 and the convex surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com