Preparation method for water soluble carbon nanotube

A carbon nanotube, water-soluble technology, applied in the field of preparing water-soluble carbon nanotubes, can solve the problems of limiting the large-scale practical application of carbon nanotubes, destroying the perfect structure of carbon nanotubes, difficult to control the processing process, etc. Industrial application, good water solubility, mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Commercialized carbon nanotubes were refluxed and purified with 2.6mol / L dilute nitric acid for 48 hours, washed with water to neutrality and dried, and then the purified carbon nanotubes obtained were mixed with excess disazo dyes and ground for 2 hours to obtain The mixture of carbon nanotubes and azo dyes can be completely dissolved in water, wherein the excess free azo dyes can be removed by washing with water without reducing the water solubility of carbon nanotubes.

Embodiment 2

[0014] Commercialized carbon nanotubes were refluxed and purified with 2.6mol / L dilute nitric acid for 48 hours, washed with water to neutrality and dried, and the obtained purified carbon nanotubes were mixed with excess disazo dyes, dissolved in an appropriate amount in water, and placed in Sonicate in a high-power sonicator until there is no solid residue, and the excess free azo dye can be removed by washing with water without reducing the water solubility of the carbon nanotubes.

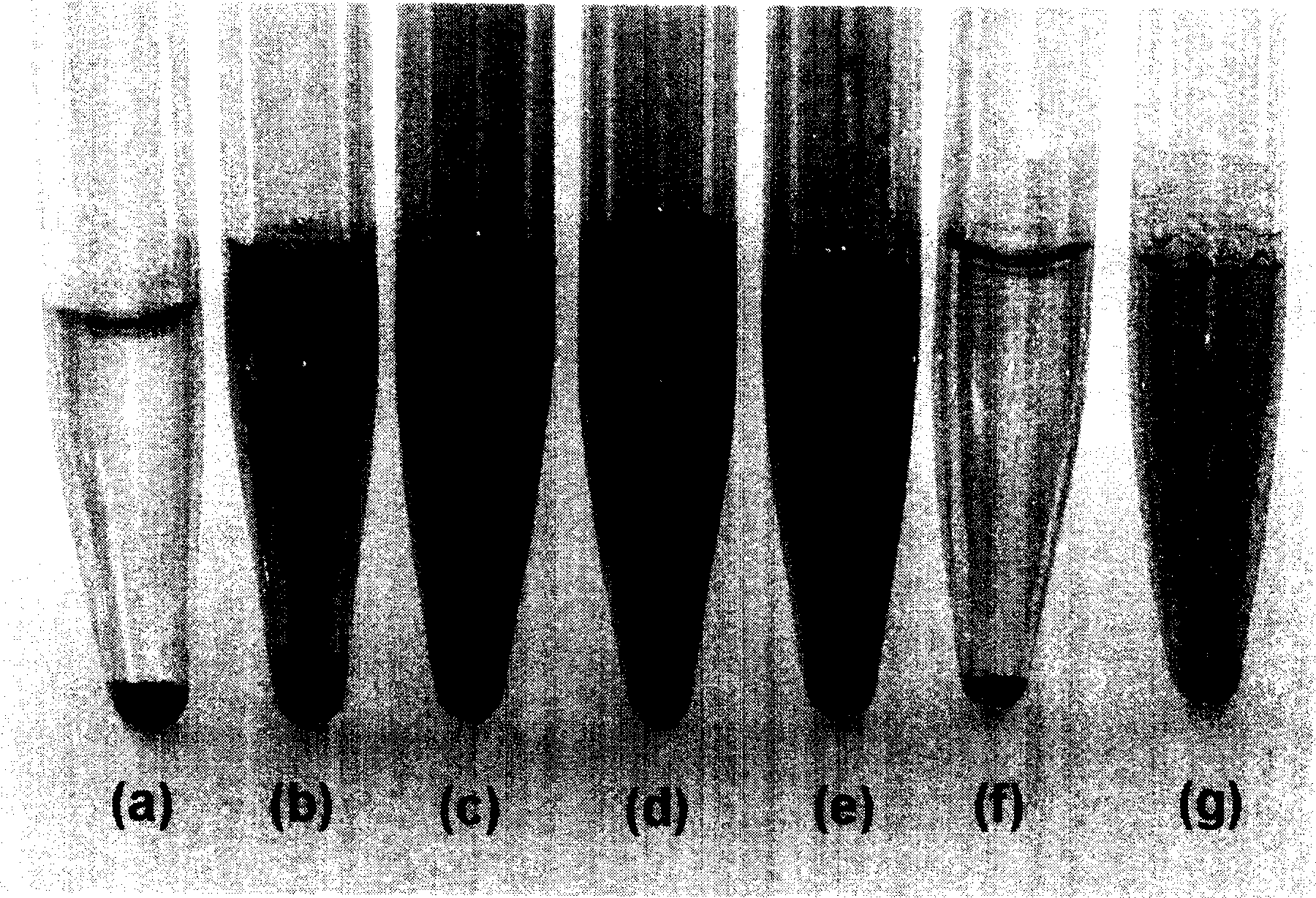

[0015] The excellent solubility in water of the water-soluble carbon nanotubes prepared by non-covalent modification provided by the present invention will be described below with reference to the accompanying drawings. It can be clearly seen from the figure that although the 48-hour reflux purification process of dilute nitric acid, the carbon nanotubes are still completely insoluble in water ((a) in the accompanying drawing); , most of the carbon nanotubes were settled down, and only a small ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com