Process for preparing dimethyl ether

A dimethyl ether and process technology, applied in the field of dimethyl ether production, can solve the problems of high production cost, poor economy, difficulty in adapting to large-scale production, etc., and achieve the effects of improving market competitiveness and reducing production energy consumption and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0014] According to the technological process of the present invention, young bituminous coal is used as raw material, multi-nozzle opposed coal-water slurry pressurized gasification furnace, and the quenching process is used for gas production. The coal slurry concentration is 60%-62% (m); the gasification pressure is 5.5-6.5MPa, and the gasification temperature is 1400-1450°C.

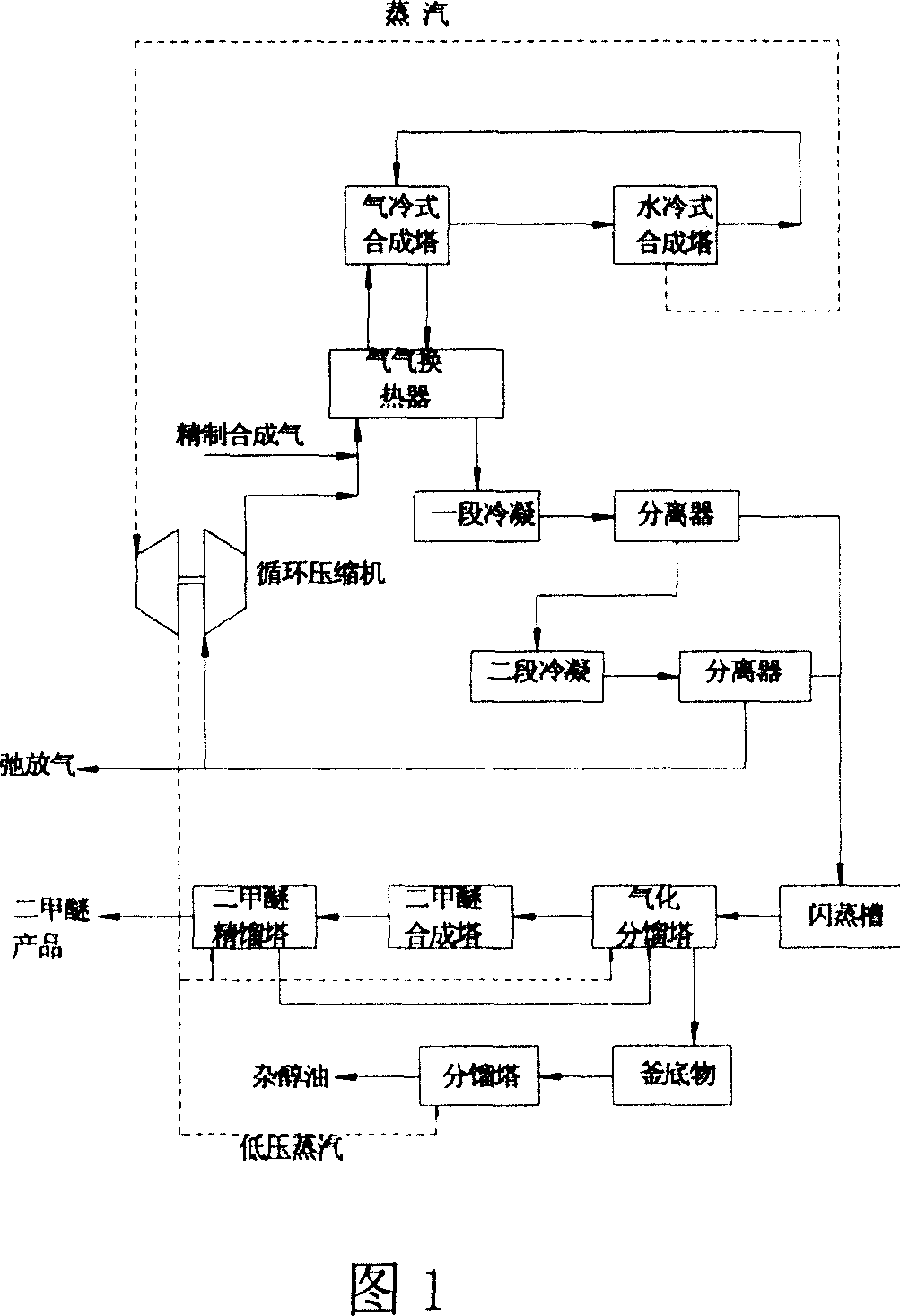

[0015] The crude gas produced by gasification is purified by sulfur-resistant shift, MNHD desulfurization, decarbonization and other purification methods to produce synthesis gas that meets the requirements of methanol synthesis. In an air-cooled-water-cooled combined methanol synthesis reactor, methanol is synthesized under a pressure of 4.5-12.0 MPa. The methanol-containing reaction gas undergoes heat recovery and two-stage condensation cooling. The pressure of the condensation cooling system is 3.5-11.0MPa, and the temperature is 30-120°C. The condensate is separated by flash evaporation to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com