Tumble angle measuring method and measurer

A roll angle measurement and light measurement technology, applied in measurement devices, instruments, optical devices, etc., can solve problems such as measurement nonlinear errors, and achieve the effects of improving adaptability, compact structure, and improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

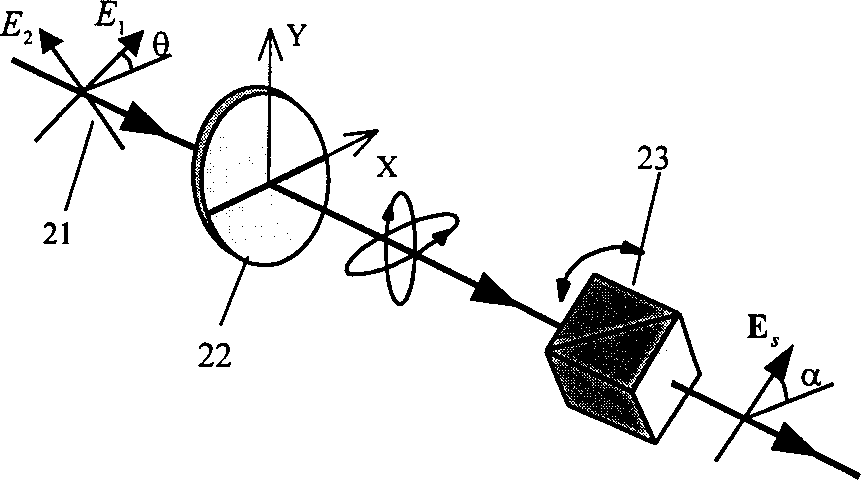

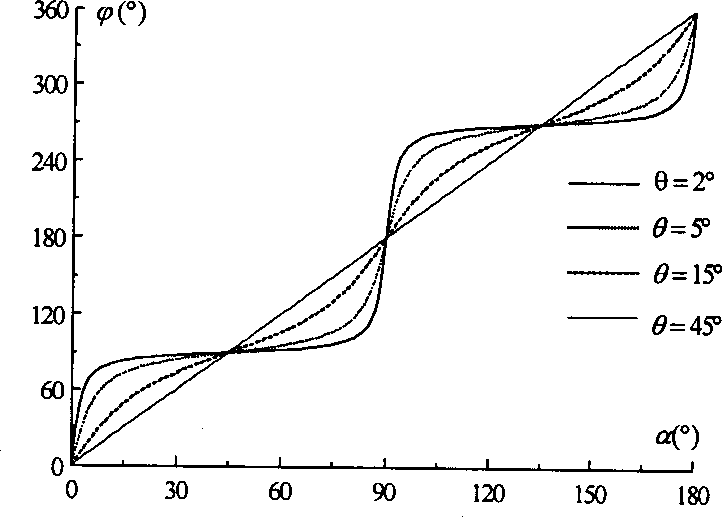

Method used

Image

Examples

Embodiment 1

[0079] Embodiment 1 of the device of the present invention: SGJ-1 type transverse Zeeman dual-frequency laser is adopted, and the frequency stabilization accuracy is 10 -7 , The frequency difference is 269K, the cut-off frequency of the two photodetectors is 2M, the phase meter adopts the Danish phase meter (Phase MeterType: 2997), and the phase measurement accuracy is 0.1 degree. On the basis of the principle of the present invention, the residual ovalization of the transverse Zeeman laser itself is directly used, so the 1 / 4 wave plate can be omitted and the drift link can be reduced. This system could theoretically achieve a multiplication factor of more than 200, and the total sensitivity multiplication factor is currently 110.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com