Bidirectional stress tuner of optical fibre raster

A fiber grating, bidirectional stress technology, applied in the direction of coupling of optical waveguides, can solve the problems of easy bending and deformation of fiber grating, and achieve the effect of uniform stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

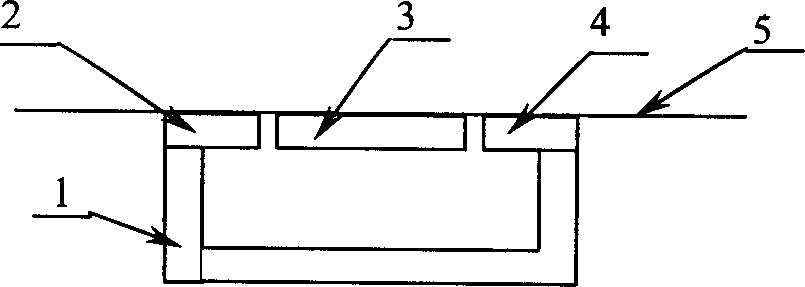

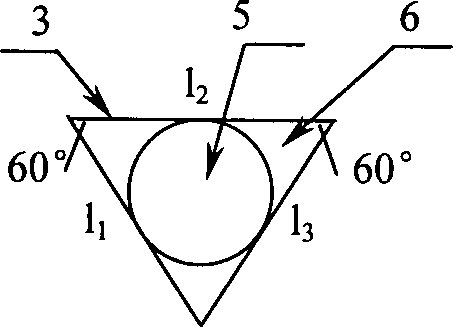

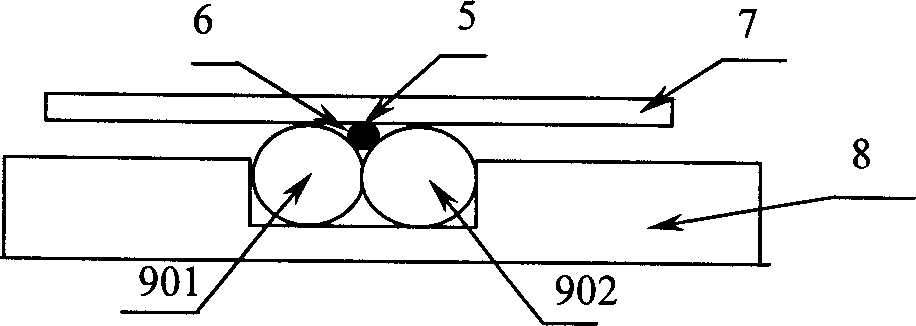

[0039] The structure of forming the inner chamber 6 of the guide rail 3 is as follows: image 3 , 4 , 5, and 6. The driving structure used is 1 such as Figure 7 shown.

[0040] Specific parameters of fiber Bragg grating 5, a uniform fiber Bragg grating with a length of 10mm, its central wavelength is 1551.2nm, and the reflectivity is greater than 90%. The obtained results are as follows Figure 8 , Figure 9 shown.

[0041] Figure 8 It is the tuning spectrum of the tuning device of the present invention when the current in the electromagnetic coil is 300mA. It can be seen from the figure that during the tuning process, the Bragg reflection peak of the fiber grating 5 reaches from position B to position A, and the tuning amount is 1.38nm. It is worth noting that the bandwidth of the reflection spectrum basically does not change, and the channel isolation reaches Above 15dB.

[0042] Figure 9 It is the recovery curve of the tuning device of the present invention. It ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com