Optical information recording medium and its manufacture

A recording medium and laser recording technology, which are applied in the manufacture of optical record carriers, optical record carriers, and recording/reproducing by optical methods, etc., can solve problems such as the reduction of recording characteristics, achieve good recording characteristics, and inhibit the effect of decomposition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

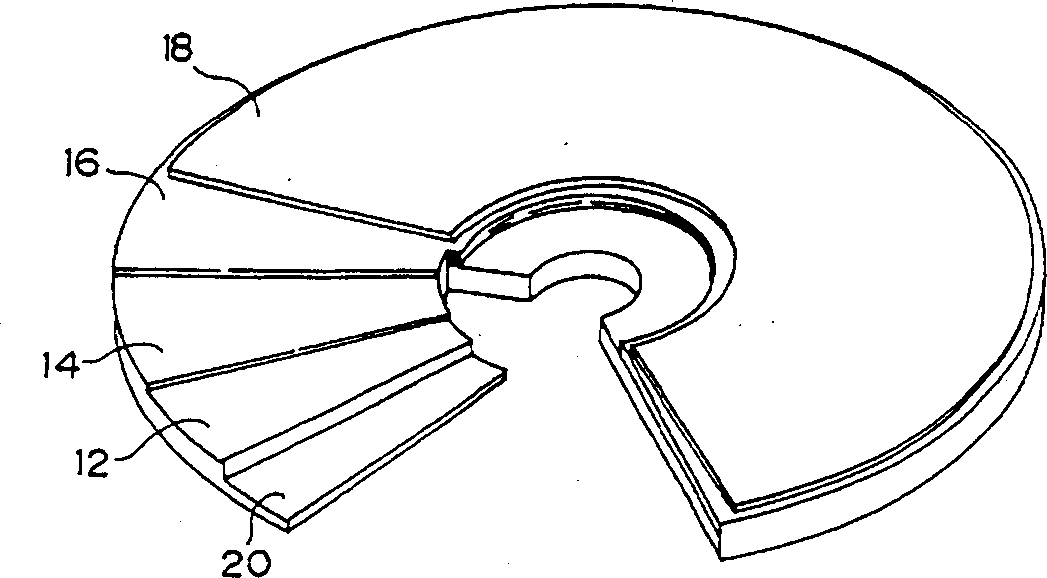

[0056] [Production of CD-R discs]

[0057] Spiral grooves (pitch: 1.6μm 1. Groove width: 0.5 μm, groove depth: 0.18 μm, groove inclination angle: 55°). Figure 6 A schematic cross-sectional view showing the groove shape. As defined in this figure, the depth D of the groove is the distance from the surface of the substrate before the groove is formed to the deepest part of the groove, the width W of the groove is the groove width of D / 2 depth, and the groove width The inclination angle is the angle between the straight line connecting the inclination portion from the surface of the substrate before the formation of the trench to the depth of D / 10 and the inclination portion from the deepest groove to the height of D / 10, and the substrate surface.

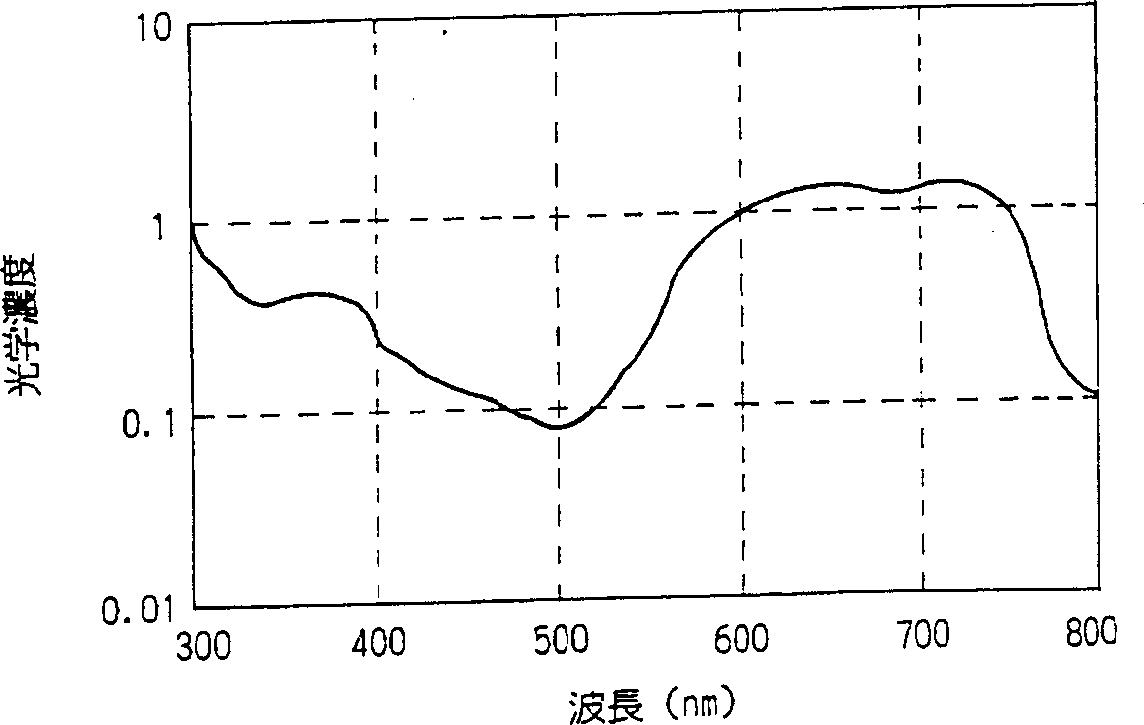

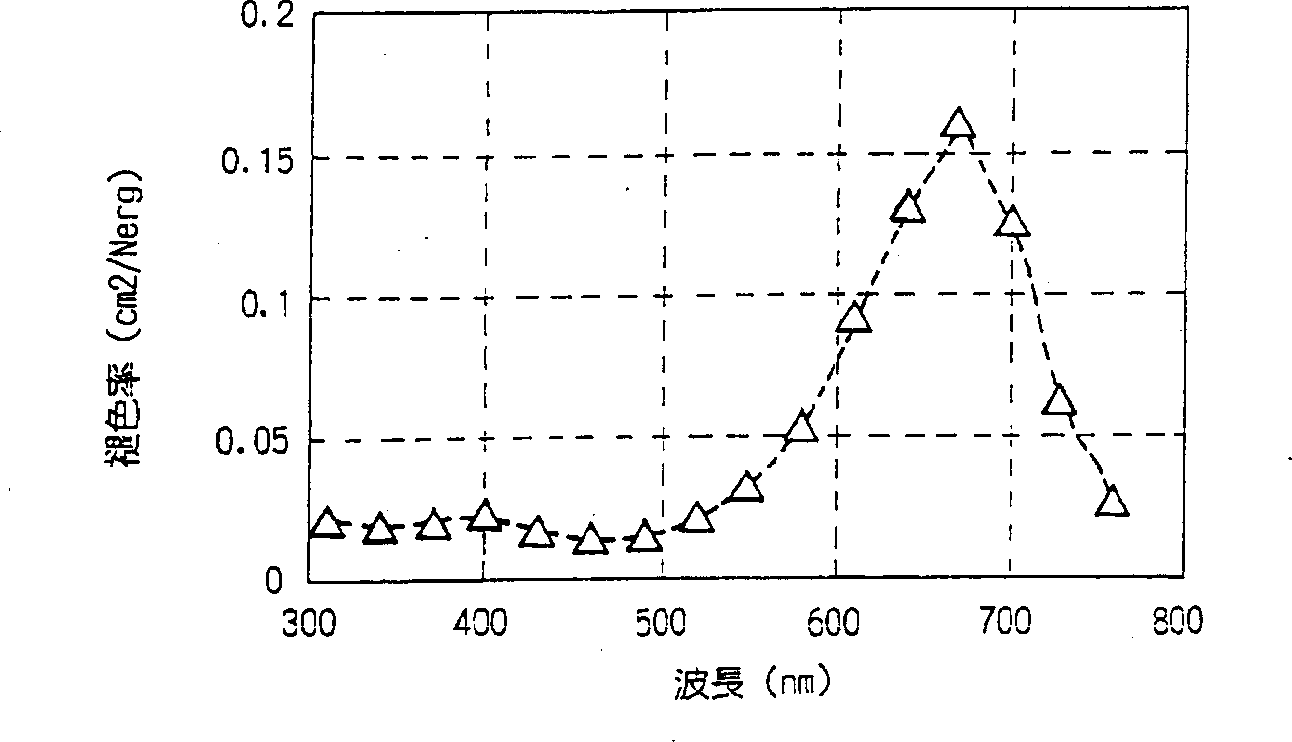

[0058] Next, using an ultrasonic oscillator (1800W), within 1 hour, 2.65g of the above-mentioned cyanine pigment (A) was deeply dissolved in 100ml of 2,2,3,3-tetrafluoropropanol, and prepared to form a recording layer. coating sol...

Embodiment 2

[0066] [Production of short-wavelength discs]

[0067] Spiral grooves (pitch: 0.4μm, Groove width: 0.2 μm, groove depth: 0.08 μm, groove inclination angle: 60°).

[0068] Next, on the groove-side surface of the polycarbonate substrate, Ag was sputtered by DC magnetron sputtering to form a light reflection layer with a thickness of 80 nm.

[0069] Next, 1.5 g of the above dye (B) was dissolved in 100 ml of 2,2,3,3-tetrafluoropropanol within 1 hour using an ultrasonic oscillator (1800 W) to prepare a coating solution for forming a recording layer. Apply the coating liquid on the groove side surface of the polycarbonate substrate on which the light reflection layer is formed by spin coating, prepare 0.5 ml at 300 rpm, change the rotation speed to 300 rpm to 4000 rpm, and dry to form a pigment record layer. The pigment recording layer was formed to a thickness of 100 nm in the groove and to a thickness of 60 nm in the land portion. On the above-mentioned pigment recording laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com