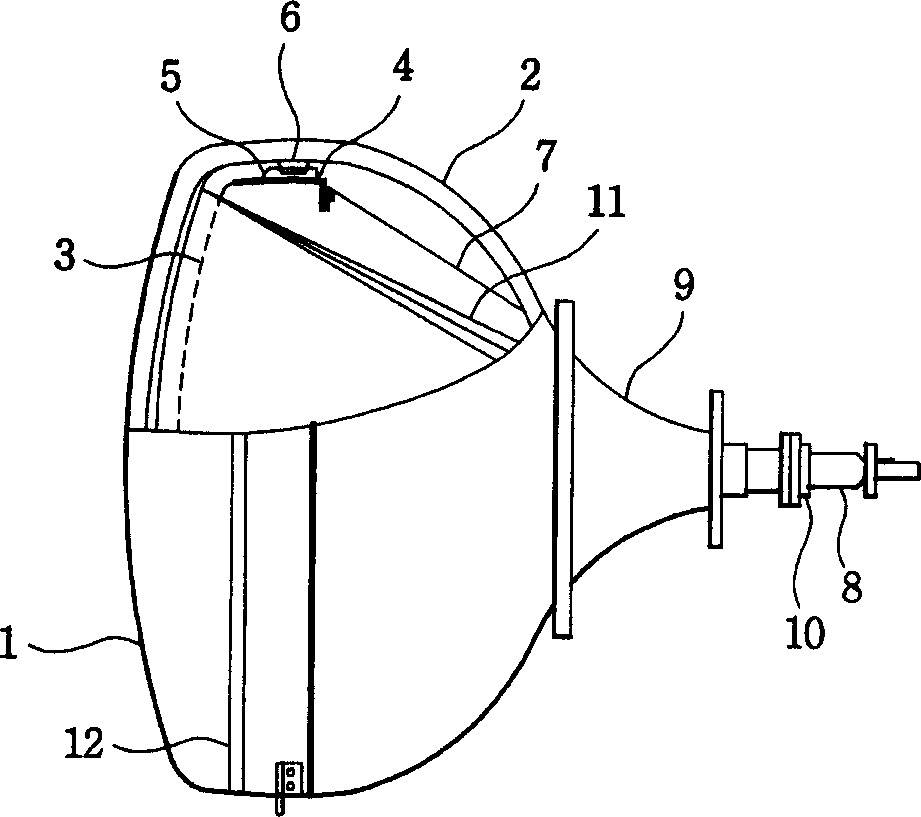

Cathode-ray tube

A cathode ray tube, diagonal technology, applied in the direction of cathode ray tube/electron beam tube, cathode ray/electron beam tube shell/container, discharge tube, etc., can solve the problem of reducing productivity, high investment, increasing product cost, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

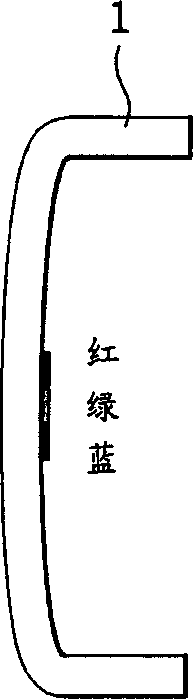

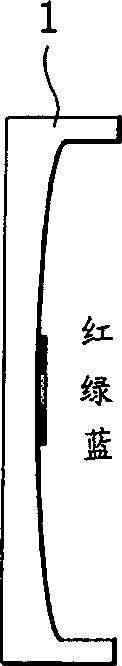

[0019] Hereinafter, preferred embodiments of the present invention shown in the accompanying drawings will be described in detail.

[0020] Based on the fact that the thickness difference caused by its wedge rate causes a considerable irregular temperature distribution in the welding part of the diagonal corner of the panel, the inventors conducted tests according to the temperature change in the welding sealing furnace to find out Key Factors Affecting CRT Recycling. Figure 5 It is a curve representing the furnace process specification in the fusion sealing process. The factors of heating rate, soak time, cooling rate and peak temperature can be found from this curve. Test in the following way: as in image 3 As shown, the products that have passed through the sealed furnace are recovered, and these products pass through the sealed furnace at different specified times. The results are shown in Table 1 below. Among them, the same recovery process was used for all products...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com