Method for treating printing and dyeing wastewater by composite biological enzyme

A technology for compounding biological enzymes and printing and dyeing wastewater, applied in the textile industry wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., to achieve high economic benefits, enhance anti-toxicity and impact resistance, reduce The effect of running costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

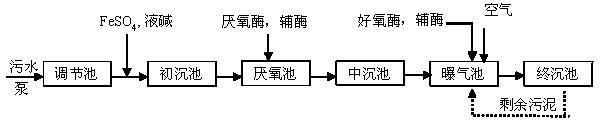

[0021] Please refer to the attached figure 1 Shown, the present invention is a kind of printing and dyeing wastewater treatment method utilizing compound biological enzyme, and it comprises following processing steps:

[0022] 1), pump the printing and dyeing wastewater into the regulating tank, and stay in the regulating tank for 10.5 hours;

[0023] 2), send the sewage into the primary sedimentation tank, and add FeSO 4 and liquid caustic soda, and stay in the primary sedimentation tank for 7.25 hours;

[0024] 3), send the sewage into the anaerobic tank, add anaerobic enzyme and coenzyme, and stay in the anaerobic tank for 14.9 hours; wherein, the anaerobic enzyme is a hydrolytic enzyme, and the coenzyme is a nutrient substance; the temperature of adding the enzyme is 20-40°C;

[0025] 4), send the sewage into the intermediate sedimentation tank, and stay in the intermediate sedimentation tank for 16.56 hours;

[0026] 5), send the sewage into the aeration tank, add aer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com