Electronic component mounting apparatus, and power supply control method executed by electronic component mounting apparatus

A technology for electronic component installation and electronic components, which is applied in the direction of electrical components, electrical components, etc., can solve the problem of increased power consumption of the drive device, and achieve the effect of saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

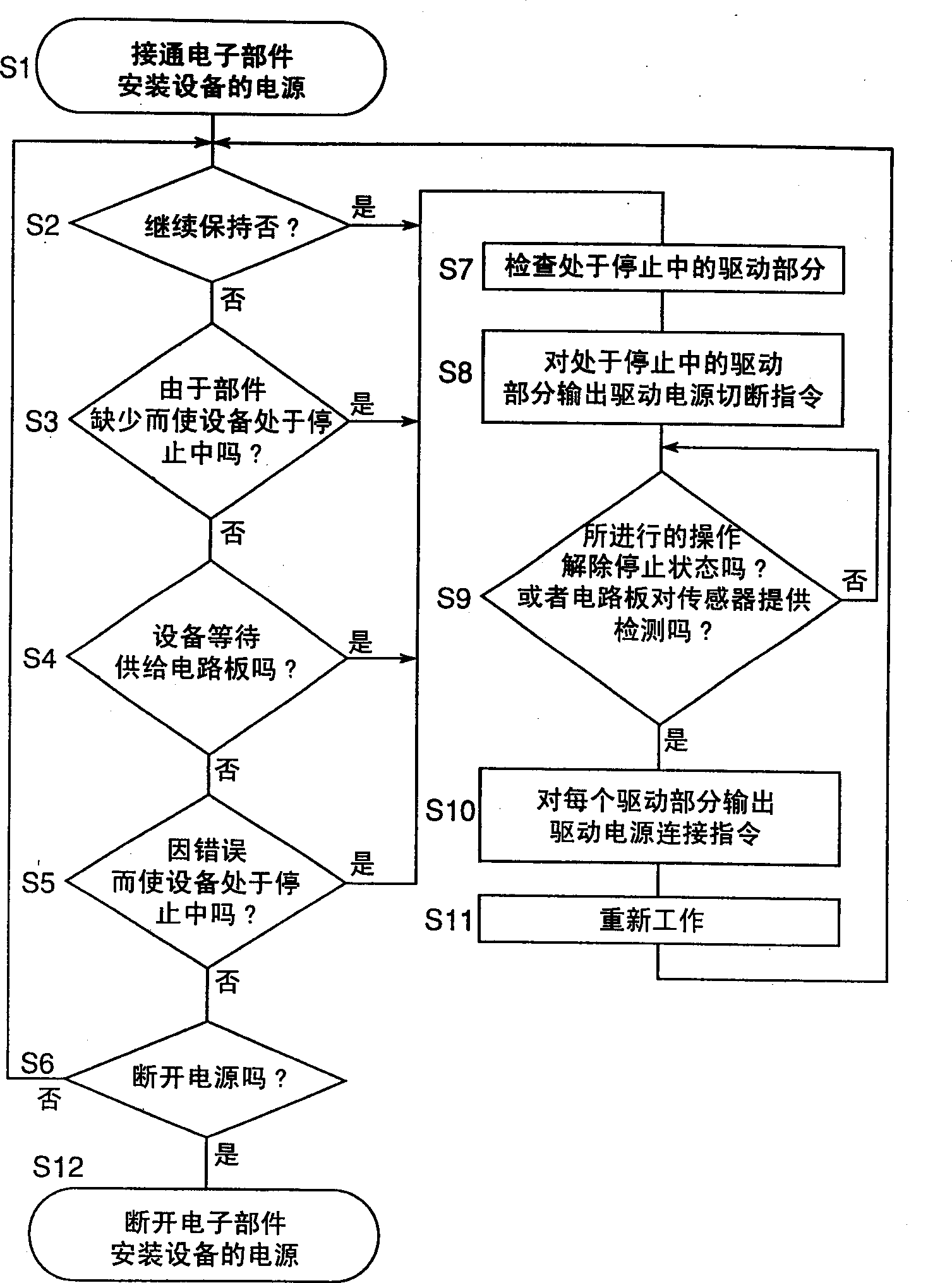

[0028] Hereinafter, an electronic component mounting device of an embodiment of the present invention and a power control method implemented by the electronic component mounting device will be described with reference to the accompanying drawings. The same parts are indicated by the same reference numerals in each figure.

[0029] As an example of the "to be mounted target" described in the above "Summary of the Invention" corresponds to the circuit board in this embodiment. However, the intended installation target is not limited to this, and theoretically includes, for example, a circuit board with liquid crystal display components.

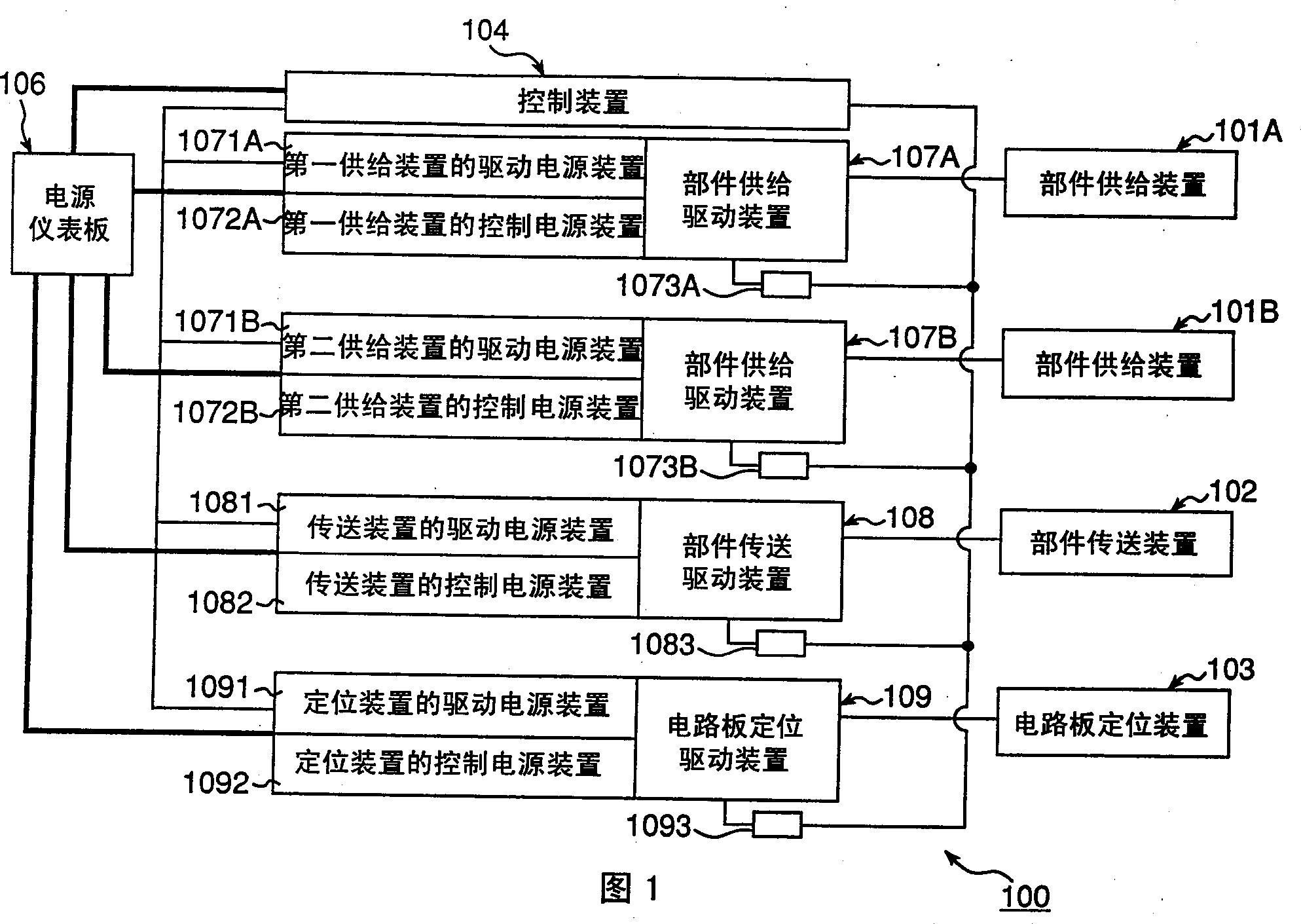

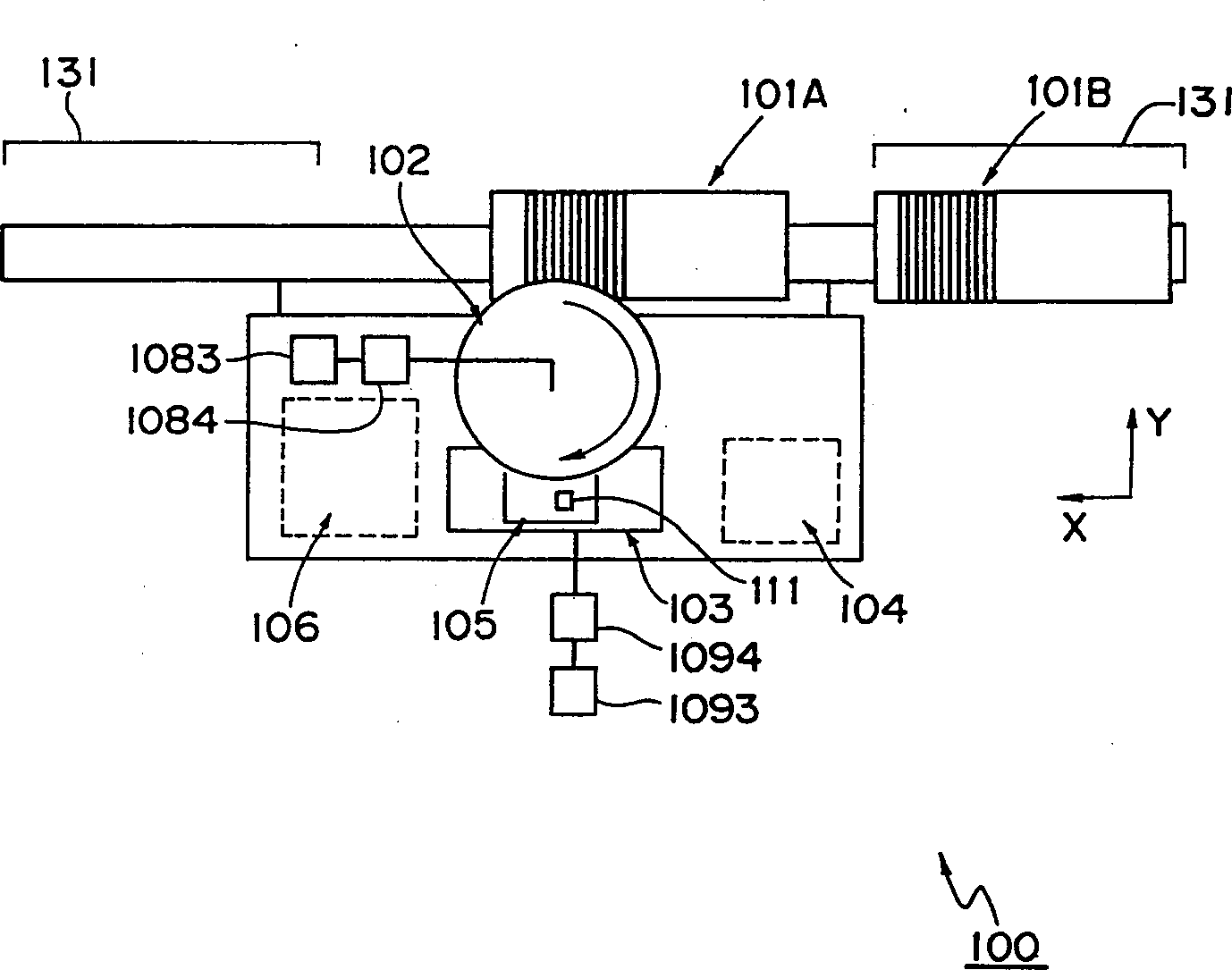

[0030] FIG. 1 shows an electronic component mounting apparatus 100 of this embodiment. The electronic component mounting equipment 100 roughly includes component supply devices 101A and 101B movable in the X direction for supplying electronic components 111 to be mounted on the circuit board 105; and a rotating component transport device 102 for ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com