Production process of dry bamboo shoots in brine

A technology of dried bamboo shoots and salt water, which is applied in the field of preparation of dried bamboo shoots in salt water, and can solve problems such as poor penetration of seasoning liquid and loss of resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

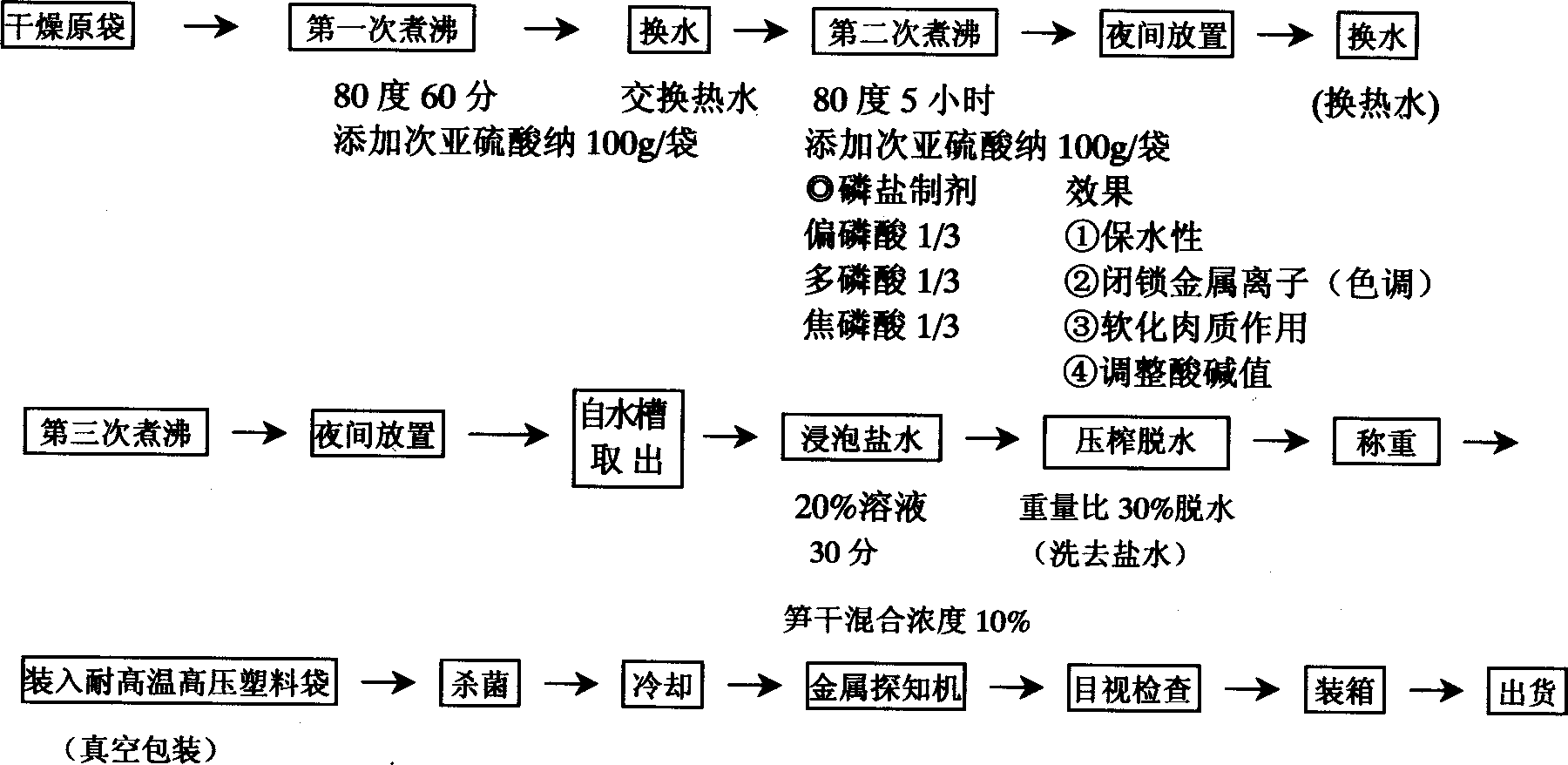

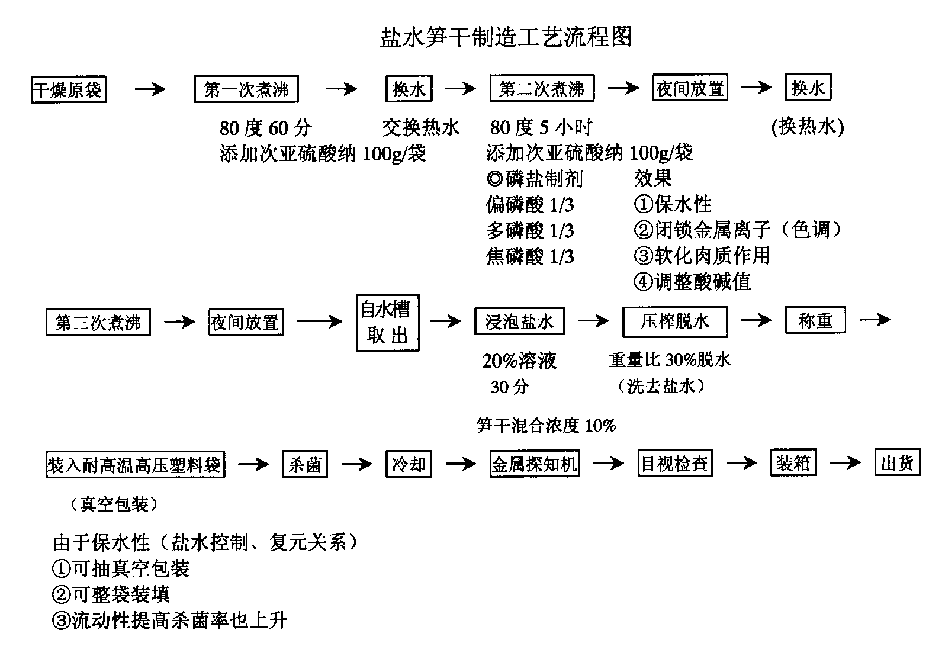

[0014] Get 30kg of dried bamboo shoots with a moisture content of 20% (weight ratio), soak them in 80-degree hot water adding 100g of sodium hyposulfite and boil for 60 minutes, then change the water, soak the dried bamboo shoots after the water change in 80-degree hot water, Add 100g of sodium hyposulfite, metaphosphoric acid, polyphosphoric acid, and pyrophosphoric acid in a ratio of 1:1:1 to prepare a compound phosphate preparation, boil for 5 hours and then leave it overnight, then change the water, and then soak the aforementioned dried bamboo shoots in 80°C hot water Boil in medium, let stand overnight and remove from sink. Adding preparations such as sodium hyposulfite and phosphate in the rehydration process has good effects on water retention, color stability, meat softening and acid-base adjustment of dried bamboo shoots. Soak the dried bamboo shoots through the rehydration program in a salt solution with a concentration of 20% (weight ratio) for 30 minutes, squeeze ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com