Method for creasing a packaging laminate, a packaging laminate and a packaging

A stacking and bending technology, applied in packaging, wrapping paper, transportation and packaging, etc., can solve problems such as no description of bending methods, and achieve the effect of cheap methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

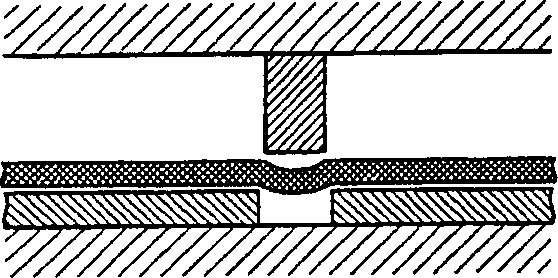

[0039] Figure 1A -D shows a traditional packaging stack bent by a traditional bending method, the cardboard stack is bent on the die by bending the scoreboard ( Figure 1A ), according to the problem of the prior art described above: the permanent deformation of the convex plane after the traditional bending ( Figure 1B ), the formation of bulges / layers on the fold line ( Figure 1C ), and a permanent increase in thickness at the fold up to 180° ( Figure 1D ).

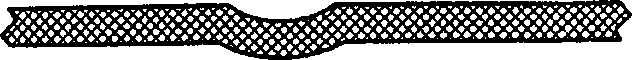

[0040] figure 2 Shown is the initiation of compression cracking on the side plies subjected to compressive loading in a conventional bend. So, according to Figure 1C , the compression crack will grow until the raised part is formed.

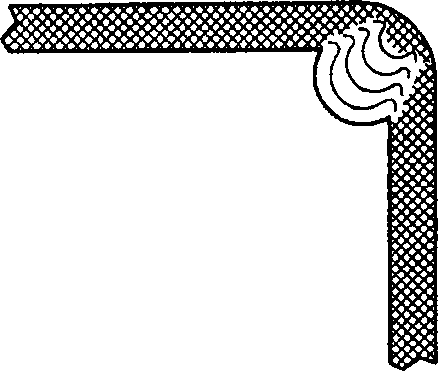

[0041] exist image 3 In , the bending method according to the invention for a packaging stack is shown. The stack comprises a body promoting layer 1 , a side layer 2b on the first side of the stack and two side layers 2a, 3 on the second side of the stack. In the embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com