Surface treating method for panel of image display and display thereof

An image display device and surface treatment technology, applied in the general technology of discharge tube, discharge tube coating, cathode ray/electron beam tube shell/container, etc., can solve the problem of large coating amount, poor material utilization rate, and number of processes Increase and other problems, achieve high clarity and contrast, suppress uneven coating, reduce unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

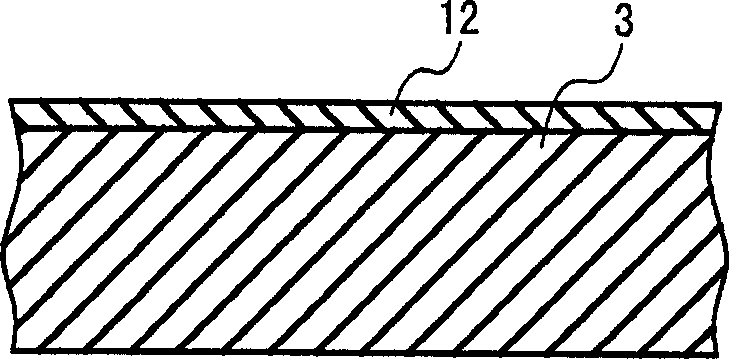

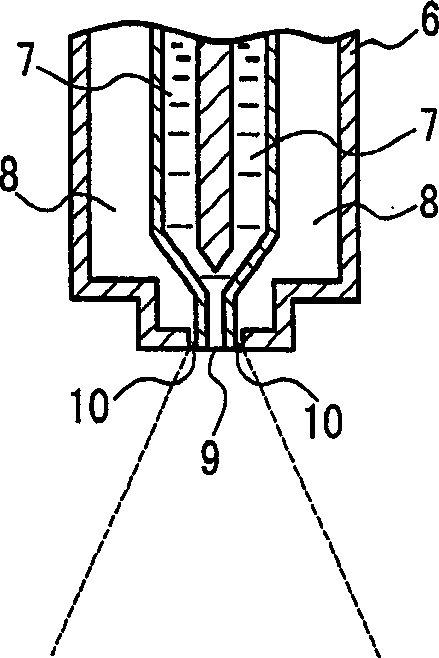

[0049] In order to investigate the effect of this example, a film was formed on the outer surface of the panel portion of the panel using various paints, and the degree of shading of the finished film was compared for each paint. The coating conditions are that the temperature of the panel is 65°C, the spray pressure when the paint is sprayed from the nozzle is 0.4MPa, the discharge rate of the paint is 10ml / min, the distance between the panel and the nozzle is 200mm, and the scanning speed of the nozzle is 300mm / s. The nozzle scanning pitch is 12.5mm. The ambient atmosphere during coating was room temperature 22°C and humidity 56%. The nozzle used here had a ring-shaped air outlet with an outer diameter of 2.4 mm and an inner diameter of 1.5 mm around a circular paint outlet with a diameter of 0.5 mm.

[0050] For ethylene glycol, propylene glycol ether, and water that affect the surface smoothness of the film, in order to confirm the difference based on the effect of their r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap