Composite thin-wall aluminium foil hose

A technology of compounding aluminum foil and hose, which is applied in the direction of hose, pipe, pipe/pipe joint/pipe fitting, etc., can solve the problems of welding seam on the surface of the pipe body, beautiful appearance, complicated production process, etc. Good effect and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

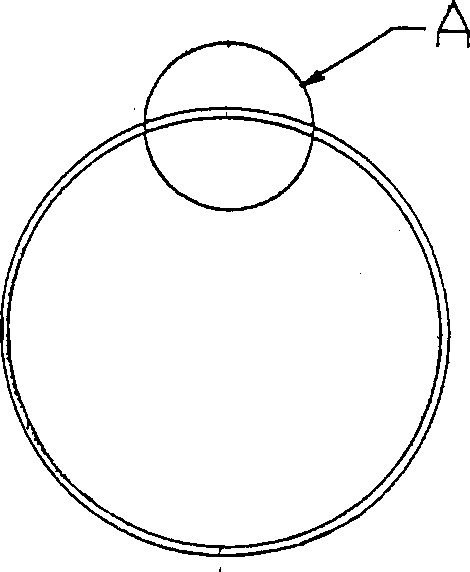

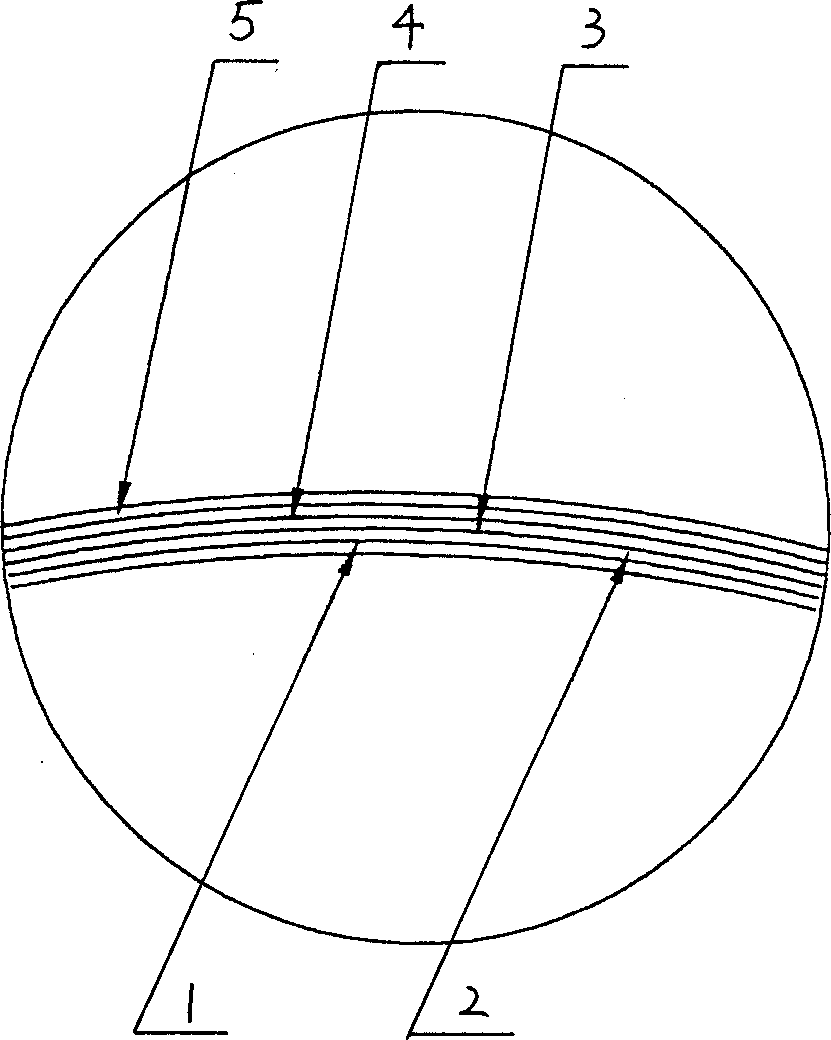

[0020] Such as Figure 7 , Figure 8 and Figure 9 As shown, the composite aluminum foil hose of this embodiment is cylindrical, and its tube body is composed of a composite aluminum foil inner layer 10, an adhesive layer 11 and a plastic outer layer 12 from the inside to the outside, and the composite aluminum foil inner layer 10 is a roll welding structure , there is a section of overlapping area at the intersection of its cylinder joints, the inner layer 10 of the composite aluminum foil in this embodiment is a three-layer composite film, which is composed of pure aluminum foil, adhesive and a layer of polyethylene from the inside to the outside. The middle layer of the pipe body is the bonding layer 11, which is located between the composite aluminum foil inner layer 10 and the plastic outer layer 12. The bonding layer 11 and the plastic outer layer 12 are co-extruded, and the plastic outer layer 12 is composed of five layers of polyethylene. Due to the co-extrusion stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com