Reversible information display medium of liquid crystal type and non-Contact IC card using same

A technology of information display and liquid crystal, applied in liquid crystal materials, static indicators, nonlinear optics, etc., can solve the problems of reducing contrast and contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

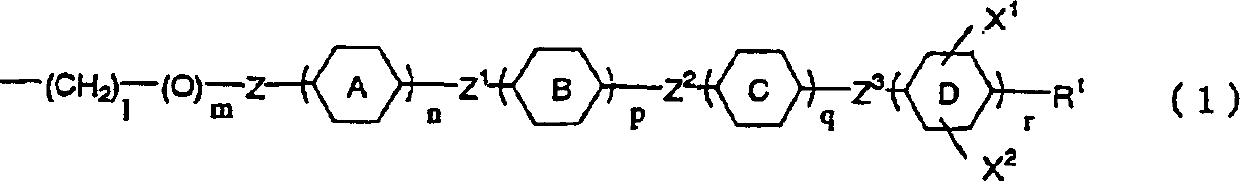

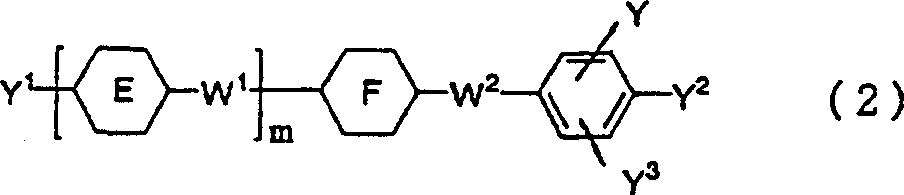

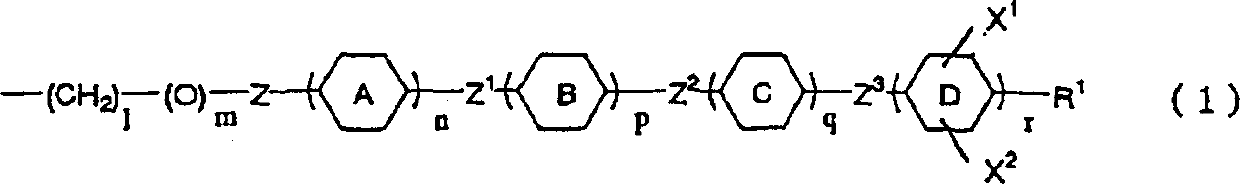

Method used

Image

Examples

Embodiment 1

[0088] In 240 parts by weight of tetrahydrofuran (THF), 100 parts by weight of polymer liquid crystal LCP 105 manufactured by Merck Co., Ltd. and 3 parts by weight of dichroic dye NKX-1366 manufactured by Nippon Photochrome Co., Ltd. were mixed to prepare a liquid crystal recording layer coating liquid. On a polyethylene terephthalate (PET) film on which an Al layer was formed, this solution was applied with a bar coater so that the film thickness after drying was 5 mm. On this film, 50% by weight of a mixture of 100 parts by weight of UV-curable resin NK-OLIGO U-6HA manufactured by Shin-Nakamura Chemical Co. Ethanol solution to make a 2.5mm thick film after ultraviolet irradiation as a protective layer.

[0089]The above-mentioned information recording medium was heated to 130°C, and heat and an electric field were applied under the conditions of 50 Hz and 100 V using the electric field application plate shown in Fig. 6, and the display part became colorless. The reflection ...

Embodiment 2

[0090] In 240 parts by weight of tetrahydrofuran (THF), 100 parts by weight of polymer liquid crystal LCP 105 manufactured by Merck Co., Ltd. and 3 parts by weight of dichroic dye NKX-1366 manufactured by Nippon Photochrome Co., Ltd. were mixed. 10, 20, 30, and 40% by weight of low-molecular liquid crystal ZLI-4792 manufactured by Merck Corporation were added to prepare four types of liquid crystal recording layer coating liquids. These coating liquids were coated with a bar coater on a polyethylene terephthalate (PET) film on which an Al layer was formed so that the film thickness after drying was 5 mm. ULS-1935LH was coated on this film with a bar coater, and after drying, it became a film of 1.5 mm. On this film, 50% by weight of a mixture of 100 parts by weight of UV-curable resin NK-OLIGO U-6HA manufactured by Shin-Nakamura Chemical Co. Ethanol solution, UV irradiation to form a 2.5mm thick film as a protective layer.

[0091] When the information recording medium prepa...

Embodiment 3

[0092] In 240 parts by weight of tetrahydrofuran (THF), 100 parts by weight of high-molecular liquid crystal LCP 105 manufactured by Merck, 25 parts by weight of low-molecular liquid crystal ZLI-4792 manufactured by Merck, and 3 parts by weight of dichroic dye manufactured by Nippon Photochrome Co., Ltd. were mixed. In the coating liquid of NKX-1366, add the UV-curable resin NK ester A-TMM-3 of Shin-Nakamura Chemical Co., Ltd. and the initiator i.e. イルガキユア 907 (mixing ratio, resin / initiator=95 weight) manufactured by Ciba-Geigy Co. parts / 5 parts by weight), so that relative to the sum of high-molecular liquid crystals and low-molecular liquid crystals, they were 10, 20, 30, 40, and 50%, respectively, and five liquid crystal recording layer coating liquids were prepared. These coating liquids were coated on a polyethylene terephthalate (PET) film having an Al layer thereon with a bar coater, dried, and irradiated with ultraviolet rays to form a film with a thickness of 5 mm. UL...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com