Vortex compressor

A scroll compressor and volute technology, applied in the field of scroll compressors, can solve problems such as decline, increase, and leakage of scroll compressor compression efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

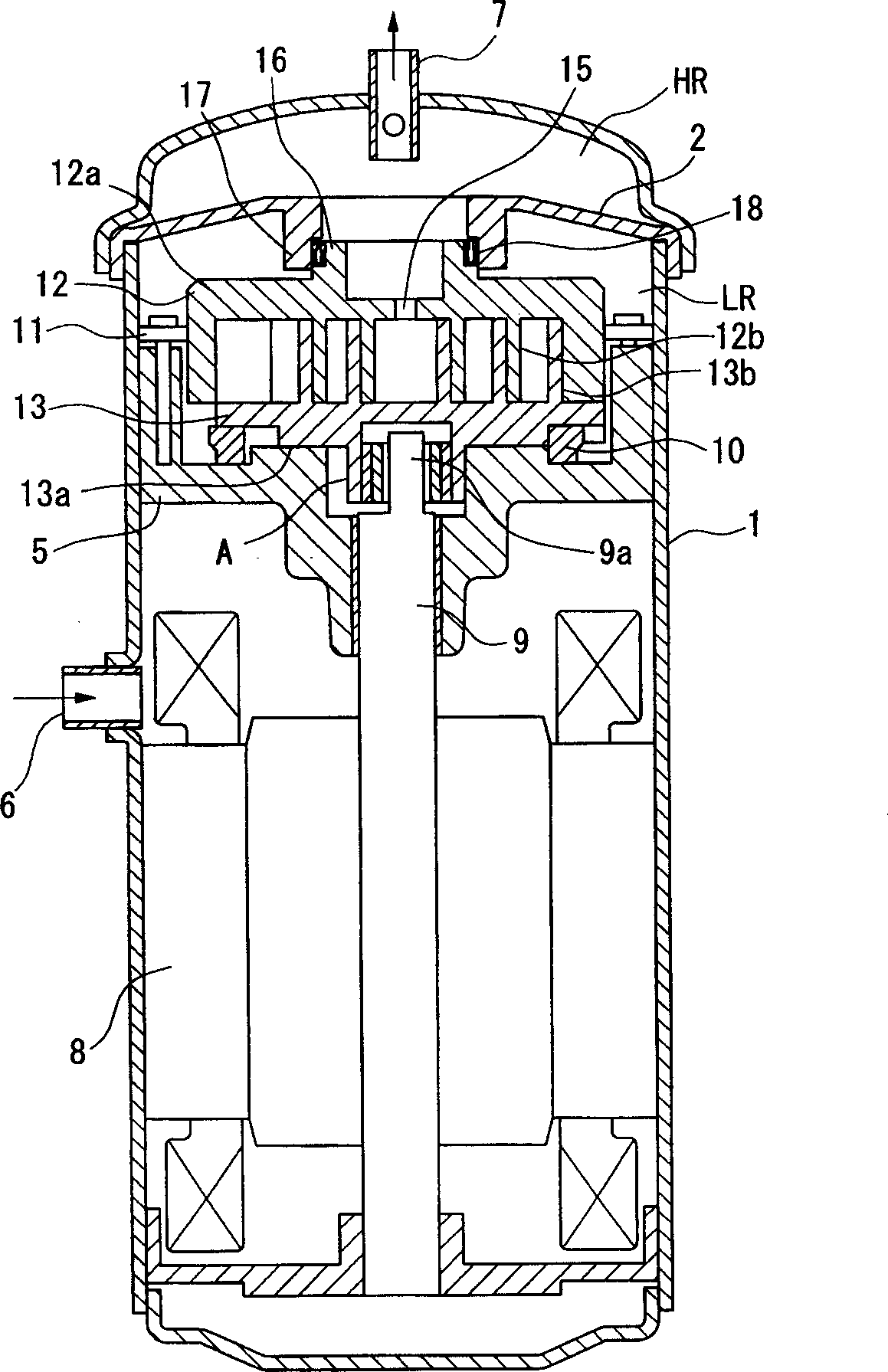

[0032] Refer to attached figure 1 Through 8, an embodiment of the scroll compressor according to the present invention will be explained.

[0033] figure 1 The structure of a back pressure scroll compressor as an embodiment of the present invention is shown. The scroll compressor includes an airtight casing 1, a discharge cover 2 that separates the casing 1 into a high-pressure chamber (HR) and a low-pressure chamber (LR), a frame 5, a suction pipe 6, a discharge pipe 7, a motor 8, and a rotating shaft 9 And anti-rotation mechanism 10.

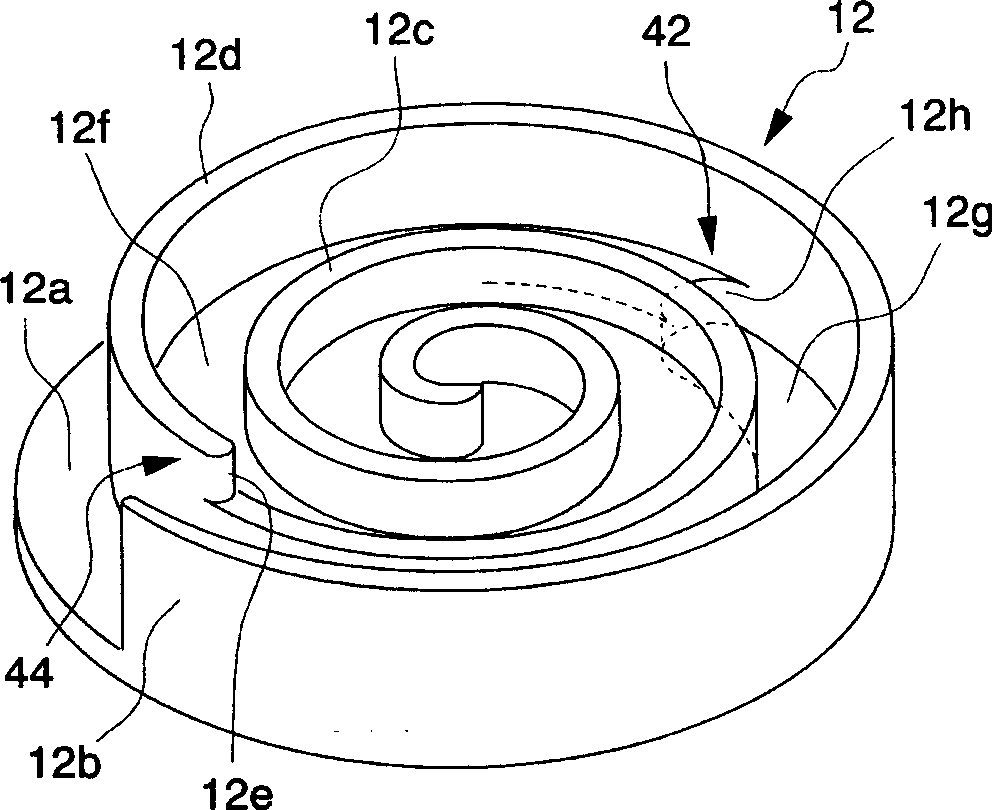

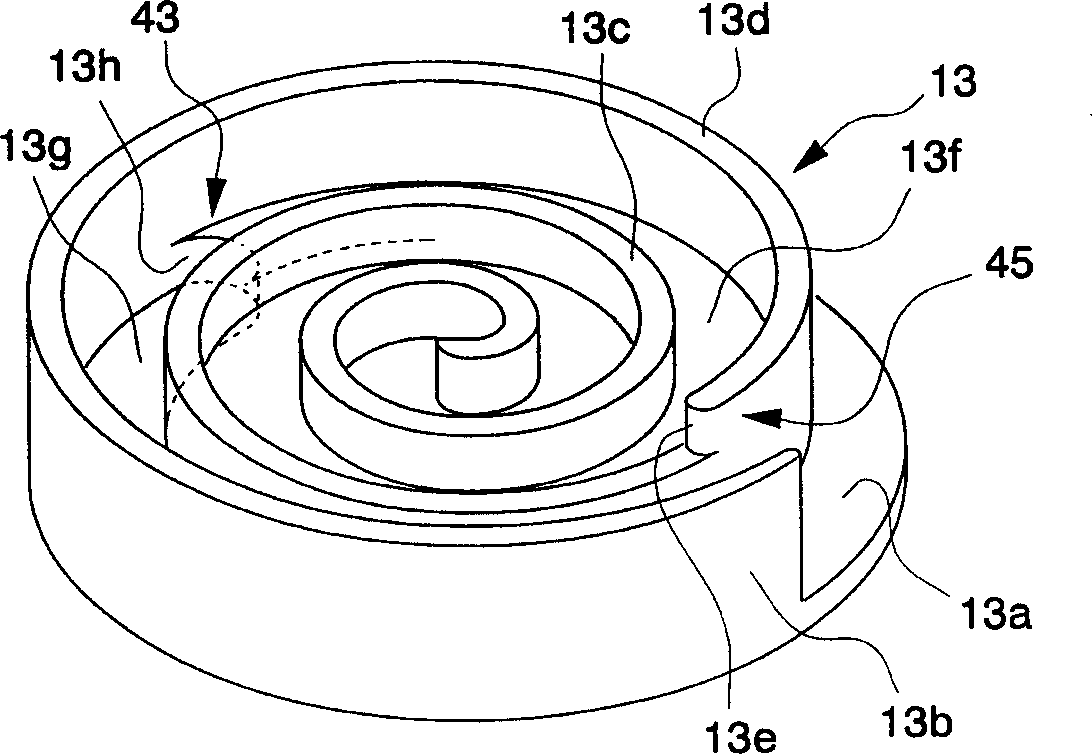

[0034] In addition, the scroll compressor has a fixed scroll 12 and a surrounding scroll 13 engaged with the fixed scroll 12 . Such as figure 2 As shown, the fixed volute 12 includes a spiral wall 12b disposed on the side surface of the end plate 12a. The surrounding volute 13 also includes a spiral wall 13 b disposed on the side surface of the end plate 13 a , especially, the shape of the wall 13 b is similar to that of the wall 12 b ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com