Spin forming method and its equipment

A spinning forming and homogenizing technology, applied in the field of spinning forming methods and devices, can solve the problems of increasing production workers, production equipment and production sites, increasing production costs, increasing scrap rate, etc., so as to improve product quality and production efficiency. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

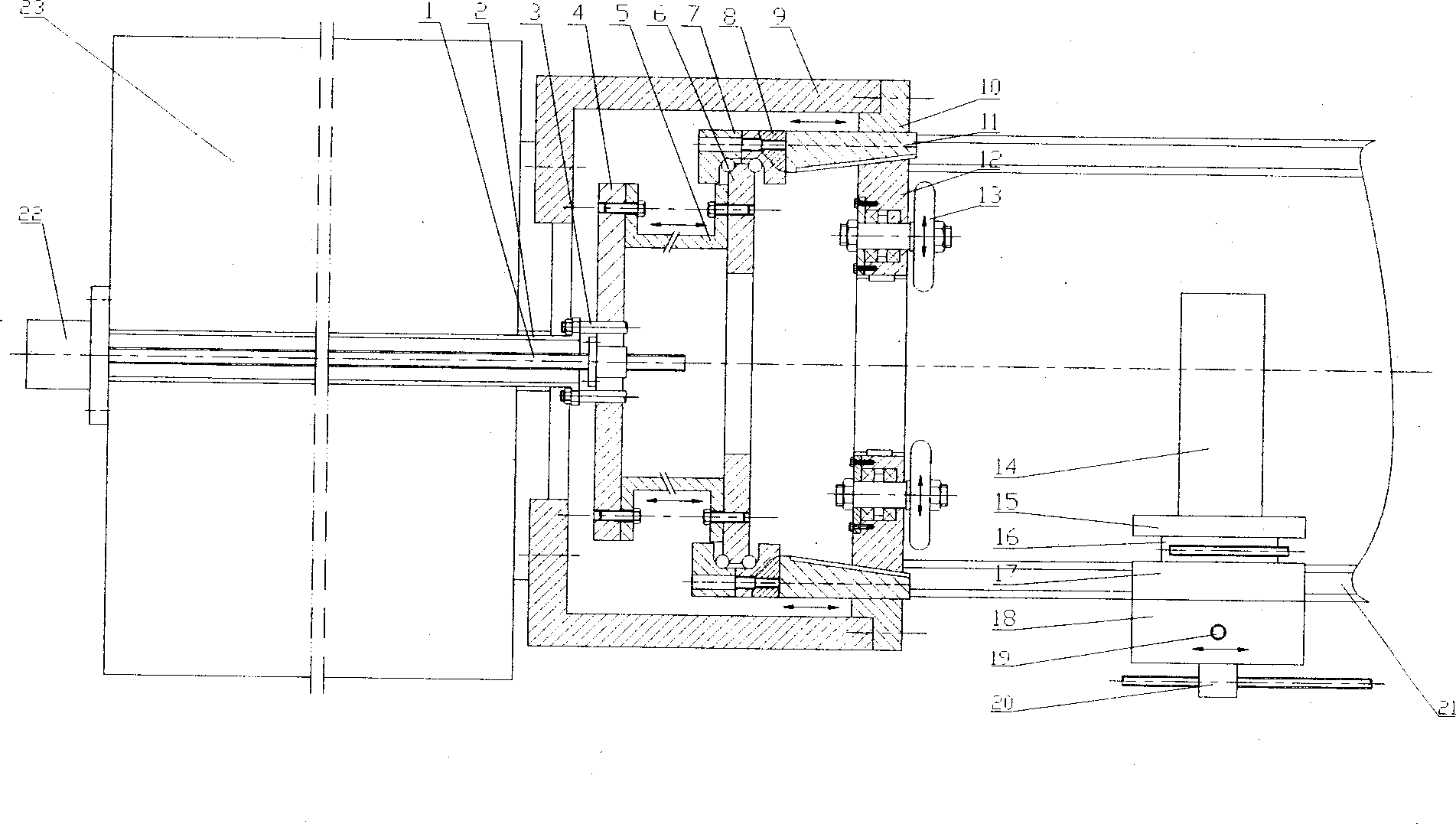

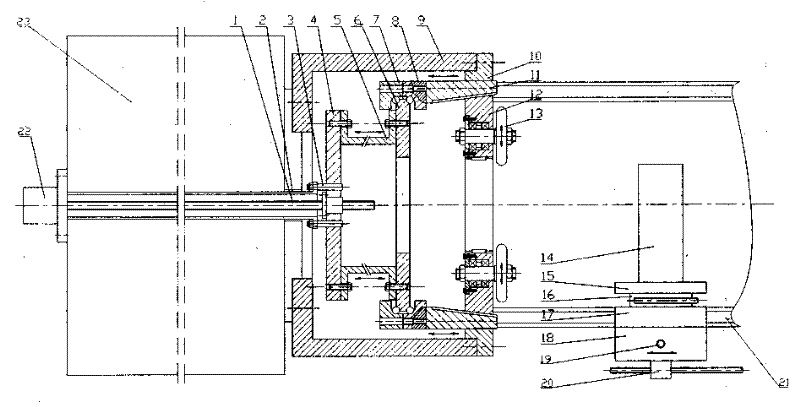

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0015] Such as figure 1 As shown, the axial feed mechanism 1 adopts a feed screw pair. On the one hand, the connection plate 4 is integrated with the axial feed mechanism 1, and is driven by the motor 22 to move in the axial direction; 5 is integrated with the feed plate 6, the left end of the anti-rotation pipe 2 is fixed on the head box 23 of the machine tool, and the four anti-rotation rods 3 on the right end are slidably matched with the connection plate 4, so that the connection plate 4 cannot rotate and can only be rotated along the axis. and drive the feed plate 6 for axial linear feed. The feed ring is divided into two parts, left and right. Connection, the axial slider 11 is designed to be wedge-shaped, and its end is connected to the right feed ring 8, and rolls around the feed disc 6, and simultaneously makes a linear feed motion a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com