Wall of foam EPS bricks filled in metallic net

A metal mesh and brick wall technology, applied in the field of building materials, can solve problems such as inseparability, and achieve the effects of low cost, simple construction, and uncomplicated processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

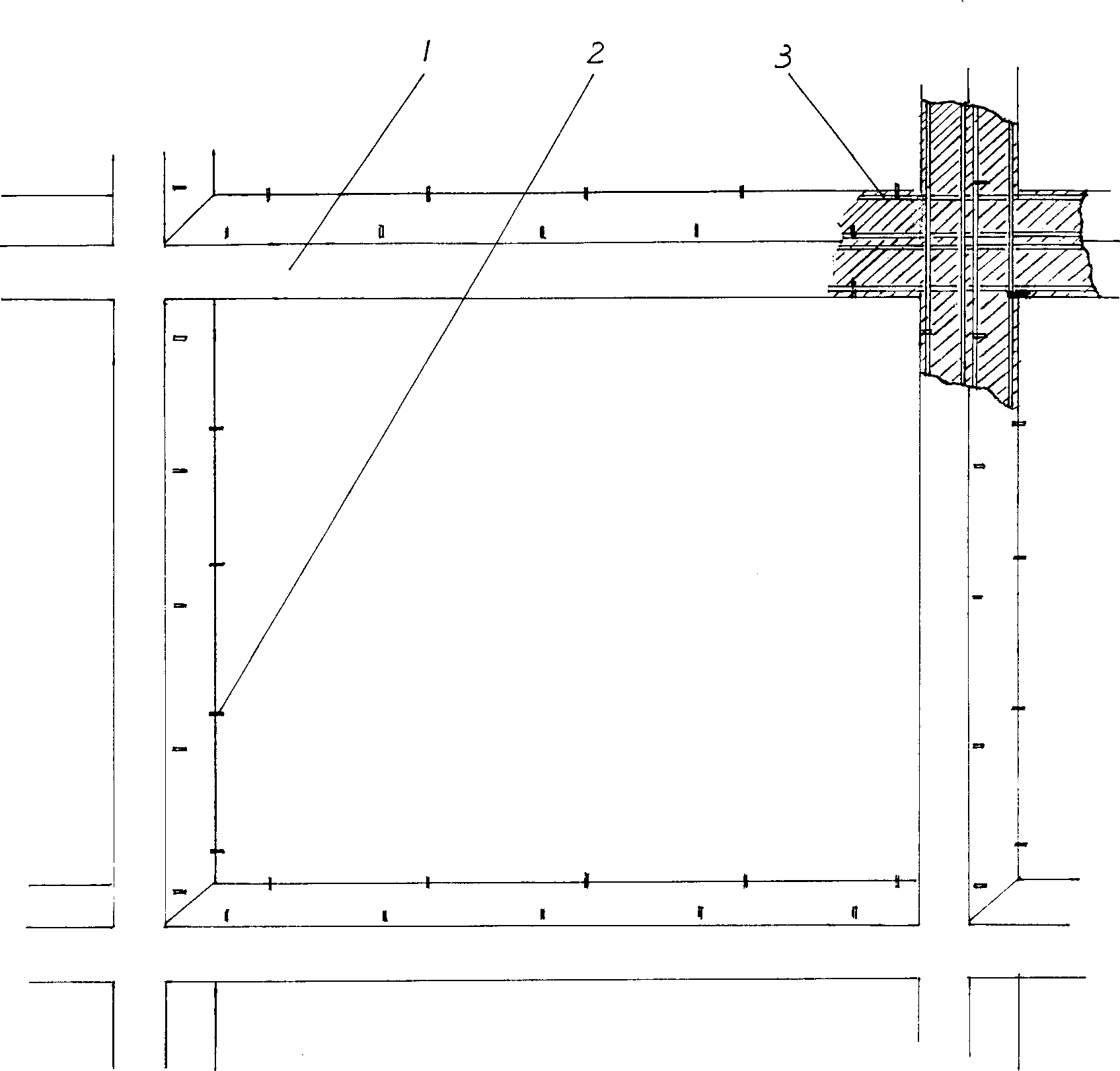

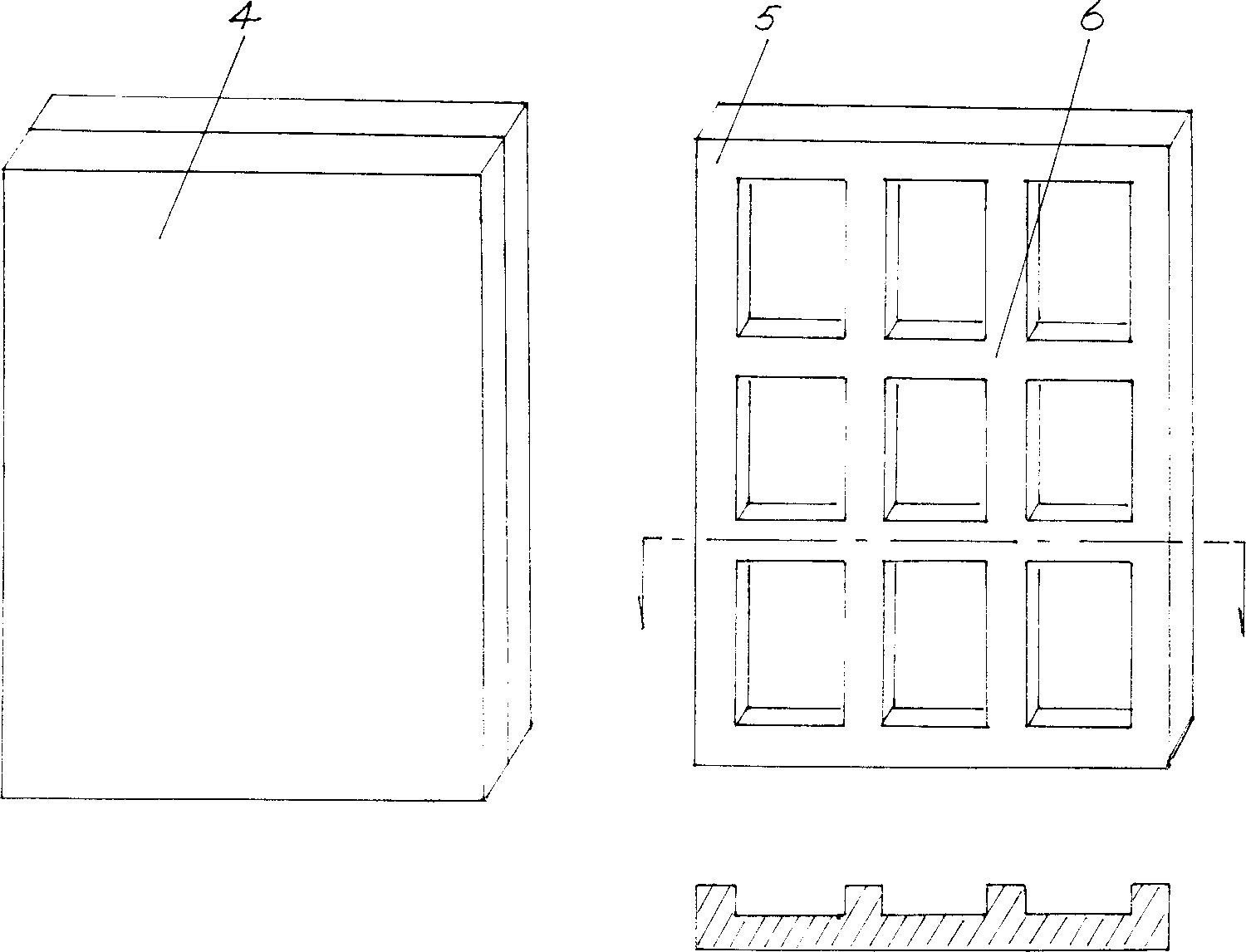

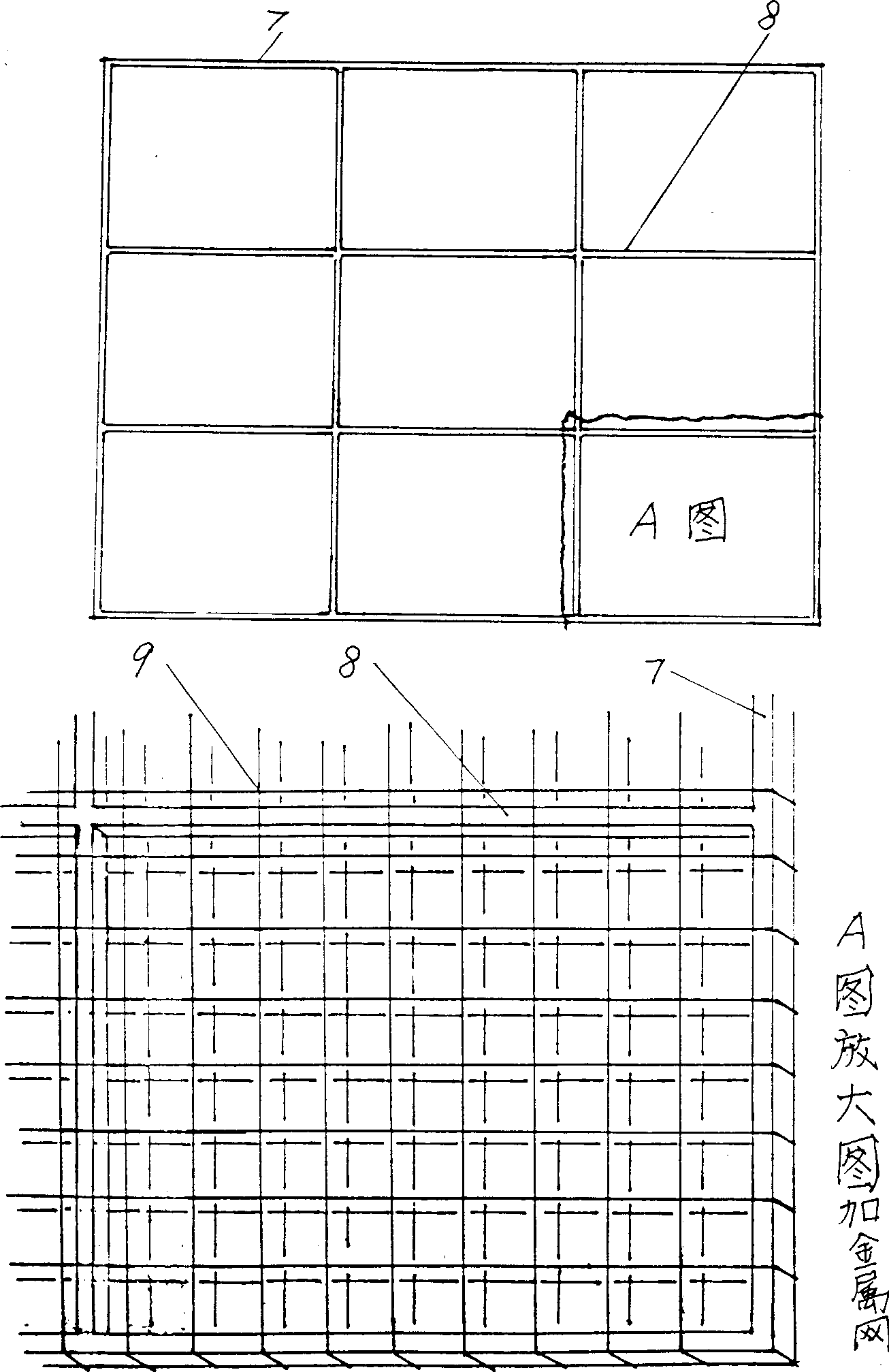

[0012] When making the wall of EPS foam bricks filled with metal mesh, the EPS foam bricks must be made first. The foaming of EPS foam has a ready-made technology. figure 2 The shape and size of the foam block half of the medium foam brick is made of metal aluminum. In the EPS foam factory, the foam block in the figure is formed by foaming with this mold. The hollow sides of the two foam blocks are facing each other with poly The styrene foam glue is bonded together to make a hollow EPS foam brick with reinforcing ribs. The length is about 2.3 meters, and the height is the same as the wall. The width is about 1.3 meters. One is 15 cm, which is used for interior walls, and the other is 20 cm, which is used for exterior walls. After you have the foam bricks, you need to make the metal mesh. According to the difference of the wall area, the metal mesh of the corresponding area is processed in the factory specializing in the production of metal mesh. The metal mesh is made of st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com