Horizontal smokeless and dust free boiler

A boiler and horizontal technology, applied in the field of horizontal smoke-free and dust-free boilers, can solve problems such as emissions, large investment in smoke-elimination facilities, heat loss, air pollution, etc., and achieve coal price savings, height reduction, and less flame damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

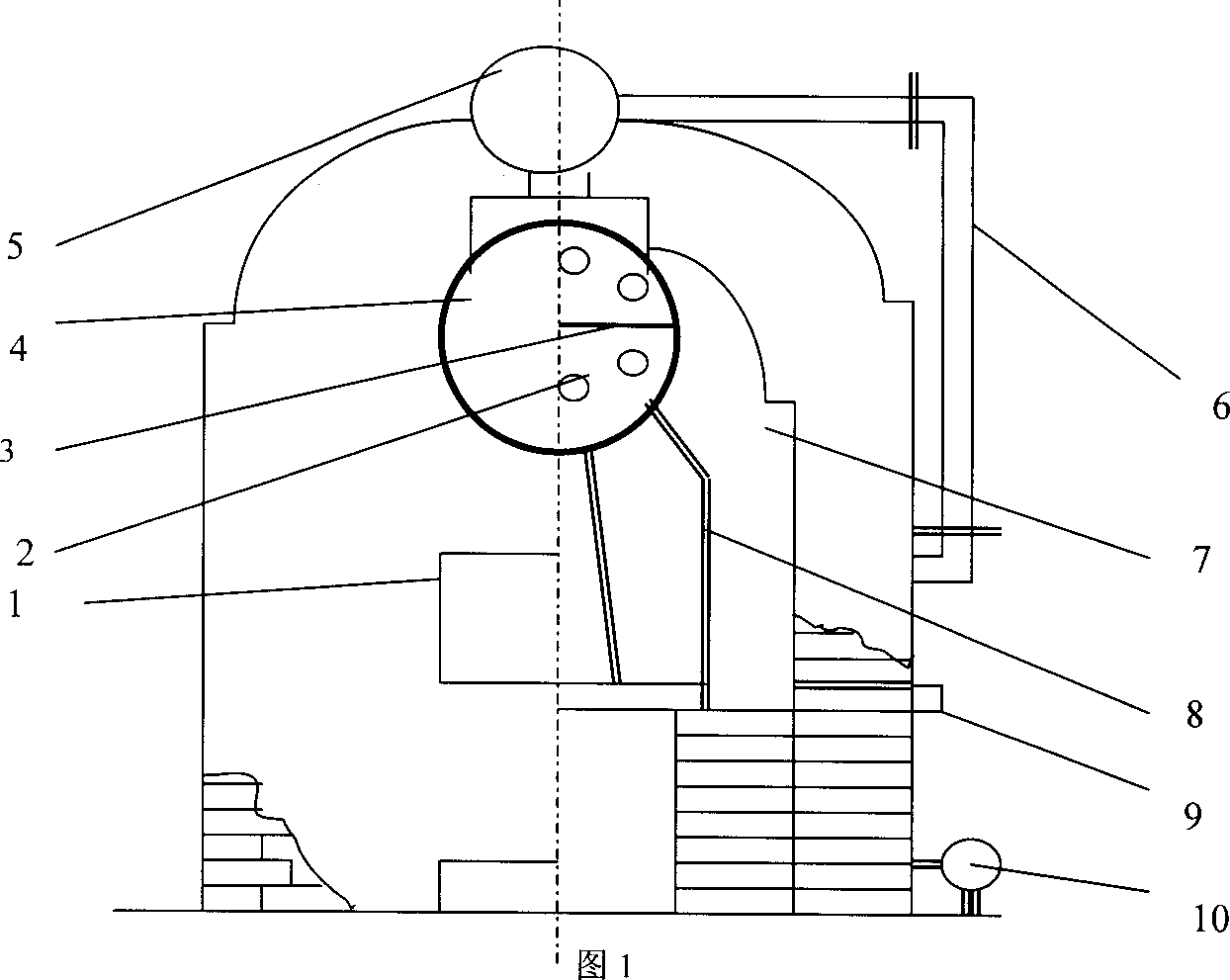

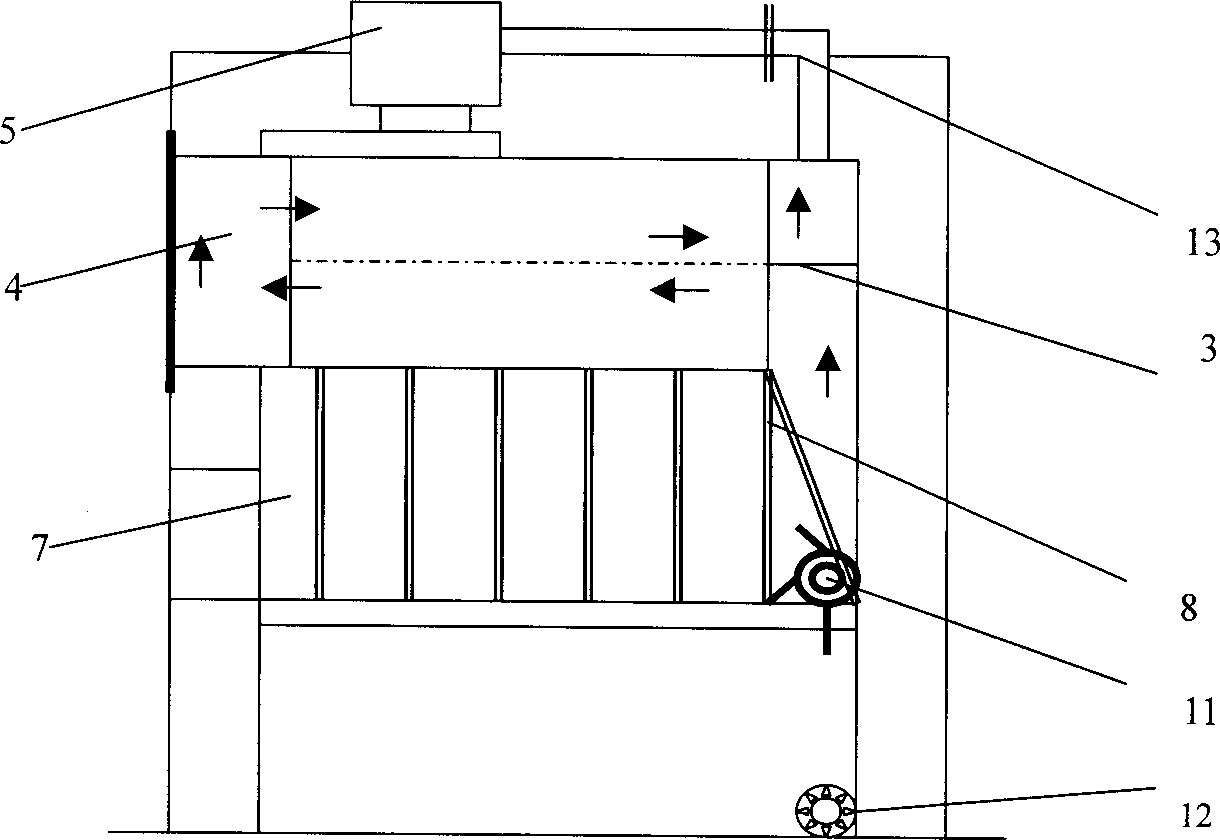

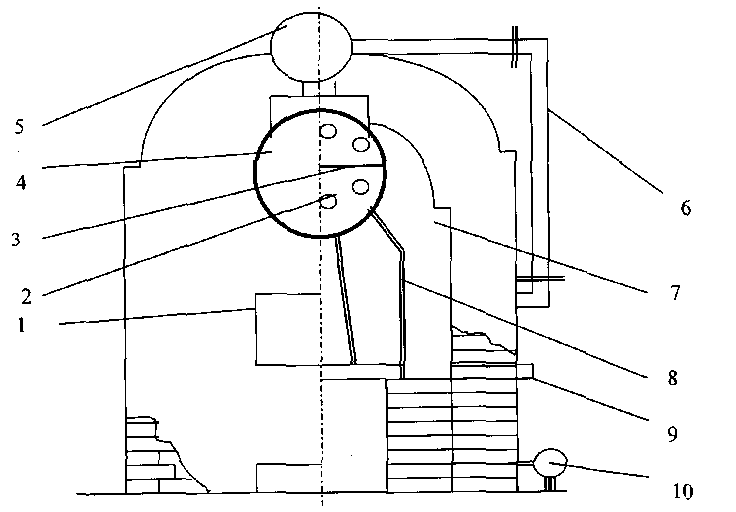

[0016] Horizontal smoke-free and dust-free boiler-type 1, machine below 0.5T, volume: length 1000mm, width 800mm, height 1100mm, material stainless steel, heat resistance 300-400 degrees, hot air circulation machine 300W, air volume 1500M 3 / N, wind pressure 350Pa, medium water, anthracite consumption 80kg / day, water capacity 60Kg, coke crushing roller length 500mm, diameter 50mm, with several pawls on the surface, coke discharge roller is a single-head hinged dragon, length 500mm, diameter 50mm , The air regulating valve is a one-way valve, which can control the air intake and the size of the flame. It is controlled by an electrified single-chip microcomputer, and with the coal device, it can realize automation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com