Process flow plate with temp. measurement feature

A technology of temperature measurement and flow plate, applied in the direction of temperature measurement of moving fluid, measurement of flow/mass flow, measurement of heat, etc., which can solve maintenance and installation complexity, increase installation and testing time, increase on-site installation time, etc. Problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

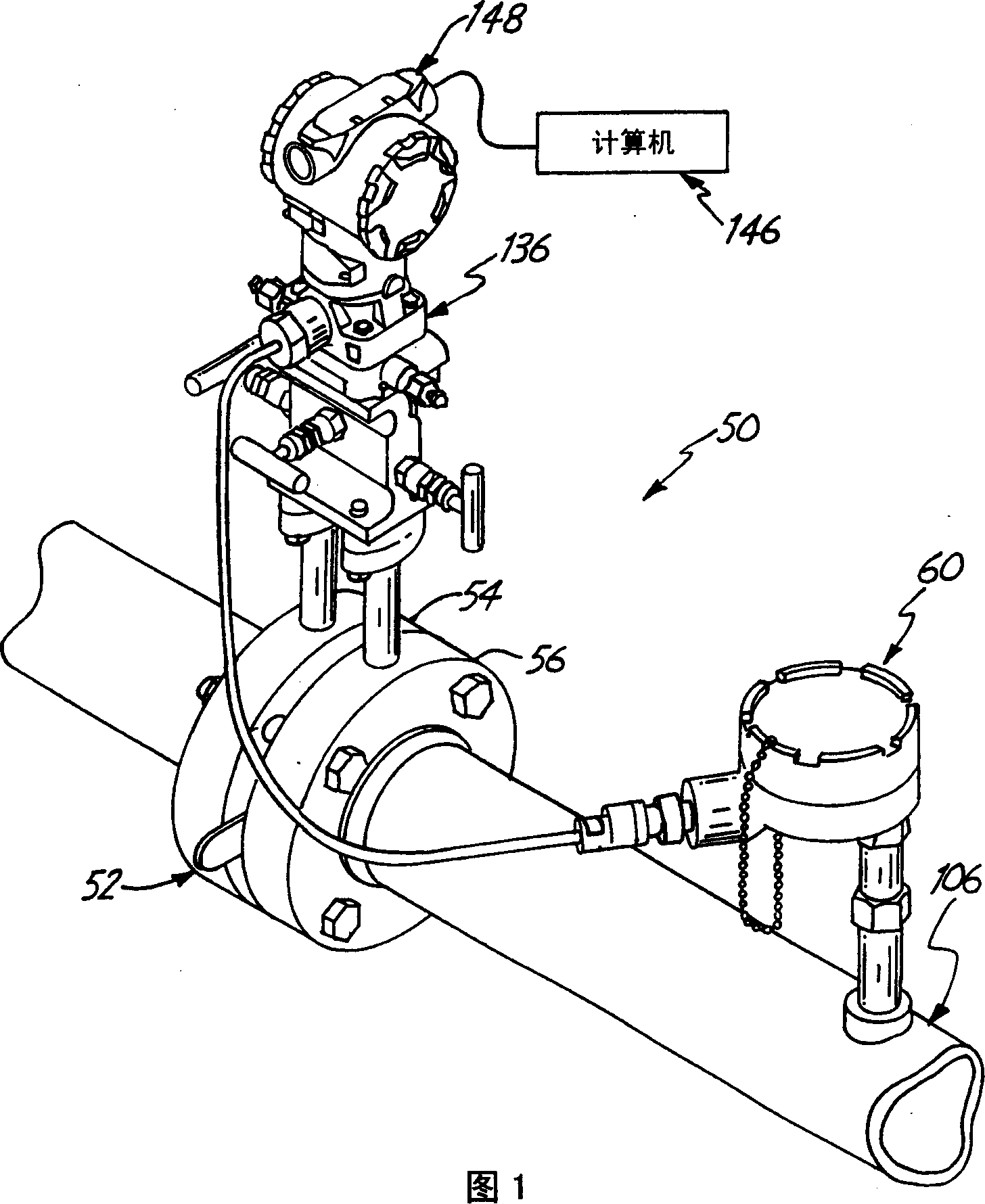

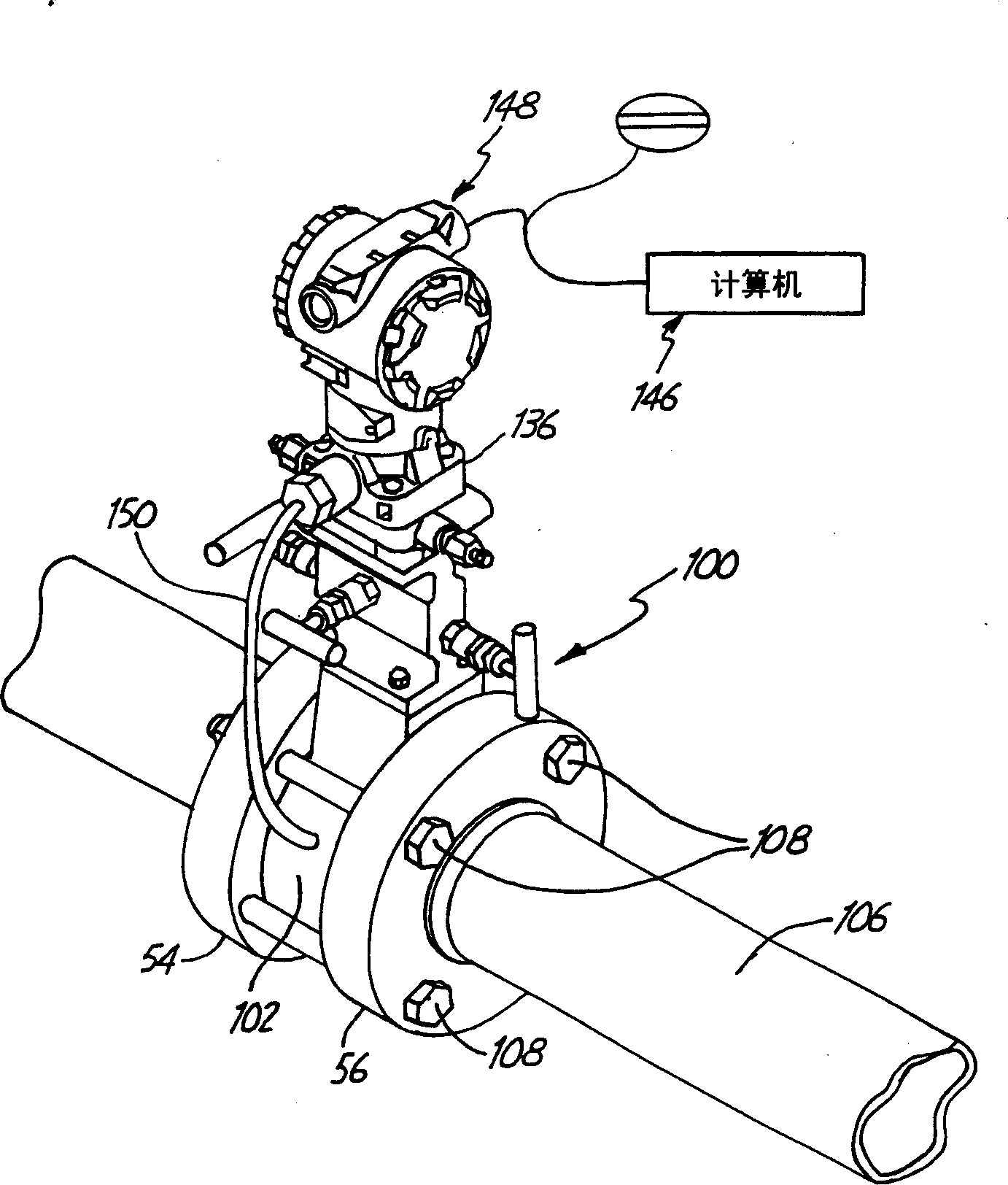

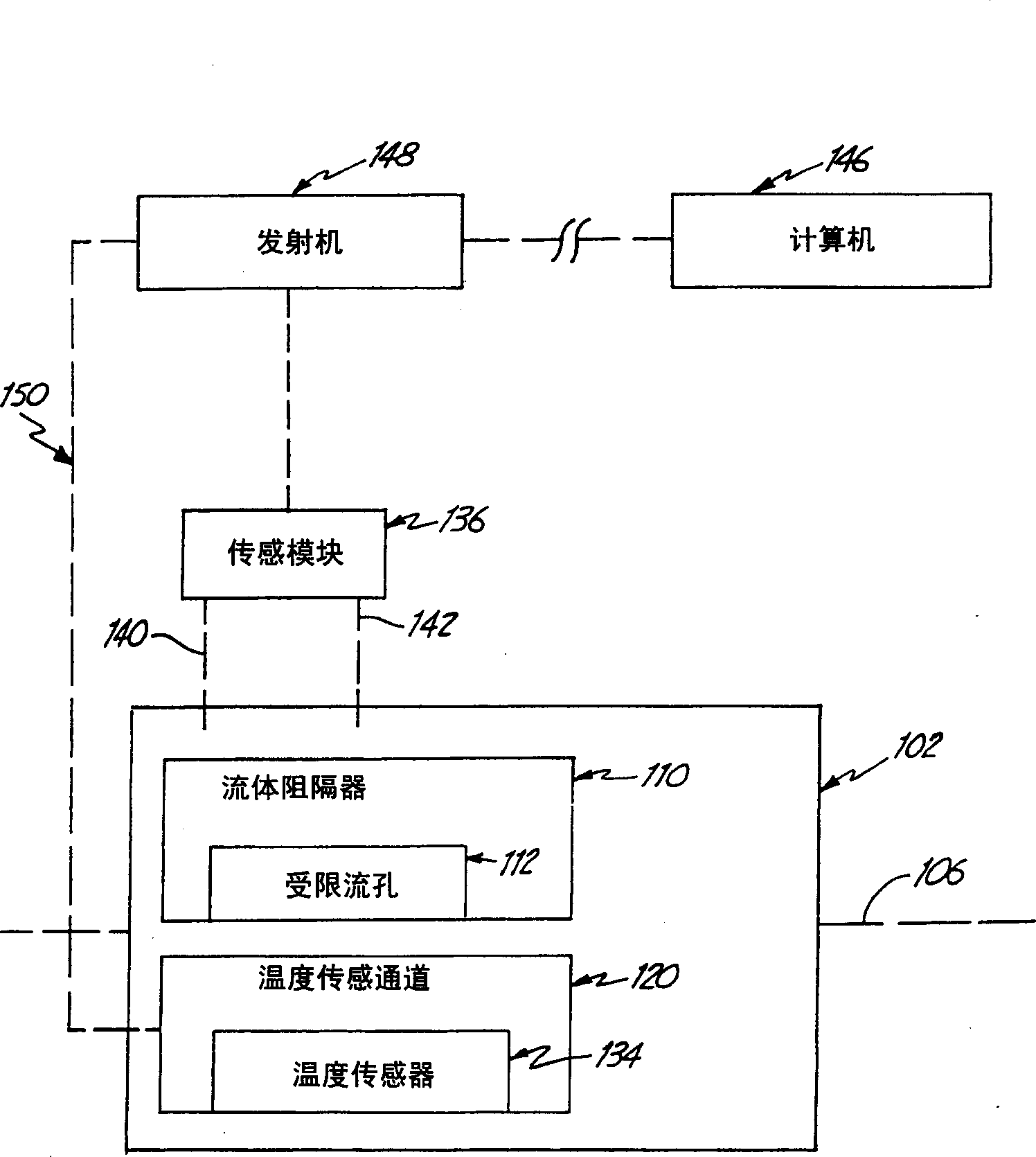

[0029] Figure 2-3 The environment of a flow device 100 including a flow plate 102 with an integral temperature sensor is described. As shown, flow plate 102 may be inserted between tube flanges 54, 56 in fluid channel 106, as figure 2 shown. In the illustrated embodiment, bolts 108 connect flanges 54, 56 to mount flow plate 102 within fluid passages 106 and tubes. Alternative connections may be used to mount flow plate 102 to fluid channel 106, and the application is not limited to the particular connections shown.

[0030] Flow plate 102 includes flow obstructors 110 extending along the perimeter of fluid passages or tubes 106, surrounding restricted flow openings 112, such as image 3 , 5 and 9. exist image 3 , 5 In and 9, the flow plate 102 is an orifice plate with restricted flow holes. An alternative flow obstructor 110 could be a nozzle plate (not shown) with restricted nozzle openings, and the flow obstructor 110 is not limited to an orifice plate. Detailed d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com