Production process of composite pipe with stainless steel lining

A production method and technology for lining pipes, which are applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high temperature resistance, high cost, high pressure, etc., and achieve the effect of good compression resistance and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

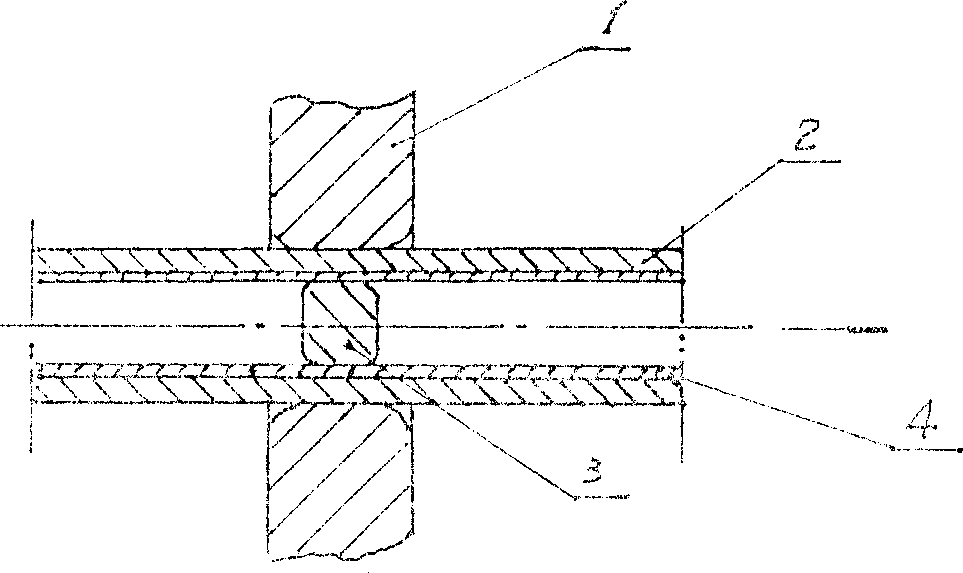

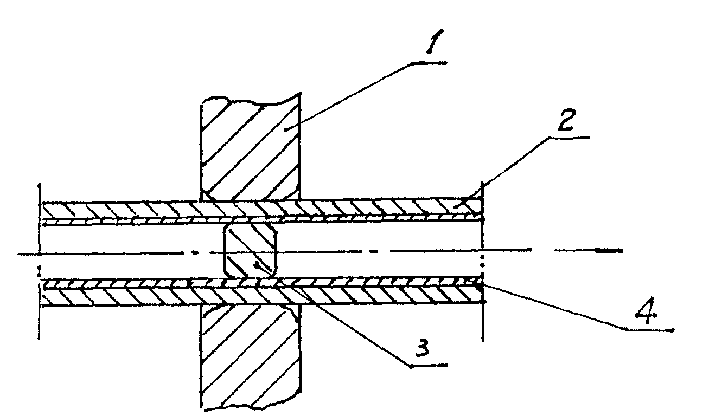

[0015] (1) Send the strip steel with the calculated feed into the ordinary welded pipe production line, process and produce qualified ones that are 0.5mm larger than the product specification requirements (excluding composite pipes produced by thermal expansion method), the outer diameter of which is passed through ordinary welded pipes, and removed Internal and external burrs make it suitable for production needs. Such as figure 1 The φ63.5×2.5 stainless steel strip is shown as an example. After processing, the diameter of the outsourcing tube 2 should be 0.5mm larger than the actual diameter of the outsourcing tube 2, which is φ64. The ellipticity requirement should not be greater than 0.02mm. Enter the next process after air tightness inspection and X-ray flaw detection;

[0016] (2) In order to produce the liner 4, promptly produce the liner 4 on the stainless steel pipe production line, the outer diameter of the liner 4 is: Dc=D-2t=63.5-2×2.5=58.5mm

[0017] Dc: Outer d...

Embodiment 2

[0023] (1) Send the strip steel with the calculated feed into the ordinary welded pipe production line, process and produce qualified ones that are 0.5mm larger than the product specification requirements (excluding composite pipes produced by the thermal expansion method), and the outer diameter of the ordinary welded pipes, and Remove internal and external burrs to adapt to production needs. Such as figure 1 The φ76 stainless steel strip is shown as an example. After processing, the diameter of the outsourcing tube 2 should be 0.5mm larger than the actual diameter of the outsourcing tube 2, which is φ76.5. Proceed to the next process after sex inspection and X-ray flaw detection;

[0024] (2) In order to produce the liner 4, promptly produce the liner 4 on the stainless steel pipe production line, the outer diameter of the liner 4 is: Dc=D-2t=76-2×3.0=70mm

[0025] Dc: Outer diameter of lining pipe (70mm)

[0026] D: The outer diameter of the outer cladding tube (76mm)

...

Embodiment 3

[0031] (1) Send the strip steel with the calculated feed into the ordinary welded pipe production line, process and produce qualified ones that are 0.5mm larger than the product specification requirements (excluding composite pipes produced by the thermal expansion method), and the outer diameter of the ordinary welded pipes, and Remove internal and external burrs to adapt to production needs. Such as figure 1 The φ114 stainless steel strip is shown as an example. After processing, the diameter of the outsourcing tube 2 should be 0.5mm larger than the actual diameter of the outsourcing tube 2, which is φ114.5. Proceed to the next process after sex inspection and X-ray flaw detection;

[0032] (2) In order to produce the liner 4, promptly produce the liner 4 on the stainless steel pipe production line, the outer diameter of the liner 4 is: Dc=D-2t=114-2×4.0=106mm

[0033] DC: Outer diameter of lining pipe = 106mm

[0034] D: The outer diameter of the outer cladding tube = 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com