Fuzzy control film-coating process for electric heating film

A technology of fuzzy control and electric heating film, applied in metal material coating process, liquid chemical plating, coating, etc., can solve the problems of high cost of electric heating elements, power difference of electric heating film elements, difficulty in popularization and application, etc., and achieve high Economic and social benefits, improving the rate of qualified products, and realizing the effect of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

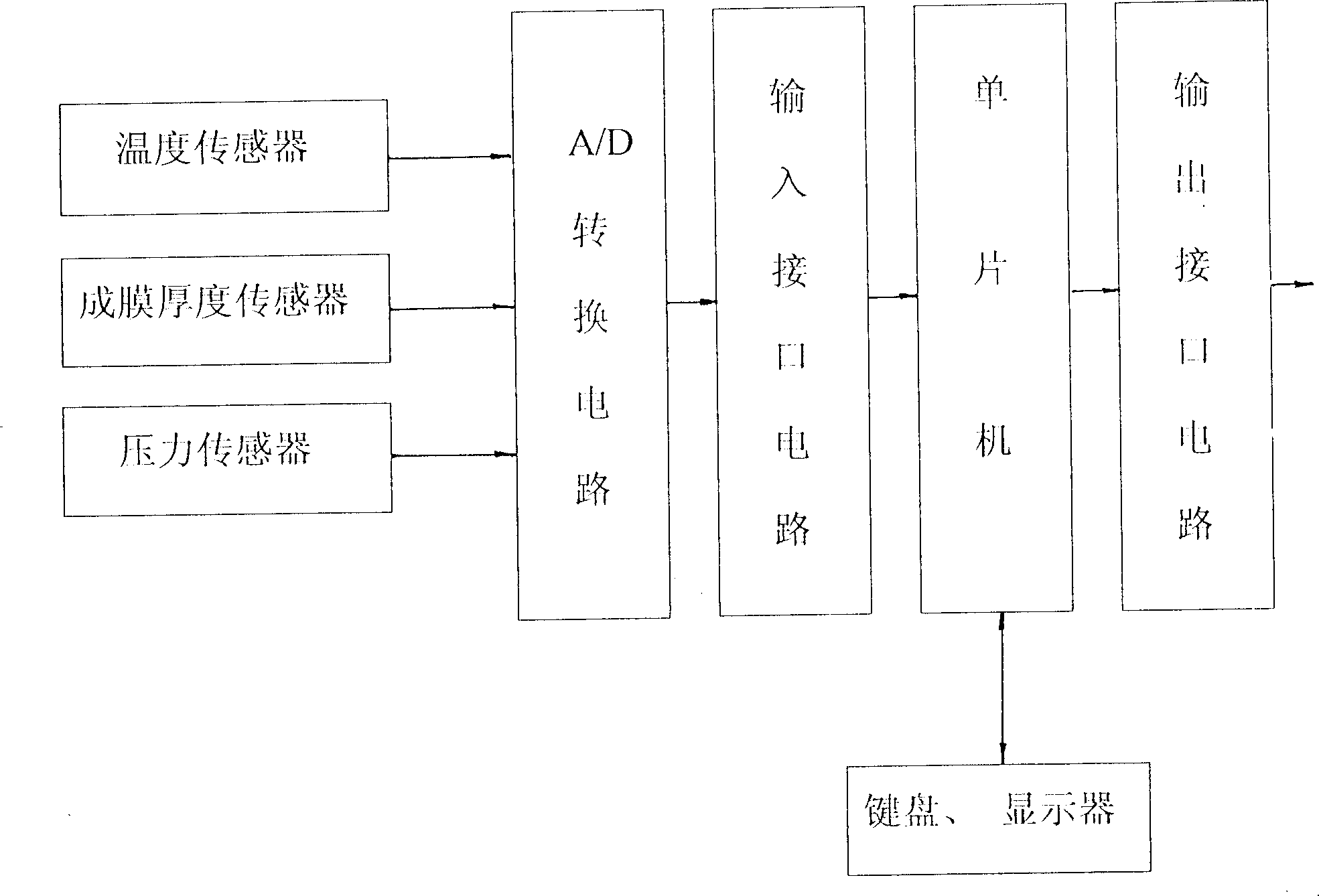

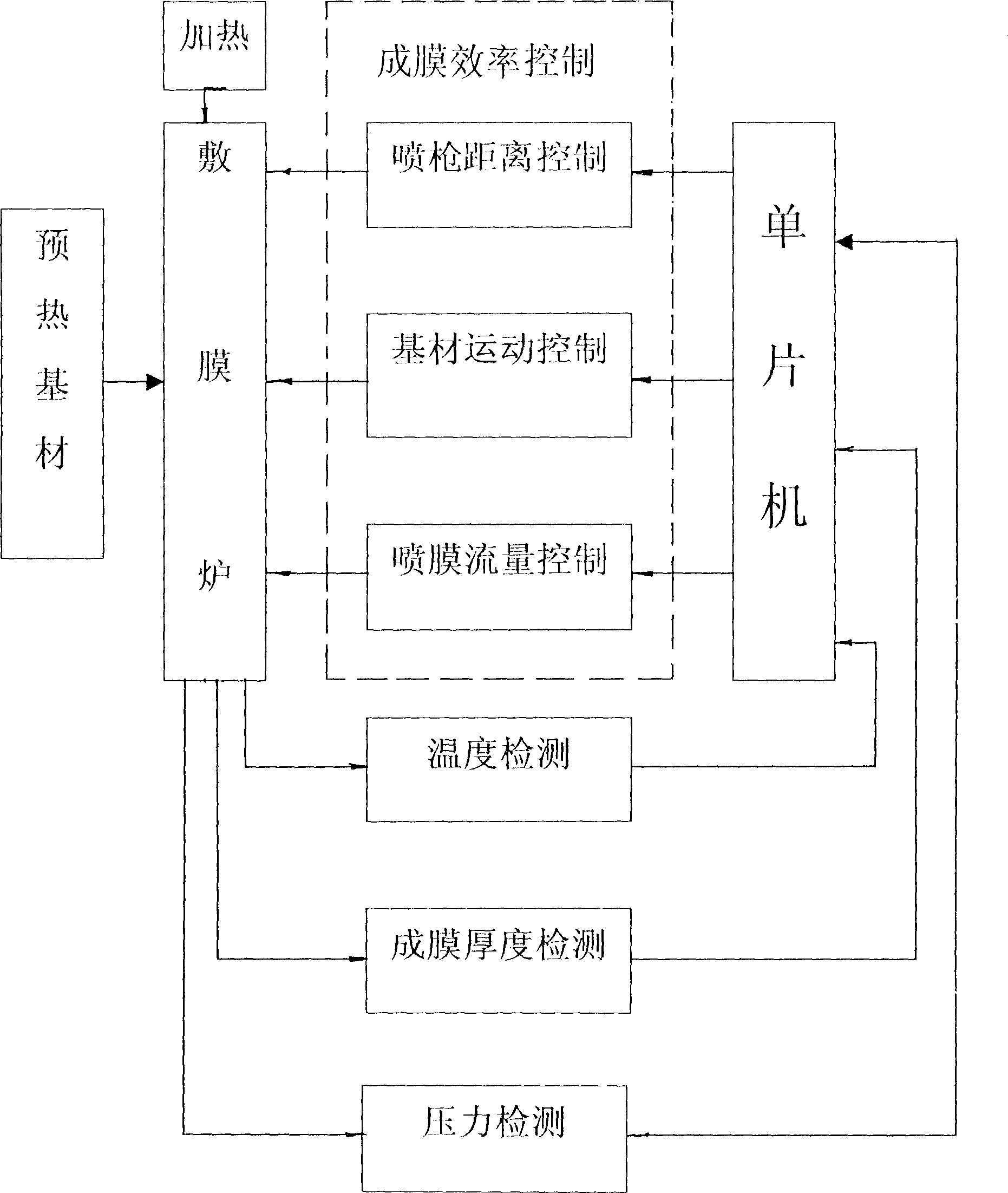

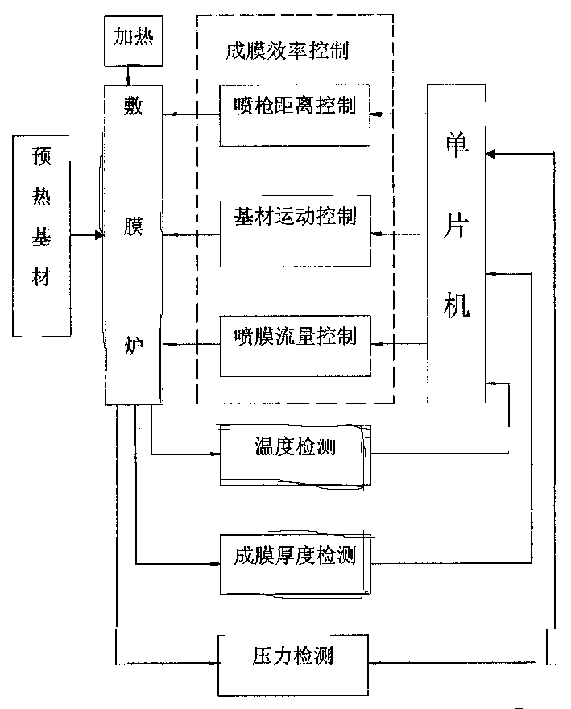

[0021] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings. Such as figure 1 Shown is the circuit principle block diagram of the embodiment of the present invention. The structure of the coating furnace in the embodiment of the present invention is basically the same as the coating furnace in the prior art, that is, a fixture for clamping the base material is installed in the coating kiln, and a device that can control the movement of the base material is also installed in the coating kiln. The base material can be rotated with the center as the axis, and can move in parallel at the same time. Different from the prior art, the positions of the electrothermal film spray gun and the base material can be adjusted through electric signal control, such as an electric manipulator. In the pipeline where the electrothermal film liquid enters the spray gun, there is an element that can adjust the flow rate of the electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com