Hole-forming drilling mahcine with planetary movement for foundation engineering with large-diameter piles

A basic engineering and large-diameter technology, applied in the field of large-diameter drilling tools, can solve problems such as difficulties, and achieve fast and thorough hole cleaning, efficient slag removal, and brand-new structural principles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

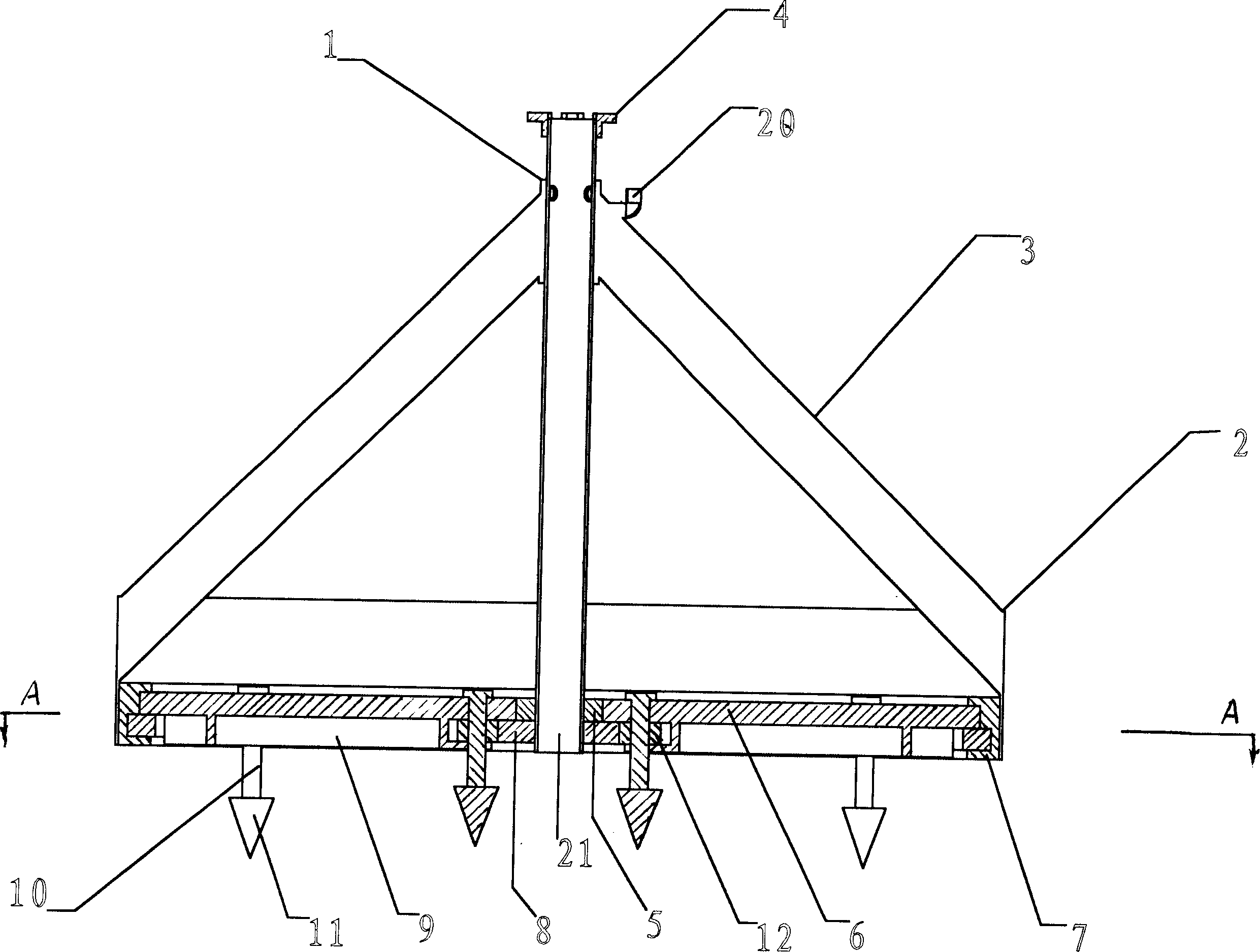

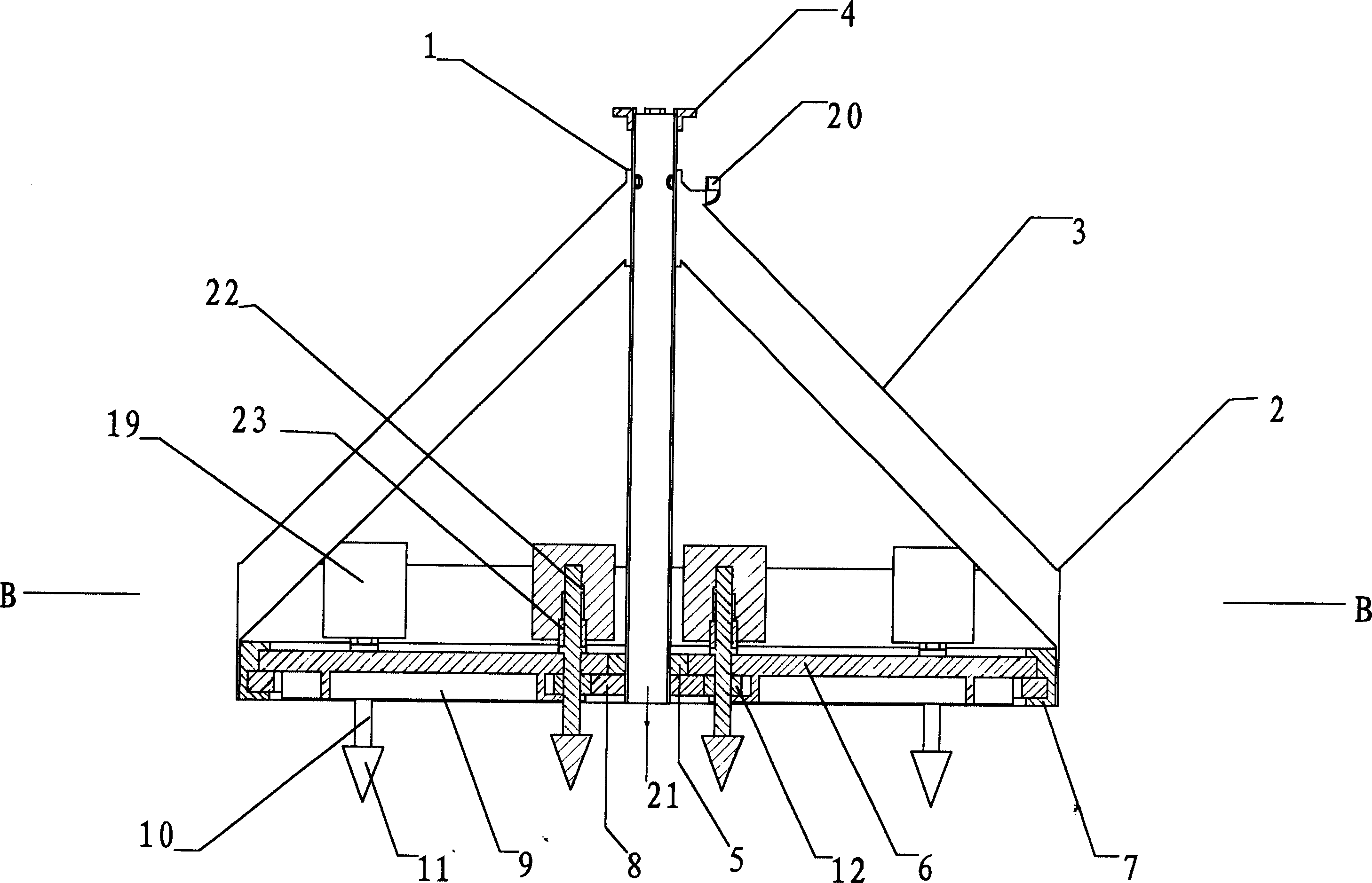

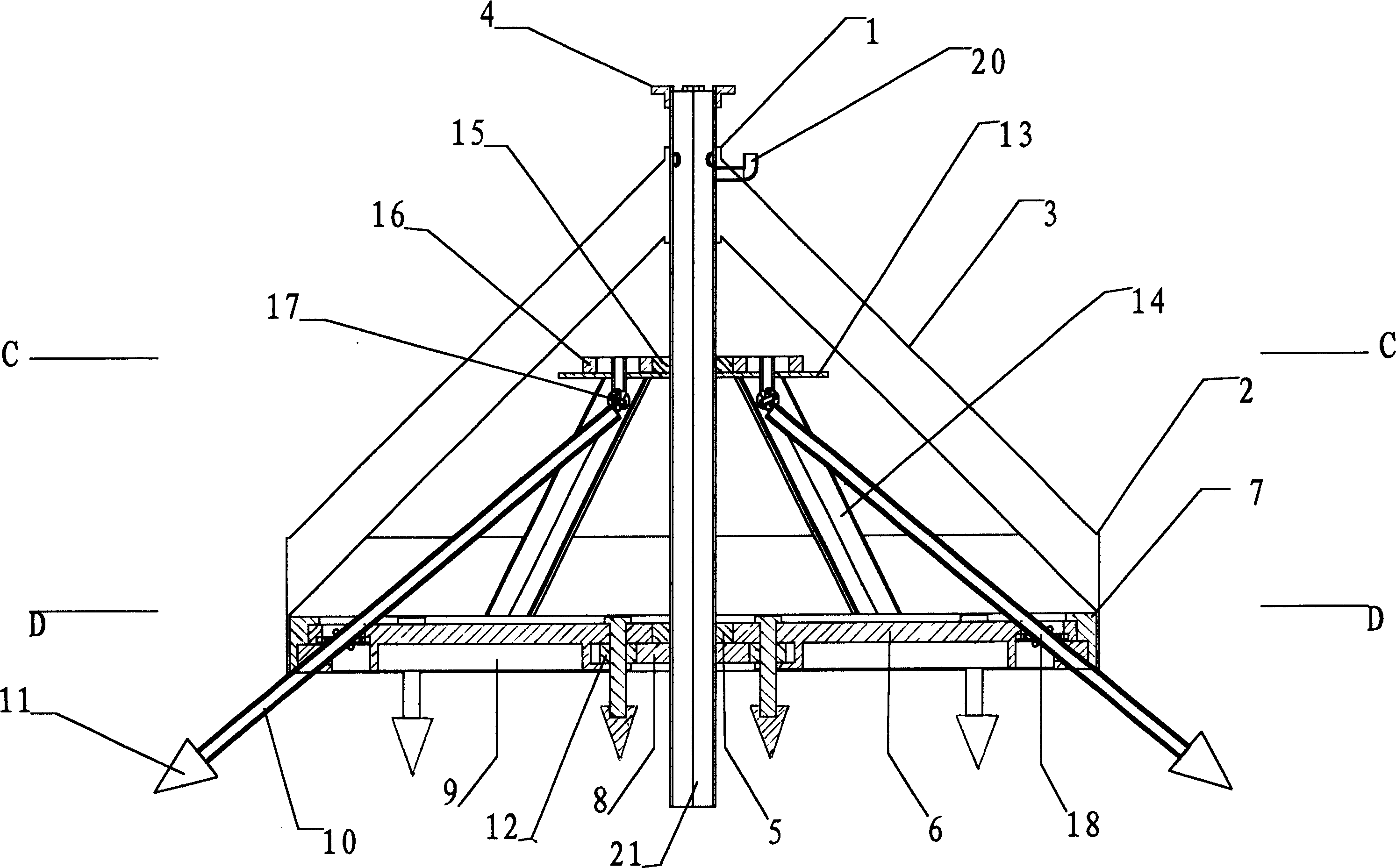

[0016] exist figure 1 In the first embodiment, the drill frame is welded by the upper bracket ring (1), the lower bracket ring (2) and the inclined struts (3) between them, and the power shaft (4) is a hollow garden rod, which is connected with the upper The bracket ring (1) is fixed with bearings, and in the lower bracket ring (2), the central gear (5) is fixed on the power shaft (4) with keys, and the three planetary gears (6) are evenly distributed around the central gear (5) , the planetary gear (6) and the sun gear (5), the inner teeth of the upper part of the gear ring (7) are meshed at the same time, the gear ring (7) and the lower bracket ring (2) are connected together with screws, the inner circle of the gear ring (7) The lower section of the circumference is a smooth cylindrical surface, which cooperates with the outer circumference of the tray (8). The tray (8) is a smooth disc with three planetary holes corresponding to the planetary gear (6). (9), ring gear is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com