Microconcave digital controlled laser formation method and device on working surface of friction pair

A working surface, CNC laser technology, used in laser welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of unsuitable processing of high-hardness materials, insignificant, increased friction pair life, etc., and achieve significant economic and social benefits. Benefit, improve wear resistance, ensure consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

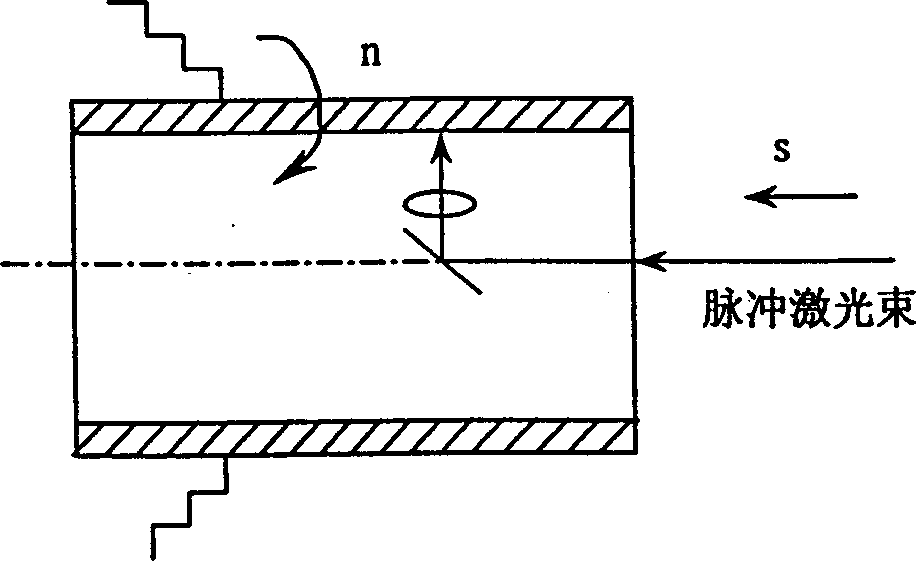

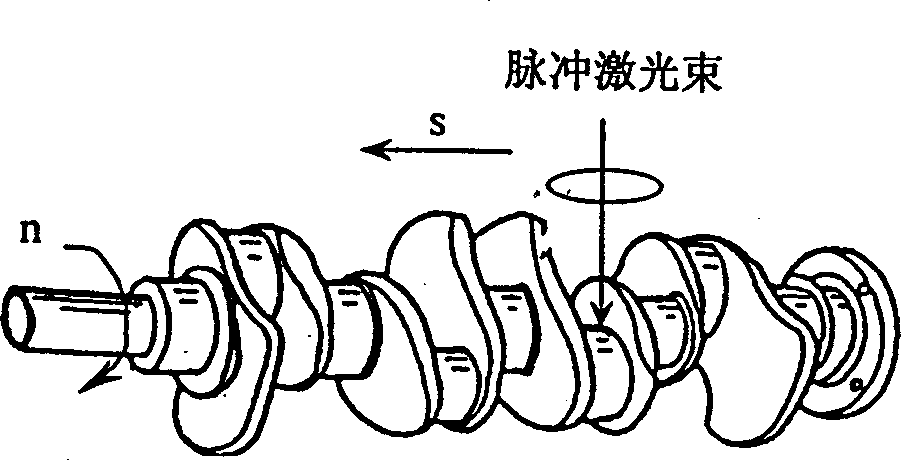

[0019] The micropit CNC laser forming device on the working surface of the friction pair is that the motor 1 drives the laser spindle 5 to perform linear motion through the pinion 2, the big gear 3 and the ball screw 4; the motor 13 drives the transmission shaft 17 to rotate through the pinion 15 and the big gear 14, The small gear 12 and the large gear 11 transmit the rotation of the transmission shaft 17 to the transmission shaft 10, driving the rotation of the workbench 9; the fixture 8 is installed on the workbench 9, and the cylinder 27 is installed in the fixture 8; the numerical control system controls the motor 1, the motor 13 to control the movement speed of the laser spindle 5 and the workbench 9.

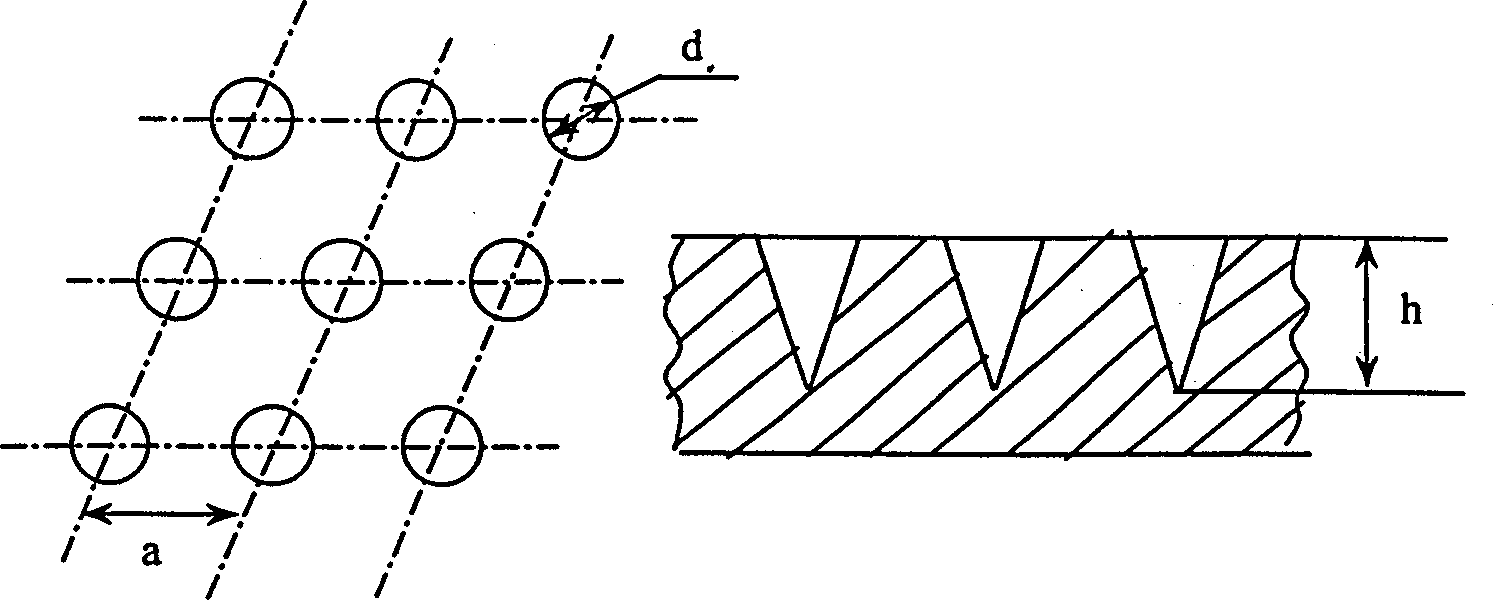

[0020] Such as figure 1 As shown, the relationship between the working parameters of the machine tool and the parameters of the micropit of the cylinder liner is determined by the following relationship: a = π ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com