Electric machine driving device

A motor drive and voltage technology, applied in AC motor control, output power conversion device, electronic commutation motor control, etc., can solve the problems of motor 1 and mechanical system breakage, increase production cost, unstable speed control of motor 1, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] An embodiment of the present invention is described below with reference to the accompanying drawings. (Structure of motor drive unit)

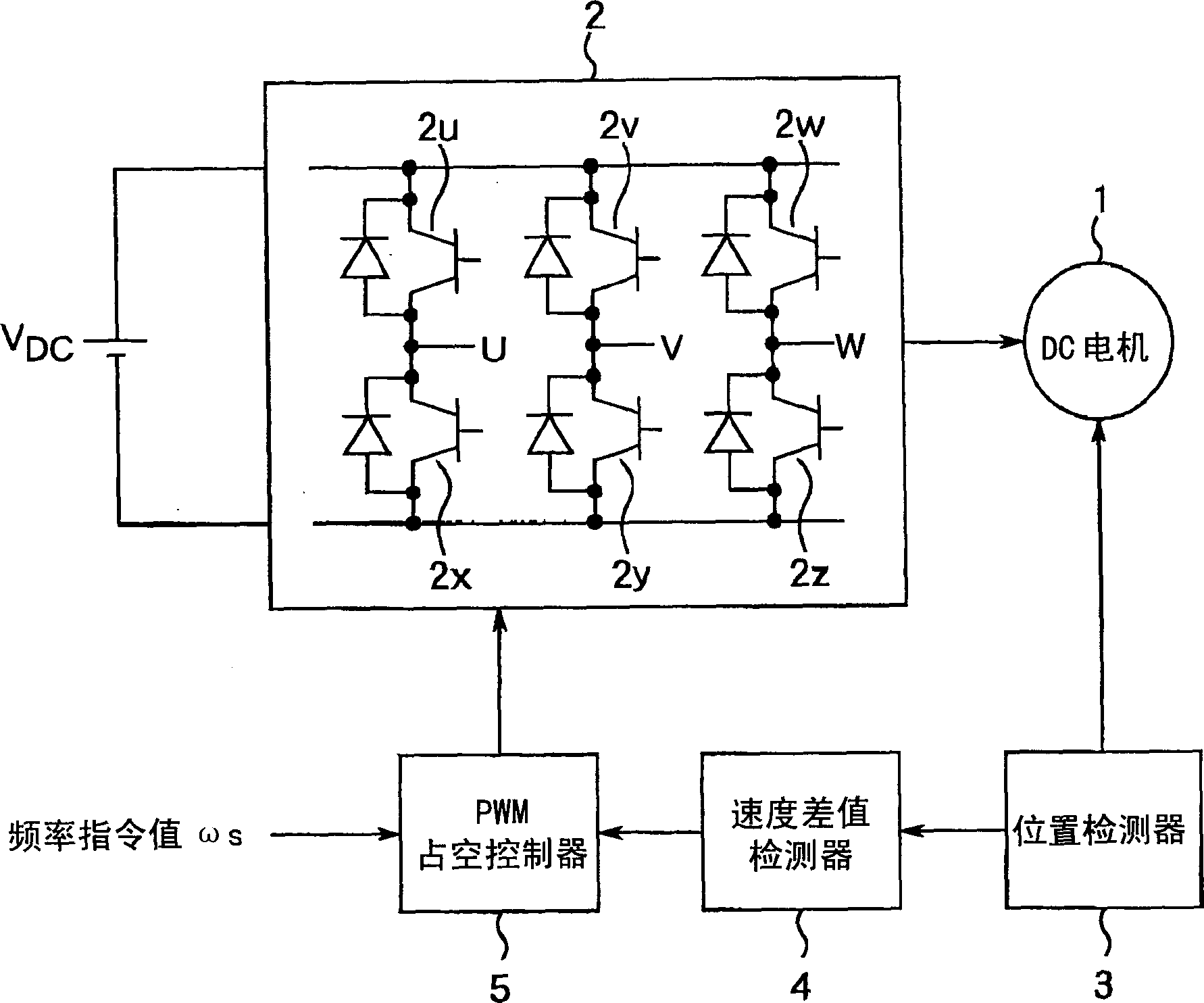

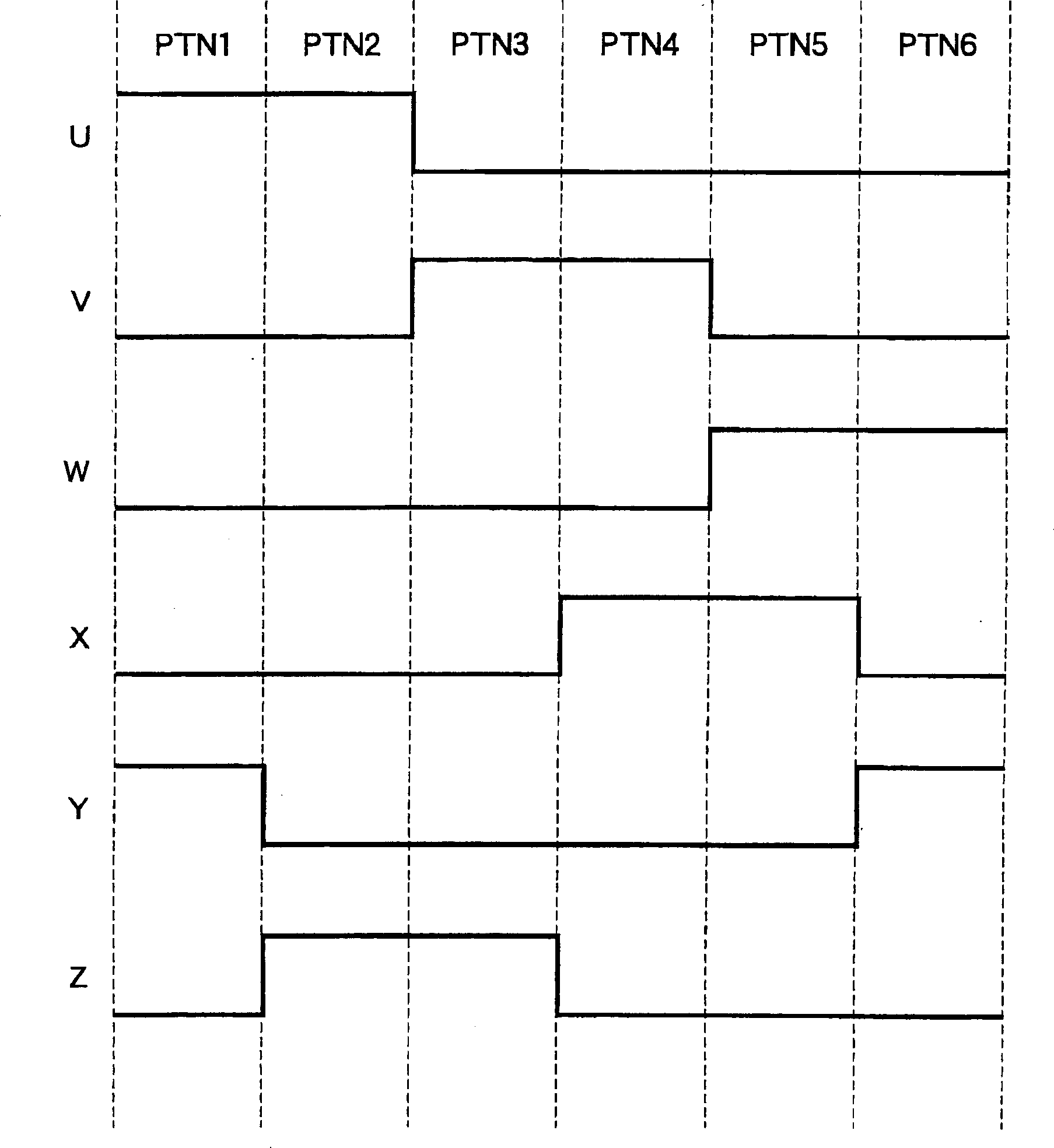

[0022] figure 1 The structure of the motor drive device according to the specific embodiment of the present invention is shown. figure 1 The motor drive device is arranged to be able to control the number of revolutions of the three-phase np poles (np is an even number not less than 4) of the brushless DC motor 1 by 120° excitation control (square wave excitation control).

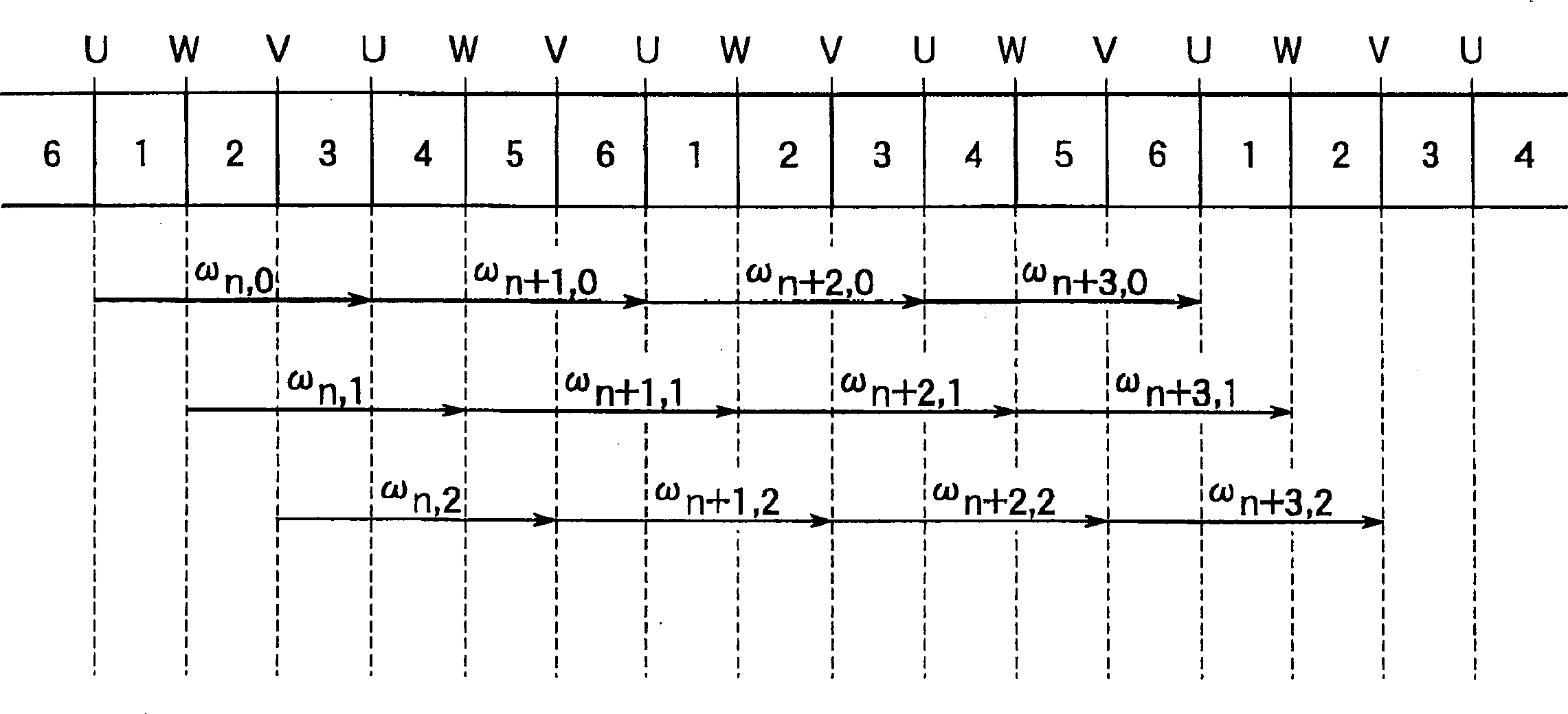

[0023] Such as figure 1 As shown, this motor driving device includes: a DC / AC converter 2 for converting a DC voltage into a pseudo AC voltage to output a pseudo AC voltage to the motor 1; a magnetic pole position detector 3 for detecting the rotor position of the motor 1 ; A speed difference detector 4 for detecting the rotational speed of the motor 1 from the rotor position of the motor 1 measured by the magnetic pole position detector 3, and a pulse width ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com