Reel for supporting composite coiled tubing

A technology of reeling and reeling pipes, which is applied to drilling pipes, casings, thin material processing and other directions, can solve the problems of undisclosed storage methods and undisclosed composite pipes, and achieve the effect of reducing the possibility and prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

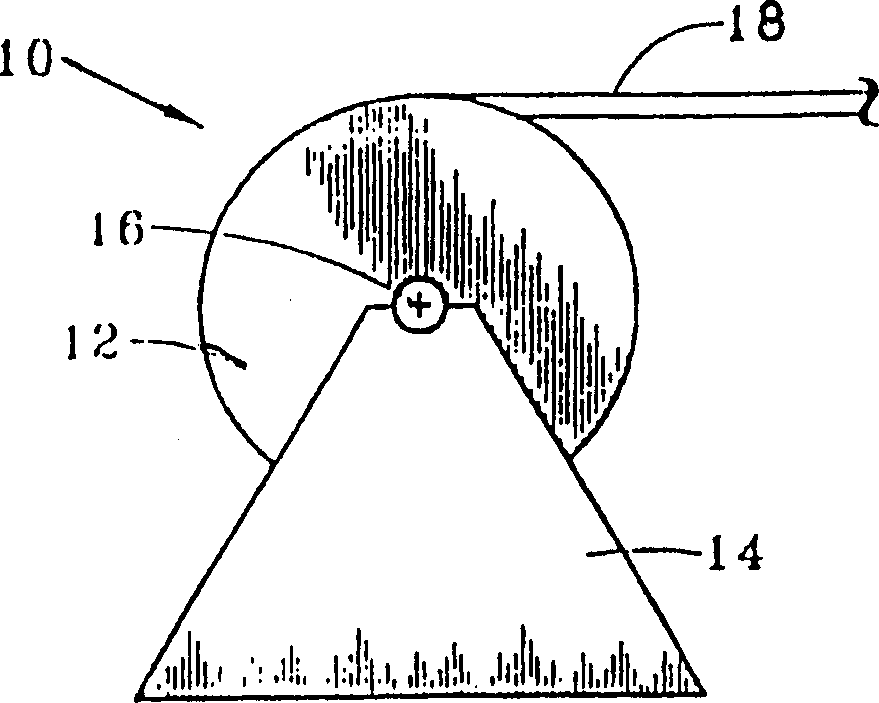

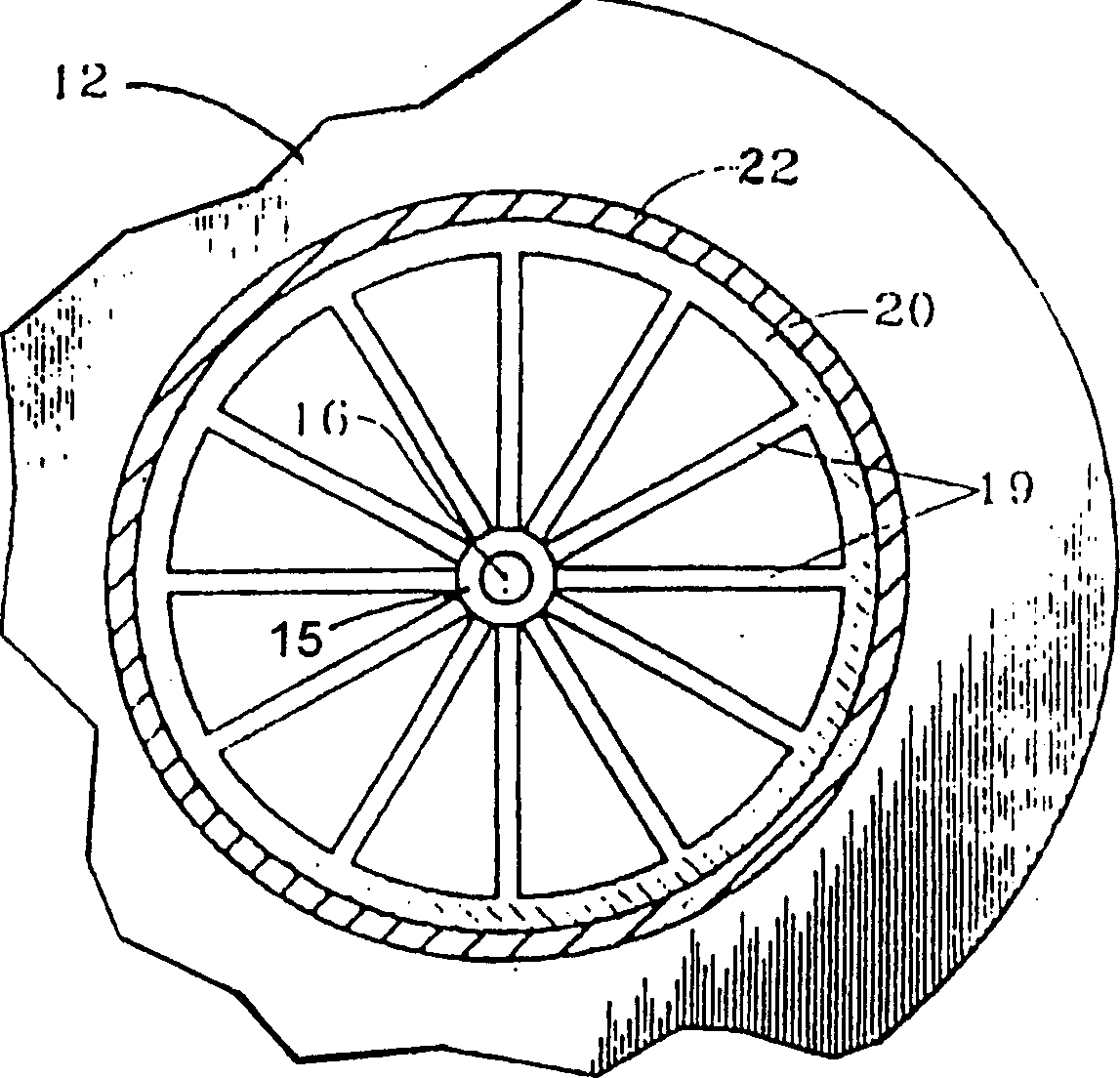

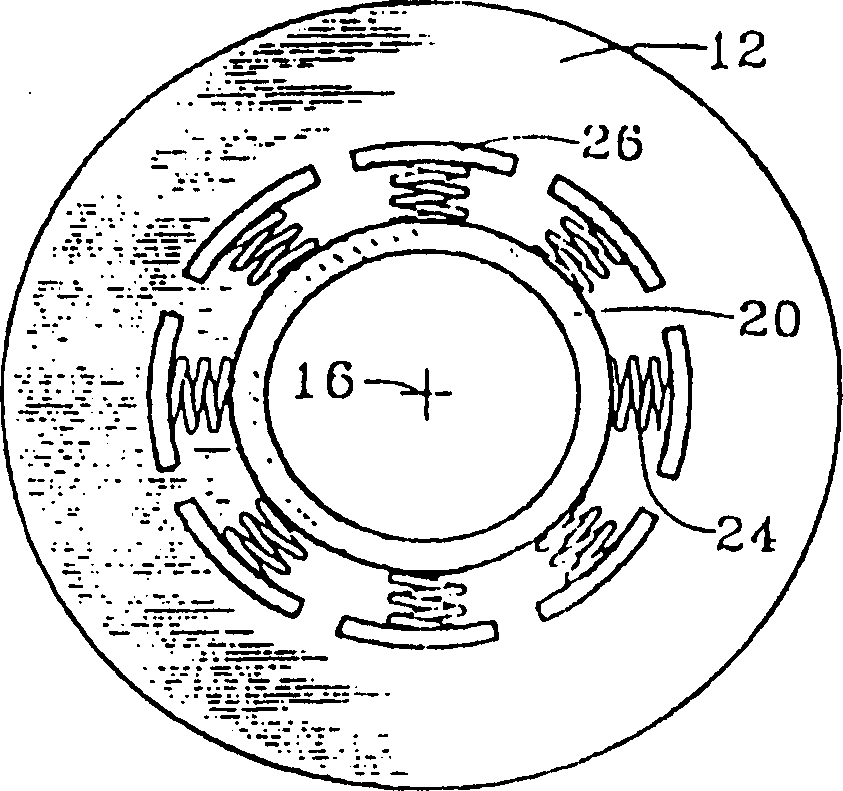

[0032] Reference to the drawings is for the purpose of describing the preferred embodiments only and not for the purpose of limiting the embodiments. figure 1 Generally shown is a drum or reel 10 for supporting and / or transporting composite coiled tubing. The spool 10 is typically transported by truck, barge or ship, and is transported in bundles of the spool and coiled tube, often referred to as a coiled tube unit. figure 1 Composite tubing 18 is also shown being uncoiled and extended from coiled tubing unit 10 for processing, eg, concentrically lowered into a subterranean well for downhole operations. figure 2 generally expressed figure 1 Shown or is a cross-sectional view of the reel 10 with the composite conduit 18 removed for clarity. also, figure 2 Also shown are some components of a preferred embodiment, including flexible material 22 affixed to the outer surface of hub 20 .

[0033] In a preferred embodiment, the outer hub 20 is mounted on a base 14 and is rotata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com