Elliptical gear press without crank

A technology of oval gears and presses, applied in presses, stamping machines, manufacturing tools, etc., to achieve the effects of high transmission efficiency, easy adjustment, stable and reliable speed change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

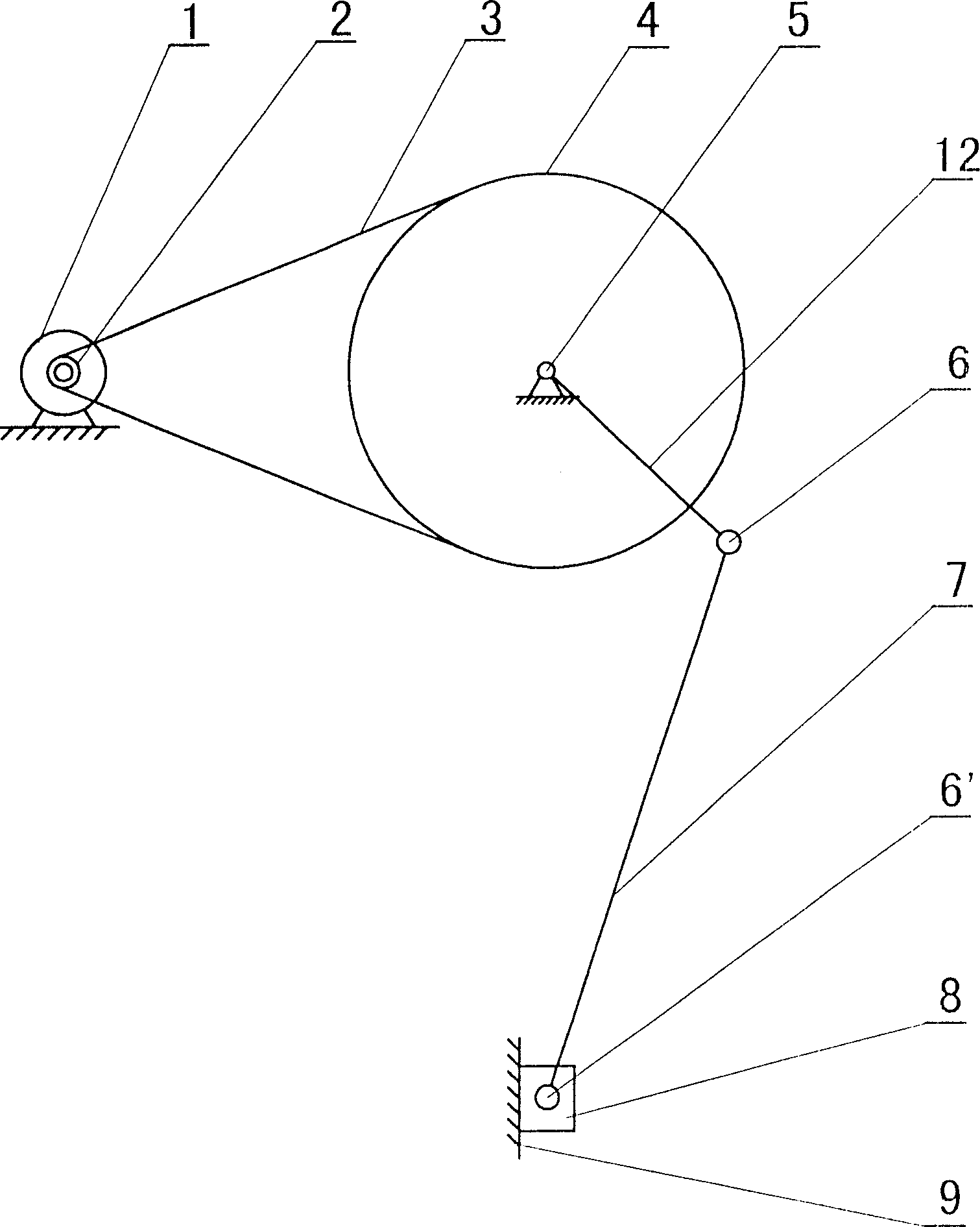

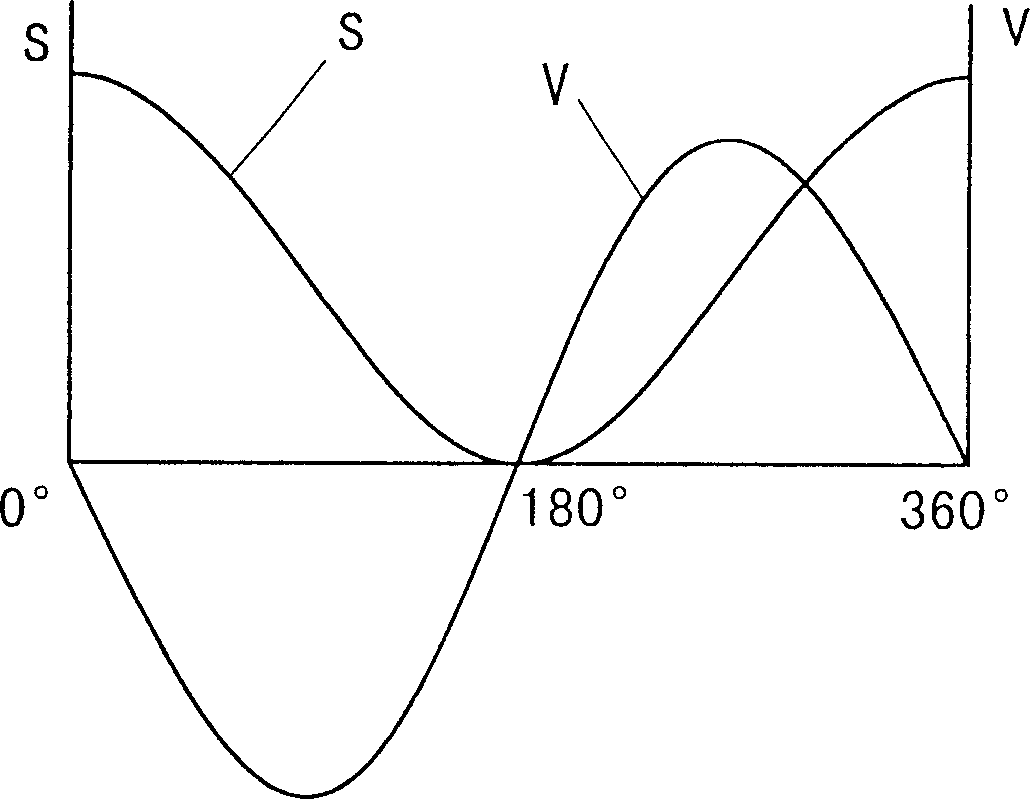

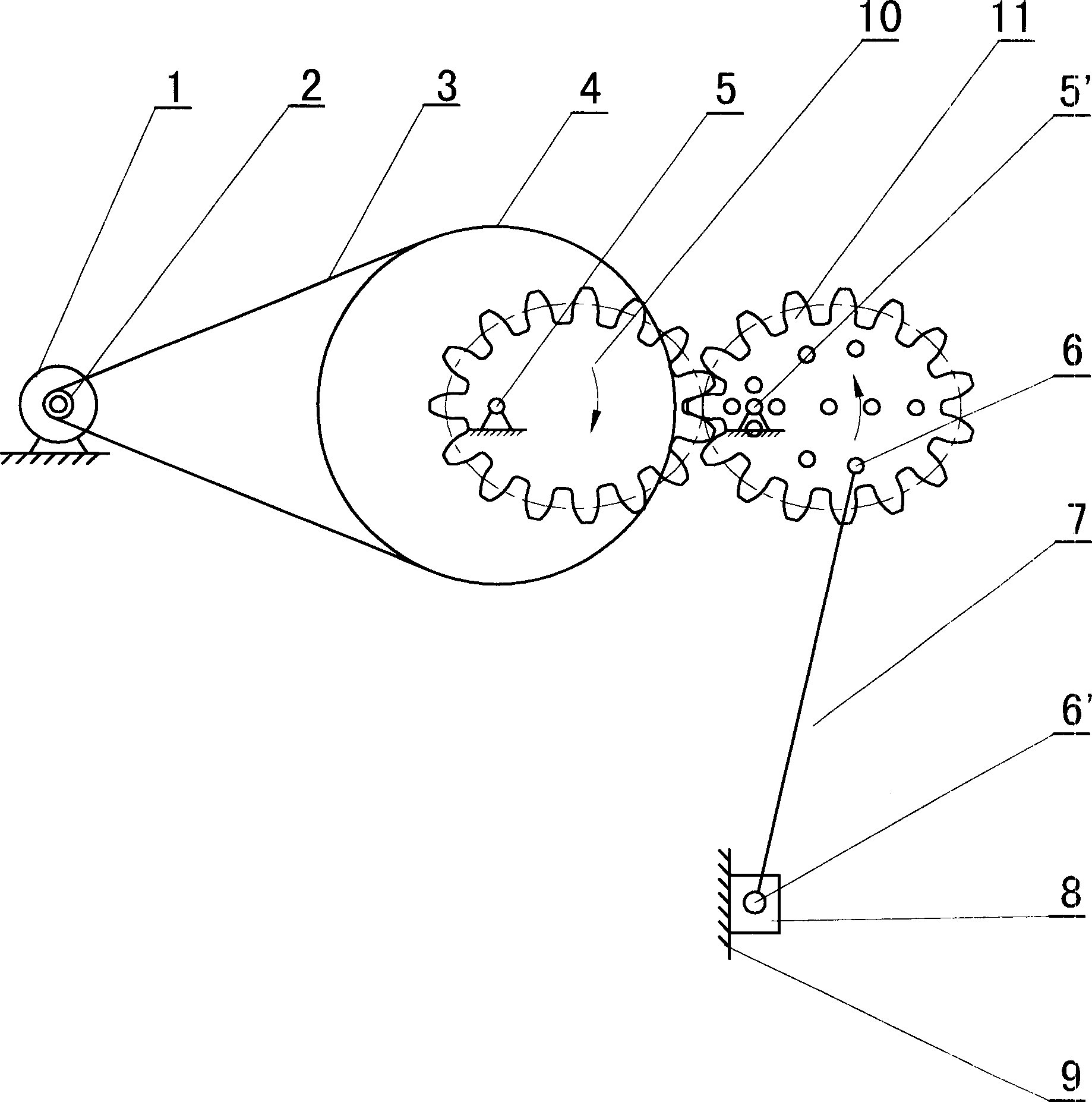

[0022] Such as Figure 4 As shown, the present invention makes the variable speed motion characteristic of the elliptical gear due to the change of the included angle α between the elliptical major axis 111 of the passive elliptical gear 11 and the center of rotation 112 of the passive elliptical gear 11 and the center line of the connecting pin 6 mounting hole 113. The superposition position of the curve and the kinematic characteristic curve of the crank slider is different, so that the same press can easily change the kinematic characteristic curve of the slider. The present invention utilizes the change of the distance L between the center of rotation 112 of the passive oval gear 11 and the connecting point 113 of the connecting rod 7, so that the same press can easily change the stroke of the slider. Therefore, the change of these two parameters enables the present invention to be widely used in the field of pressure processing such as deep drawing processing, precision p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com