Method for centralizing illuminator of back light assembly and combined light guide plate

A technology of backlight assembly and light guide plate, which is applied in the direction of light guide, optical element, light guide of lighting system, etc., can solve the problems of wasting power and projecting on the A1 side of the light guide plate A, etc., to reduce the defect rate and improve the brightness of the light source. , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

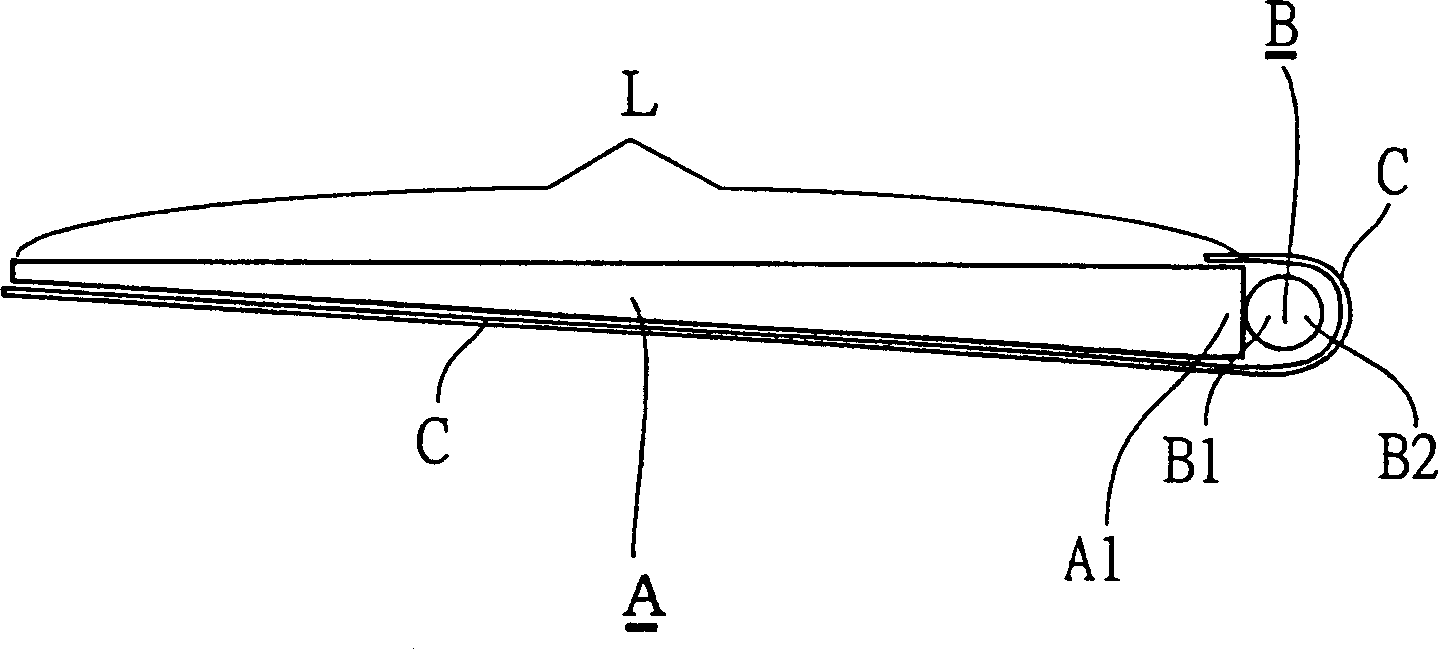

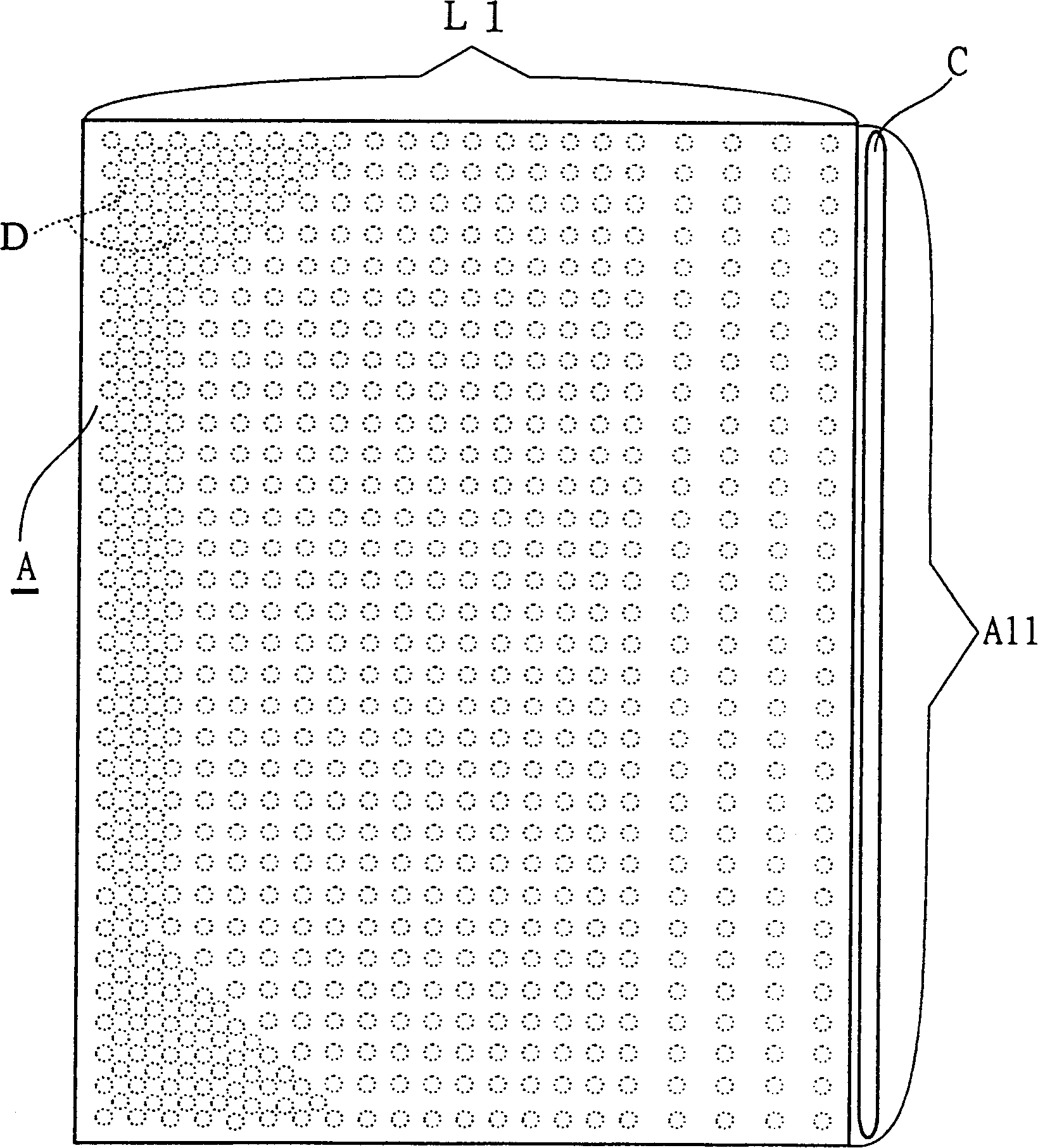

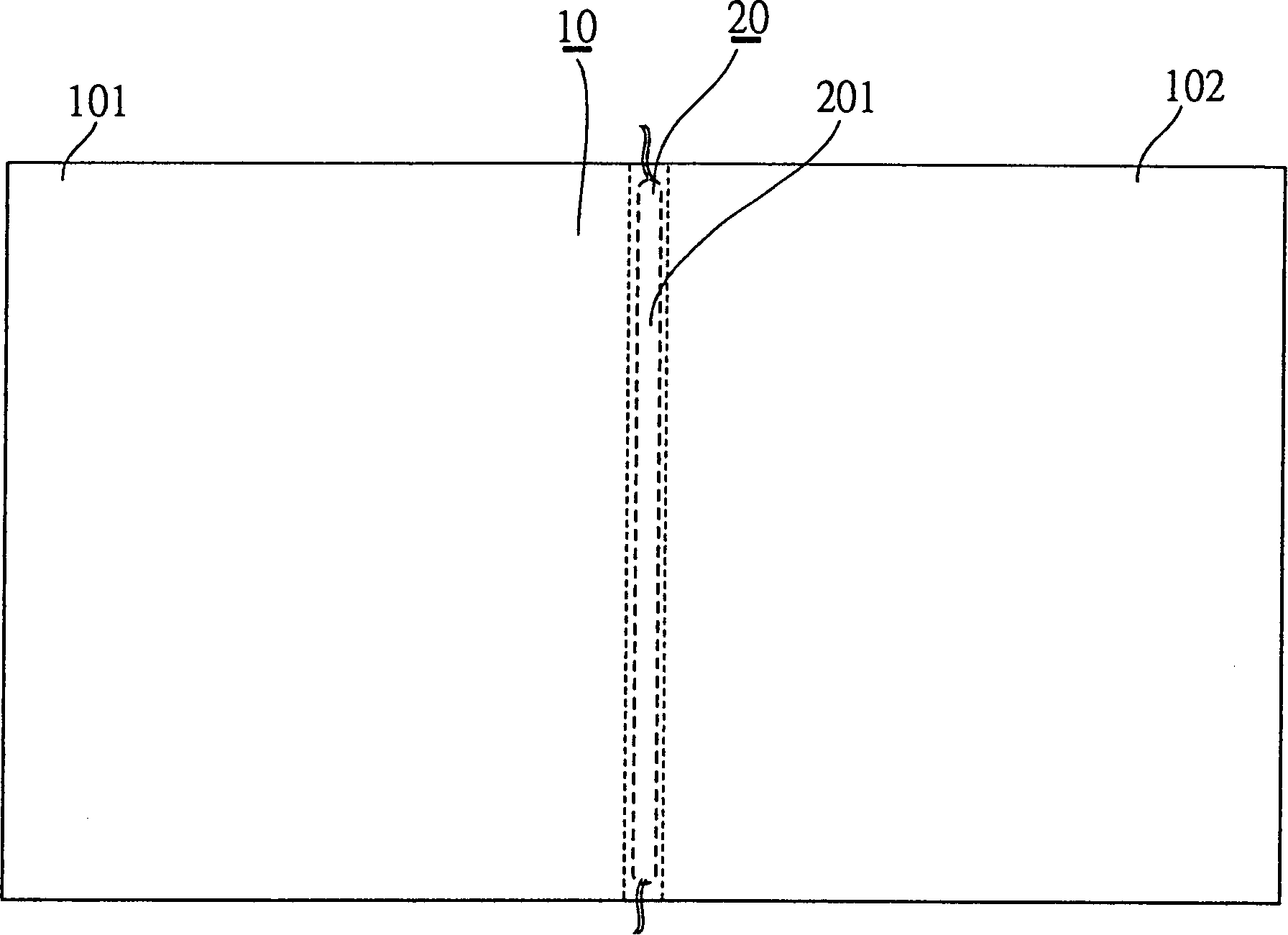

[0056] Please check the photo image 3 and Figure 4 ,like image 3 Shown, the present invention mainly is by; Have the light guide plate 10 and illuminant 20 that are sheet-like with two ends and constitute; Please check according to Figure 4 , which has two ends and is a sheet-shaped light guide plate 10, which extends to both sides into a pair of wedge shapes 101 and 102 in side view, and a groove 103 is provided at about the middle of the light guide plate 10; The light-emitting cold-cathode tube 201 is formed, and it is designed in the groove 103 at the middle section of the light guide plate 10, so that the light source of the light-emitting cold-cathode tube 20 will be thrown in from both sides of the groove 103, so it can be guided in the same size. Under the condition of the light plate, shorten the distance from the projection light source of the illuminant from one side of the light guide plate to the other side of the straight line, please refer to Figure 5, und...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap