Organic electroluminescent element

An electroluminescence component, organic technology, applied in the direction of electrical components, electroluminescence light source, electric light source, etc., can solve the problem of thin and short device design, difficult to withstand the impact of external force, display crosstalk and other problems, to achieve the suppression of black spots Generate and strengthen the effect of light, thin and short, and strengthen the impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

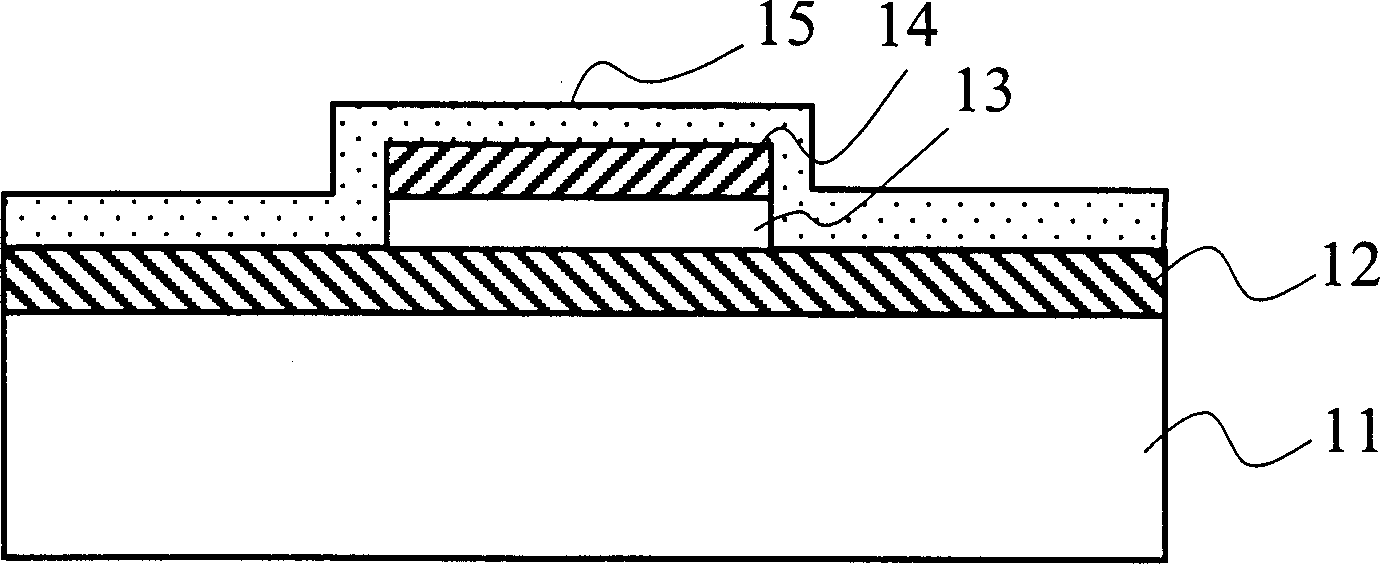

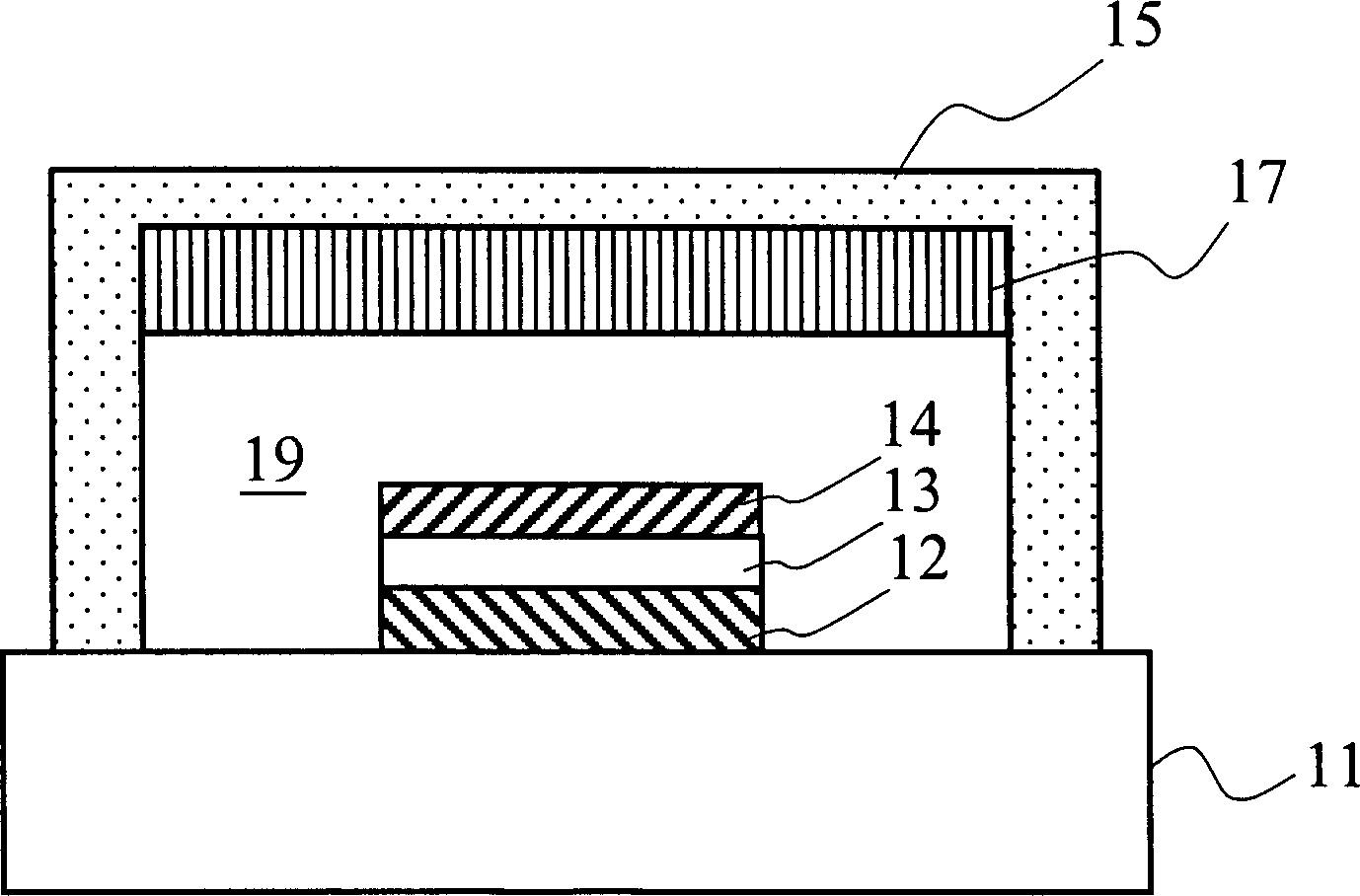

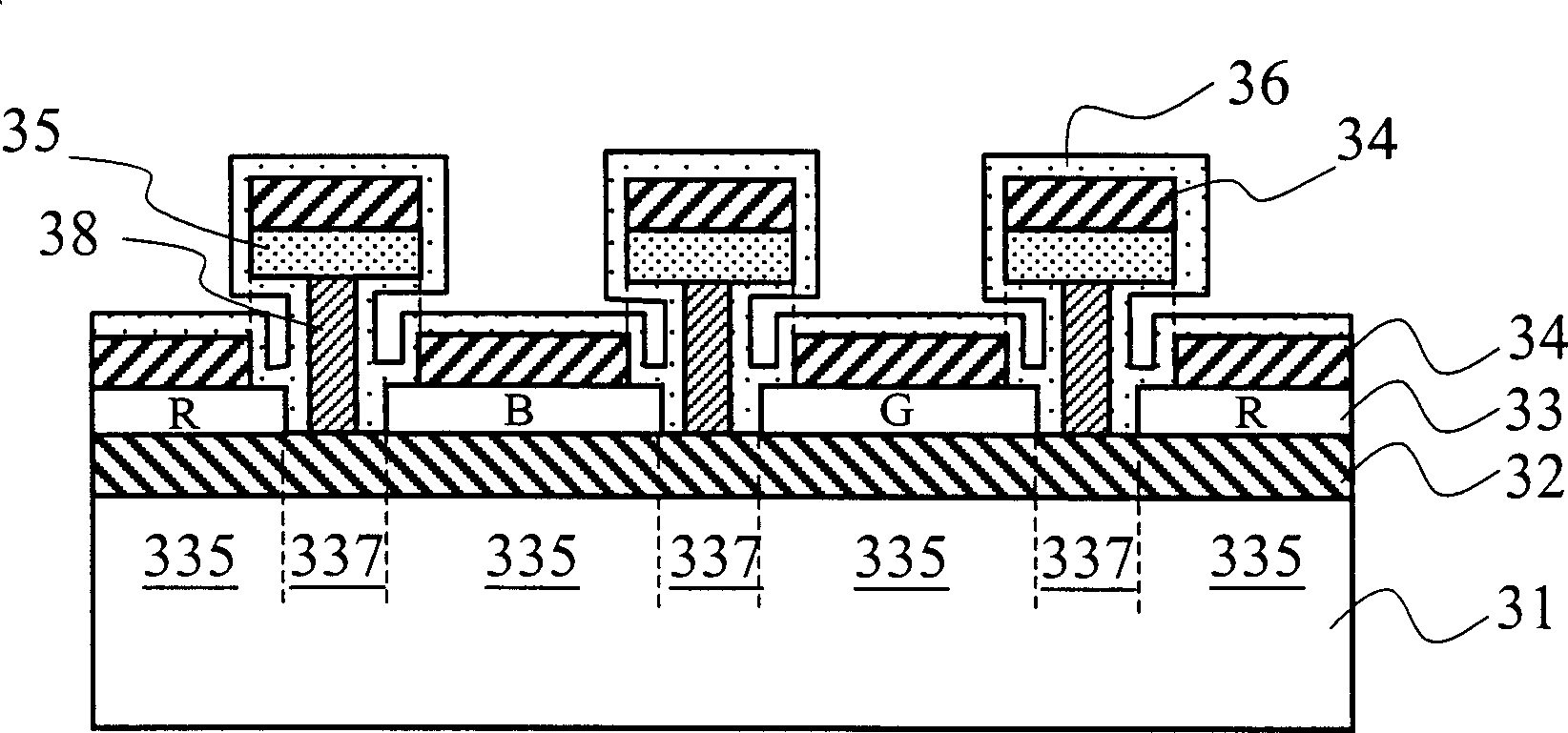

[0057] First, see image 3 , is a cross-sectional view of the structure of a preferred embodiment of the present invention: as shown in the figure, firstly, a lower electrode 32 made of a transparent material (such as ITO) is formed on a substrate 31, and then a spin coat (spin coat) is used to , dipping (dipping), vapor deposition, sputtering, etching and other film forming and patterning methods form the isolation ribs 38 in a crossed state on the surface of the lower electrode 32, and are located at the vertical extension position of the isolation ribs 38 and the dry flange 35 with a cross-sectional area greater than that of the isolation rib 38, the bottom of the isolation rib 38 is a non-luminous area 337, and between the two non-luminous areas 337 is a preset luminous area 335, and then by the general conventional On the surface of the lower electrode 32 of the predetermined light-emitting region 335, an organic layer 33 including at least one organic emitting layer (org...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com