Control method and system for weft braking mechanism capable of regulating mechanical tension of yarn in loom automatically

A technology of braking equipment and automatic adjustment, which is applied to textiles, papermaking, textiles, looms, etc., can solve the problems that the yarn tension cannot be accurately controlled and the normal operation of the textile process can be achieved, and the process can be fully stable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

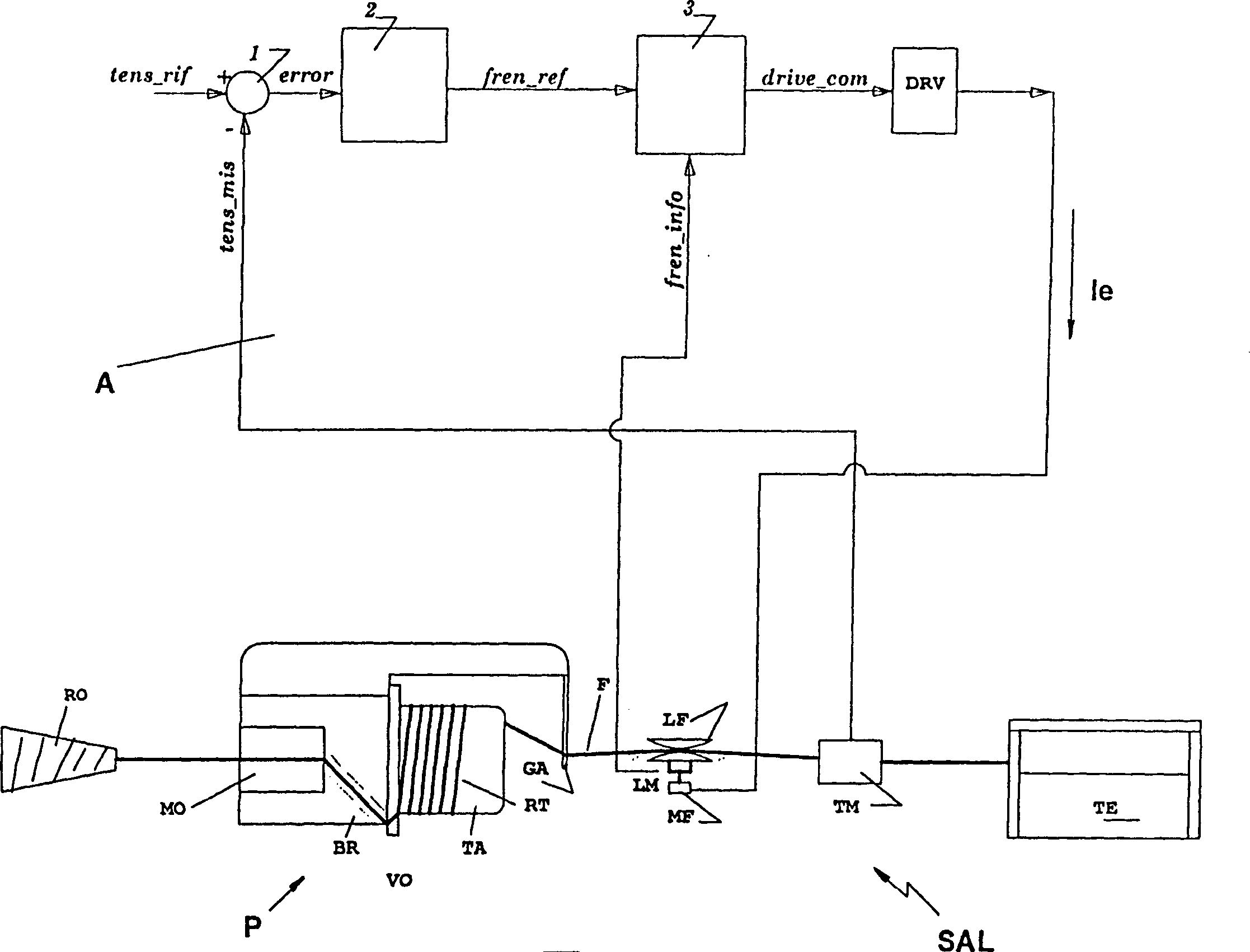

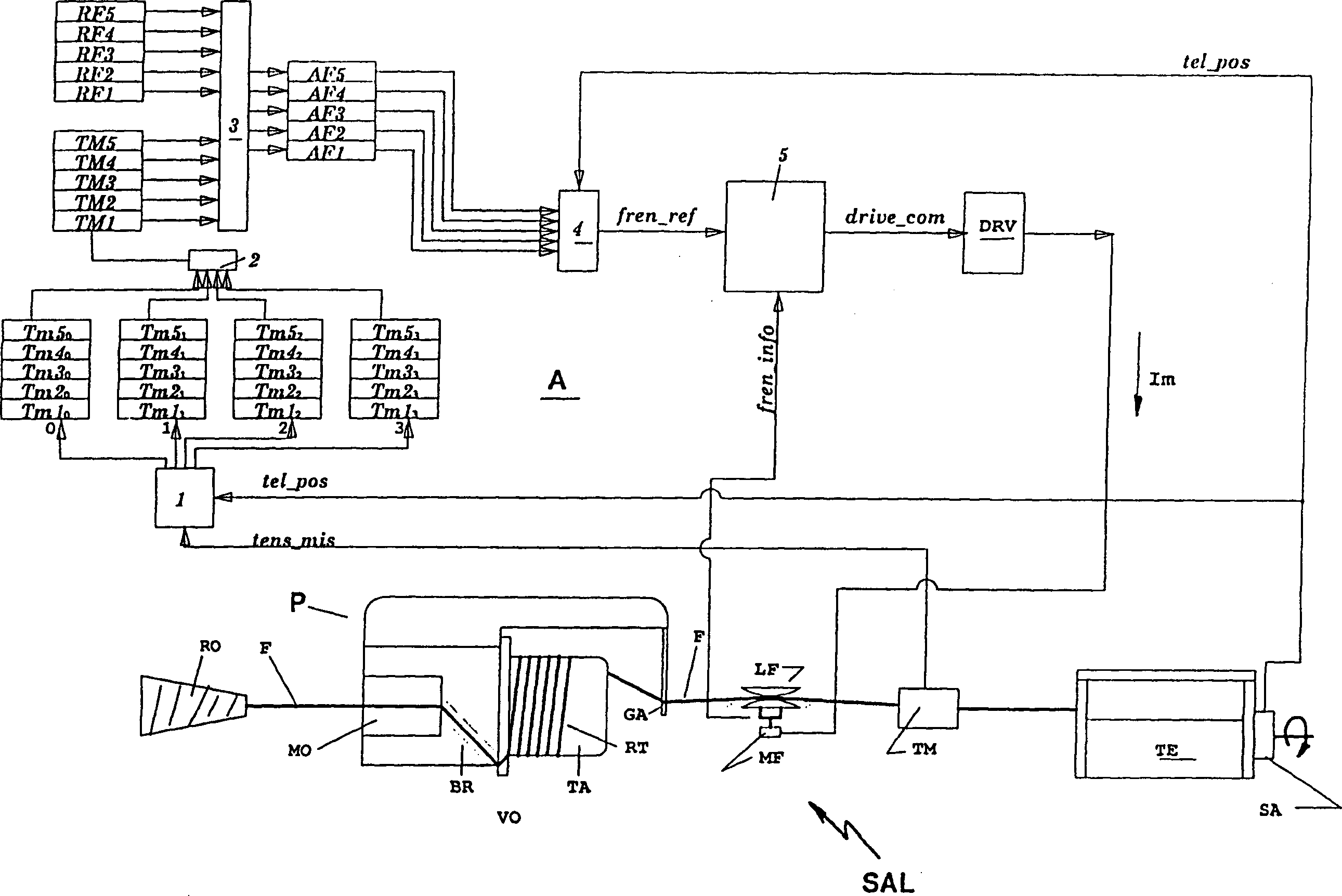

[0025] Referring to Figure 1, SAL is a known system for supplying weft yarn F to a mechanical pick loom TE. The system consists of a reel R0 on which the weft F is wound, a weft supply device P, a weft brake LF placed between the feeder P and the loom TE, for example of the type described in EP622.485 with overlapping plates , and a sensor TM that directly measures the mechanical tension T of the yarn F; said sensor is placed downstream of the brake LF. Known per se, the feeder P comprises a cylinder TA on which a rotary arm BR operated by a motor MO winds and recovers a plurality of yarn coils forming a weft yarn reserve RT. As required by the loom TE, the weft yarn is released from the cylinder TA and passed through the yarn guide GA each time the weft yarn is introduced into the yarn loop.

[0026] Similarly, known per se, the yarn brake LF comprises a fixed plate and a movable plate, between which the yarn and the motor actuator MF are passed. The latter is driven by an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com