Multiple-cavity piezoelectric film driven pump

A film-driven, cavity-pressure technology, applied in pumps, machines/engines, pumps with flexible working elements, etc., can solve problems such as large output pulsation, reduced work reliability, unfavorable flow and precise control of pressure, etc., to reduce Effect of output pulsation and flow rate increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The structure of the present invention will be further described in detail in the following embodiments given in conjunction with the accompanying drawings.

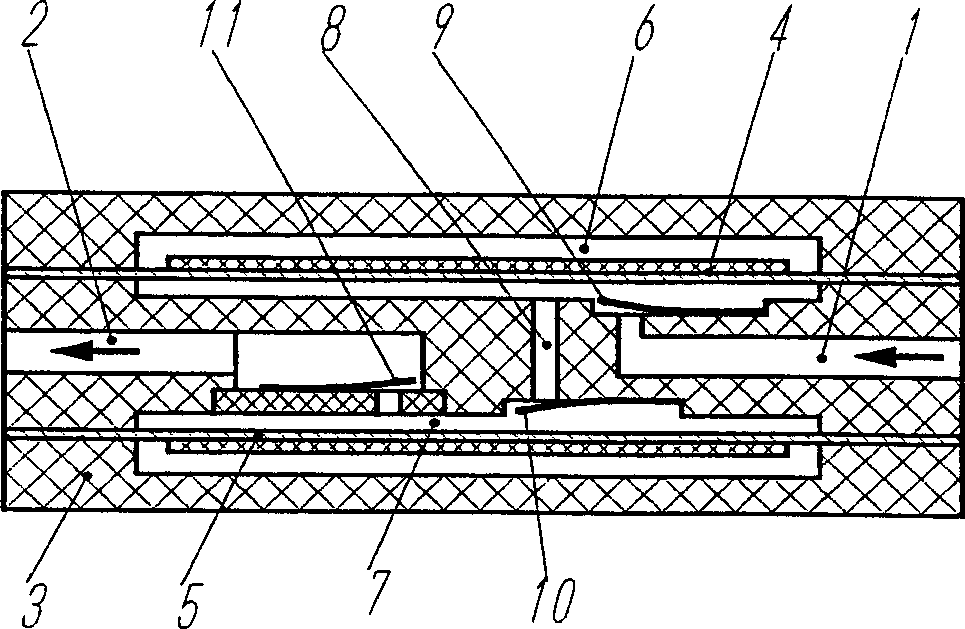

[0018] refer to figure 1 , the piezoelectric vibrator 4, 5 separates the inner cavity of the pump body 3 into closed cavities 6, 7 respectively, the fluid inlet of the cavity 6 communicates with the inlet channel 1 through the inlet valve 9, and the fluid outlet of the cavity 7 passes through the outlet The valve 11 communicates with the outlet channel 2, and the channel 8, which communicates with the cavity 6, communicates with the cavity 7 through the valve 10, and the valve 10 is not only the outlet valve of the cavity 6, but also the inlet valve of the cavity 7. This is the aforementioned Type A pump.

[0019] Its working principle is: the two ends of the piezoelectric vibrator respectively apply the AC voltage signal with a phase difference of 180°, which can ensure the pressure of the fluid to increase grad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com