Coating drum for coating apparatus

A technology of coating machine and roller, which is applied in the direction of making medicines into special physical or taking forms, etc., which can solve the problems of tablet core retention, affecting the surface quality of tablets, and wearing the surface of tablet cores, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

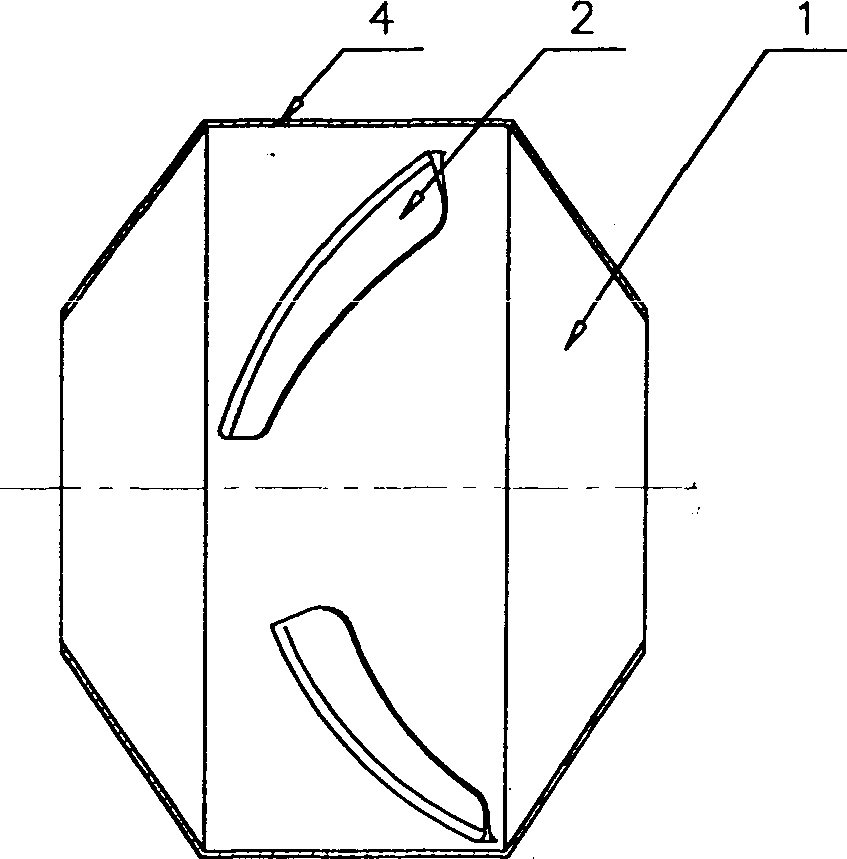

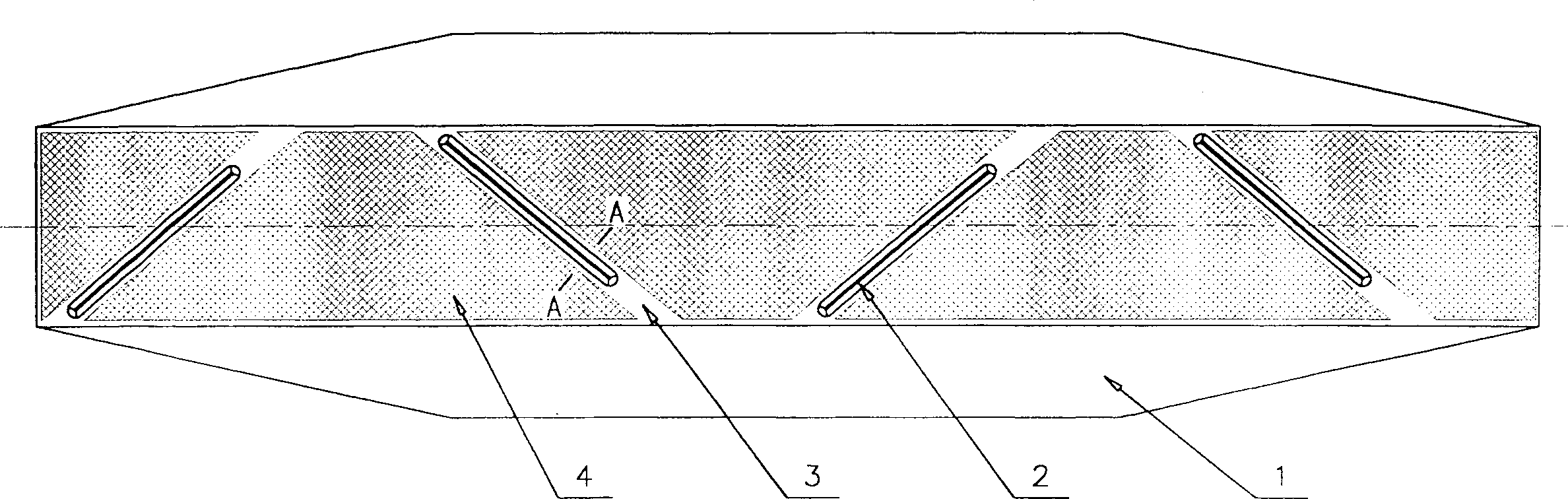

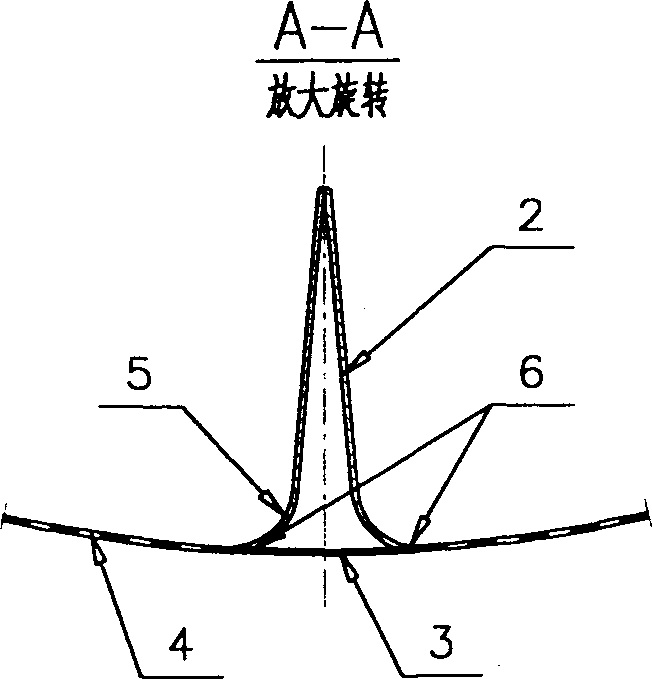

[0009] As shown in the accompanying drawings, the coating drum of this coating machine includes a drum 1 and a stirring paddle 2. The paddle paddle 2 is welded on the inner wall of the drum 1. 6 is a welding point in the figure. The bottom of the padding paddle is arc-shaped, at least when the drum rotates. The bottom 5 on one side of the direction is arc-shaped. In this embodiment, both sides of the bottom of the stirring blade are arc-shaped, so that the shape of the stirring blade is smoother and easier to clean. The joint surface 3 between the inner wall of the drum 4 and the stirring paddle 2 has no mesh, which is convenient for the paddle to be welded on the inner wall of the drum. The rest of the inner wall of the drum can have no mesh or have mesh, depending on the requirements of the coating drum, the present embodiment is the mesh surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com