Gray tone mask defect detecting method and device, and optical mask defect detecting method and device

A technology for defect inspection and gray-tone masking, which is applied in the direction of measuring devices, optical testing of defects/defects, optics, etc., and can solve problems such as non-detection and high detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

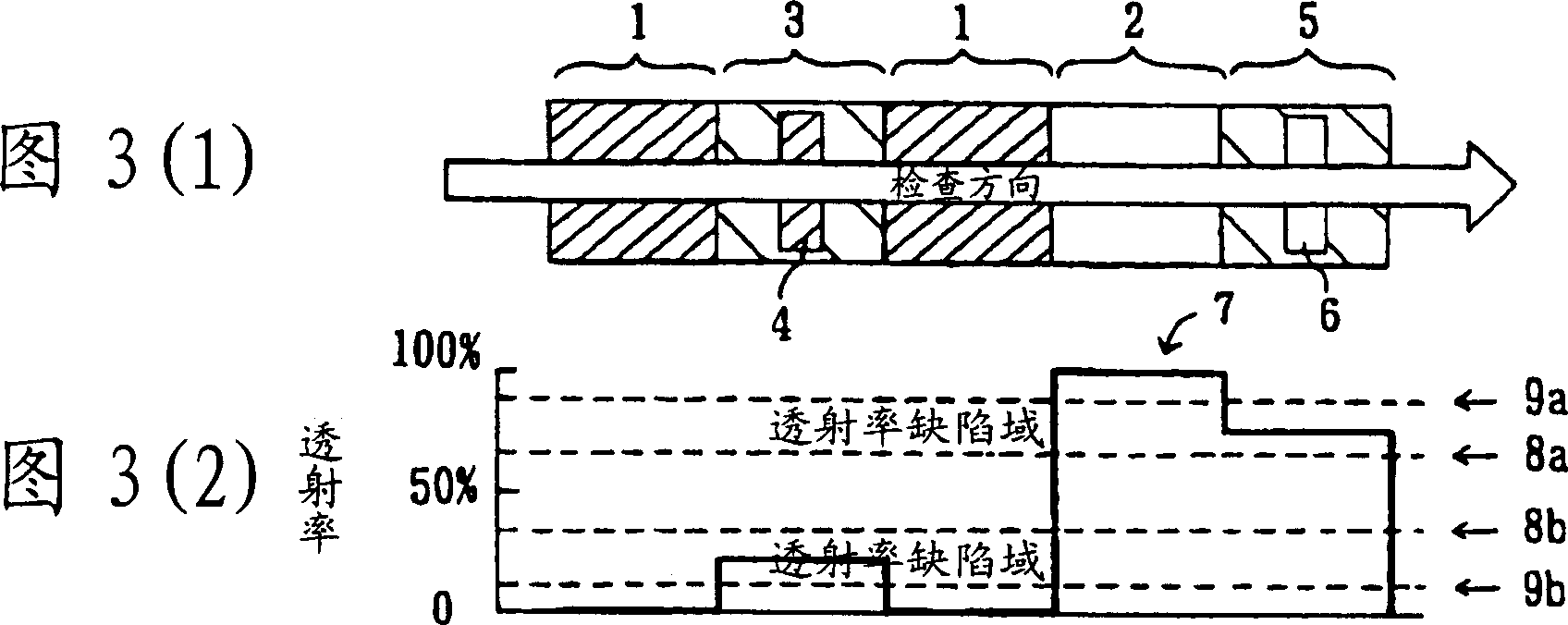

[0060] Hereinafter, the defect inspection method and defect detection apparatus of the gray-tone mask with the gray-tone portion will be specifically explained.

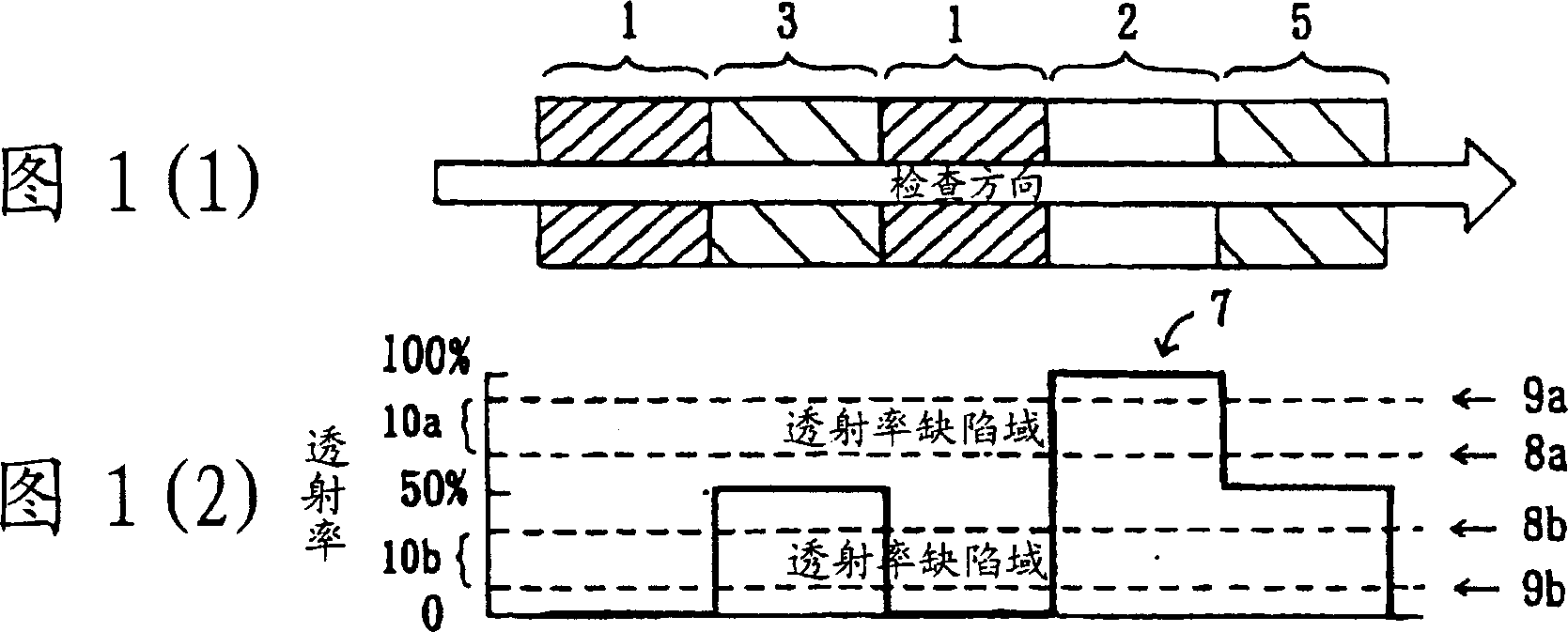

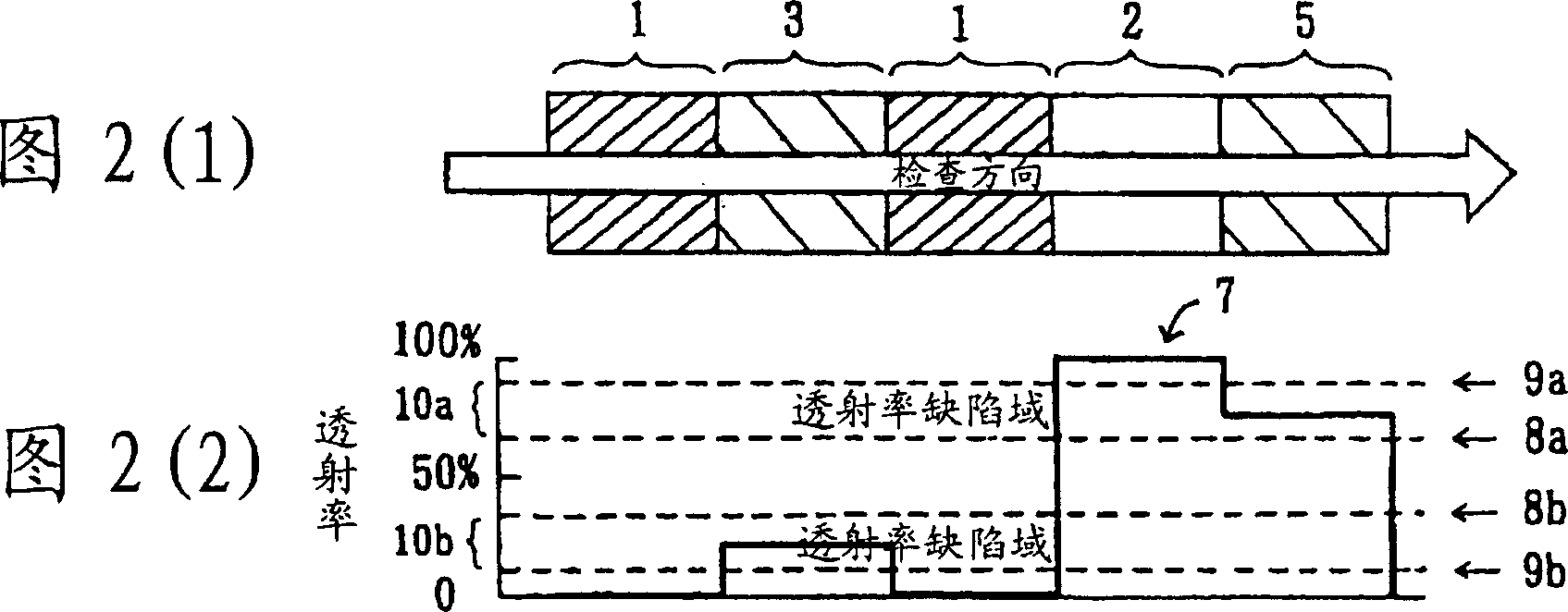

[0061] Fig. 1 (1) shows a case where no defect occurs in the light shielding portion 1, the transmissive portion 2, and the gray tone portions 3, 5. The arrow indicates the scanning direction (inspection direction) of the lens of the inspection device.

[0062] Fig. 1(2) shows the transmittance signal 7 obtained along the aforementioned scanning direction. The transmittance signal has a transmittance of 0% in the light shielding portion 1, a transmittance of 100% in the transmissive portion 2, and a transmittance of 50% in the gray tone portions 3 and 5.

[0063] The present invention is characterized in that a certain threshold is set for the above-mentioned transmittance signal to detect transmittance defects.

[0064] Specifically, as shown in Figure 1 (2), a threshold value for transmittance defects (8a on the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com