Vertical slag-cooling machine

A slag cooler, vertical technology, applied in the supporting application field of fluidized fluidized coal-fired furnace, can solve the problems of high cost, large energy required, complex movement structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

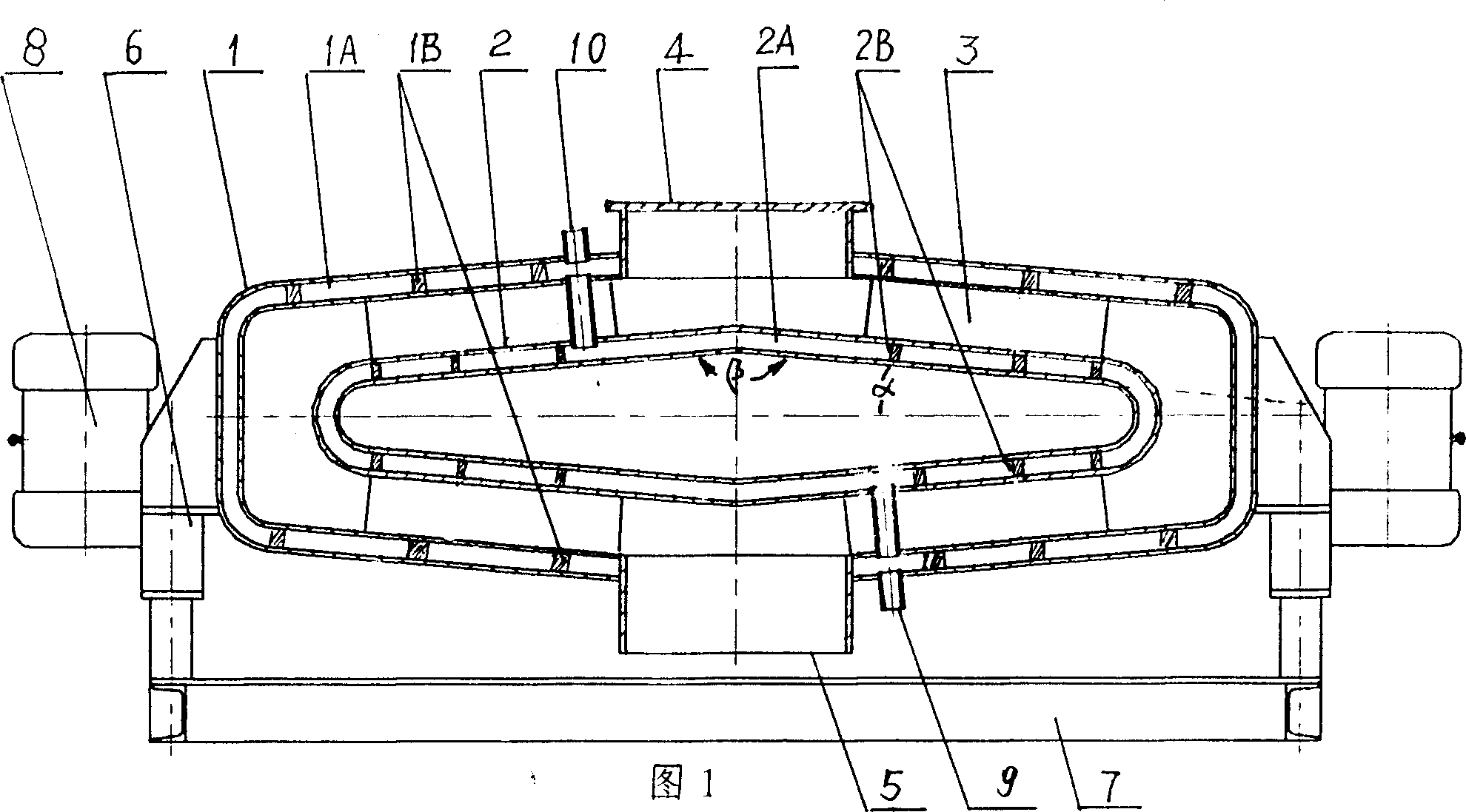

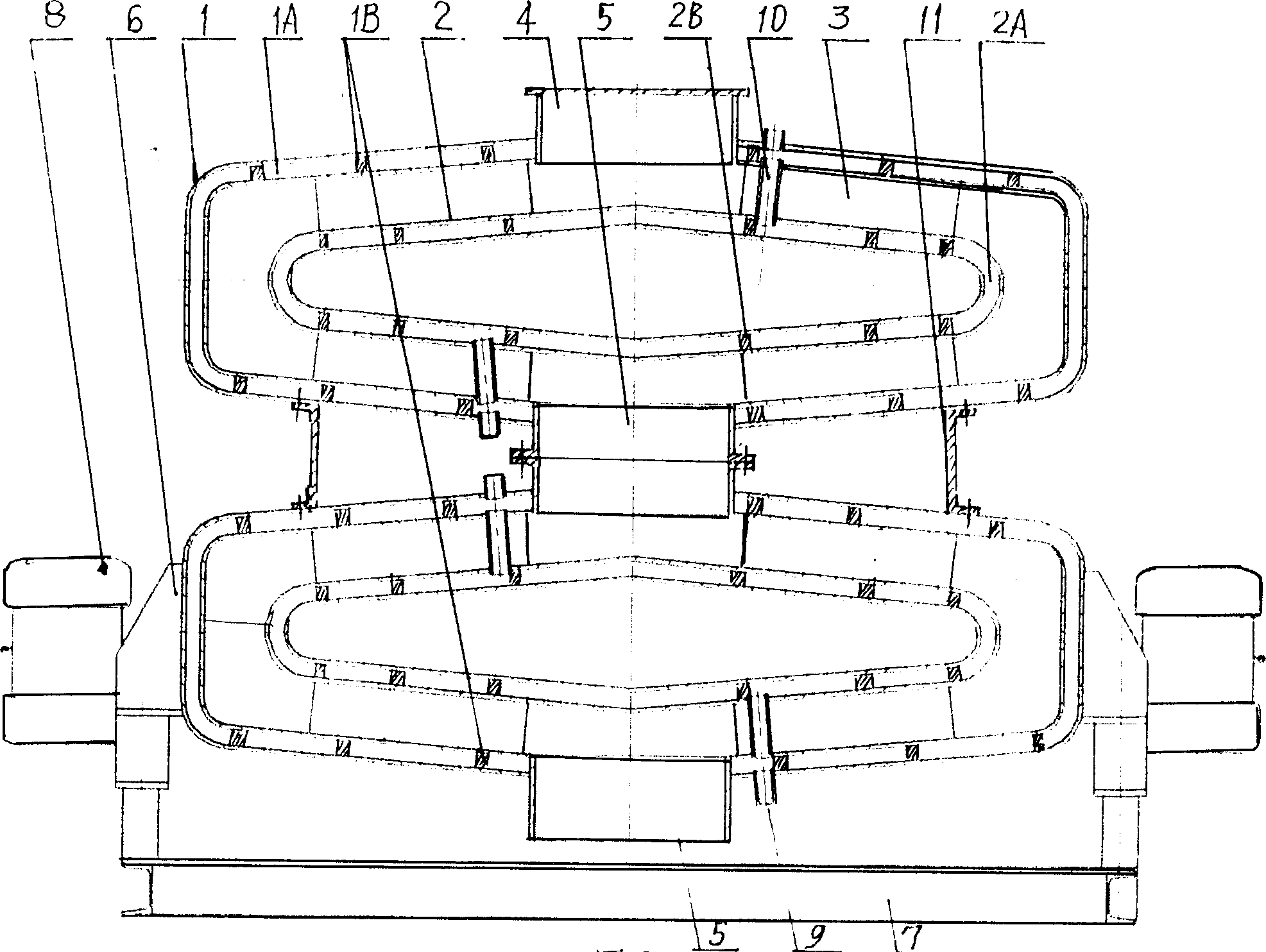

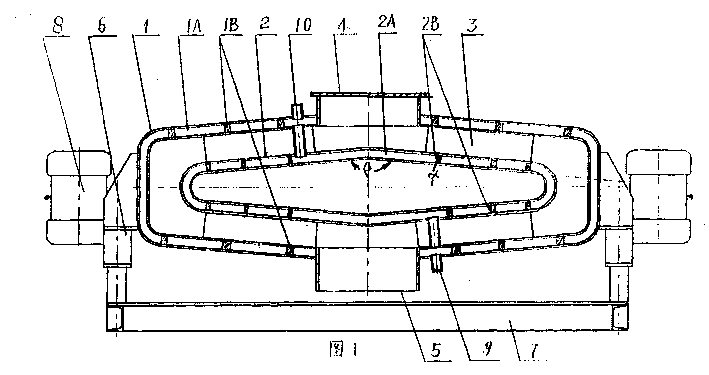

[0009] The accompanying drawings show the basic structure (Fig. 1) and series structure (Fig. figure 2 ) Two kinds of embodiments. In order to ensure the structural specification of the sandwich shell, strong resistance to deformation, and stability during operation, evenly distributed support and positioning ribs (1B, 2B) are arranged in the sandwich shell of the inner and outer boxes. The existence of these ribs makes the inner and outer shells form a whole, which not only has greater rigidity and strength, but also ensures the normal flow of circulating water in the water chamber.

[0010] The positioning support ribs 3 set up between the inner and outer boxes (1, 2) are not only for the positioning and supporting relationship between the inner and outer boxes, but also are heat-absorbing and hot slag guide plates. Therefore, its number, location, and shape have a great relationship with the working quality of the slag cooler. The simplest is the rectangular planar struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com