Method for sorting weak magnetic minerals and apparatus

A weak magnetic and mineral technology, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problems of unsatisfactory sorting effect and poor dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

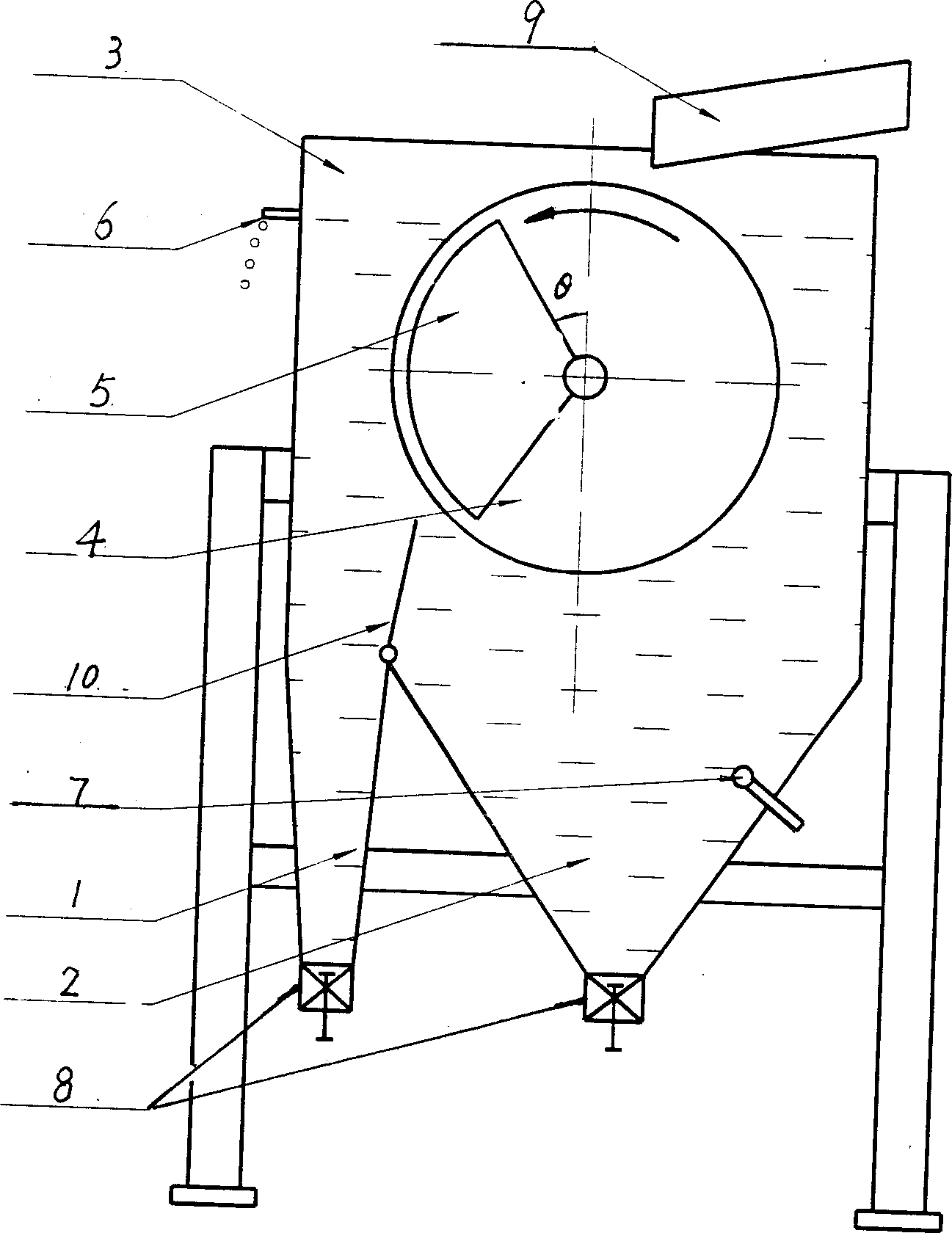

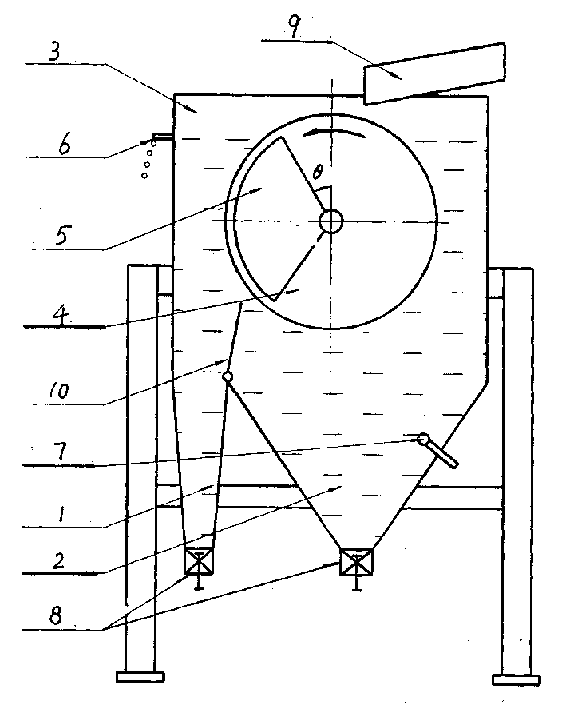

[0020] refer to figure 1 It can be seen that water has been injected into the sorting box 3, and the water level is at the highest position in the magnetic field sorting area. Then rotate the cylinder 4, so that the material is evenly fed to the cylinder 4 in the water-filled sorting box 3 from the feed hopper 9, and the above water level is always maintained during normal work, so that the fine particle materials that stick together are subjected to the action of water And fully dispersed. At the same time, under the action of gravity and buoyancy of water, the non-magnetic minerals will settle down towards the direction away from the cylinder 4, and the magnetic minerals will deflect towards the direction of the cylinder 4 under the action of the magnetic force. Separate them so that they flow from the tailings hopper 1 and the concentrate hopper 2 to complete the separation of -6mm weak magnetic minerals with high efficiency and high quality.

[0021] Based on above-menti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com