Flyash electrostatic decarbonization method and device

A fly ash and decarbonization technology, applied in electrostatic effect separation, chemical instruments and methods, solid separation, etc., can solve water pollution and other problems, and achieve significant effects of alleviating contradictions, environmental benefits and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

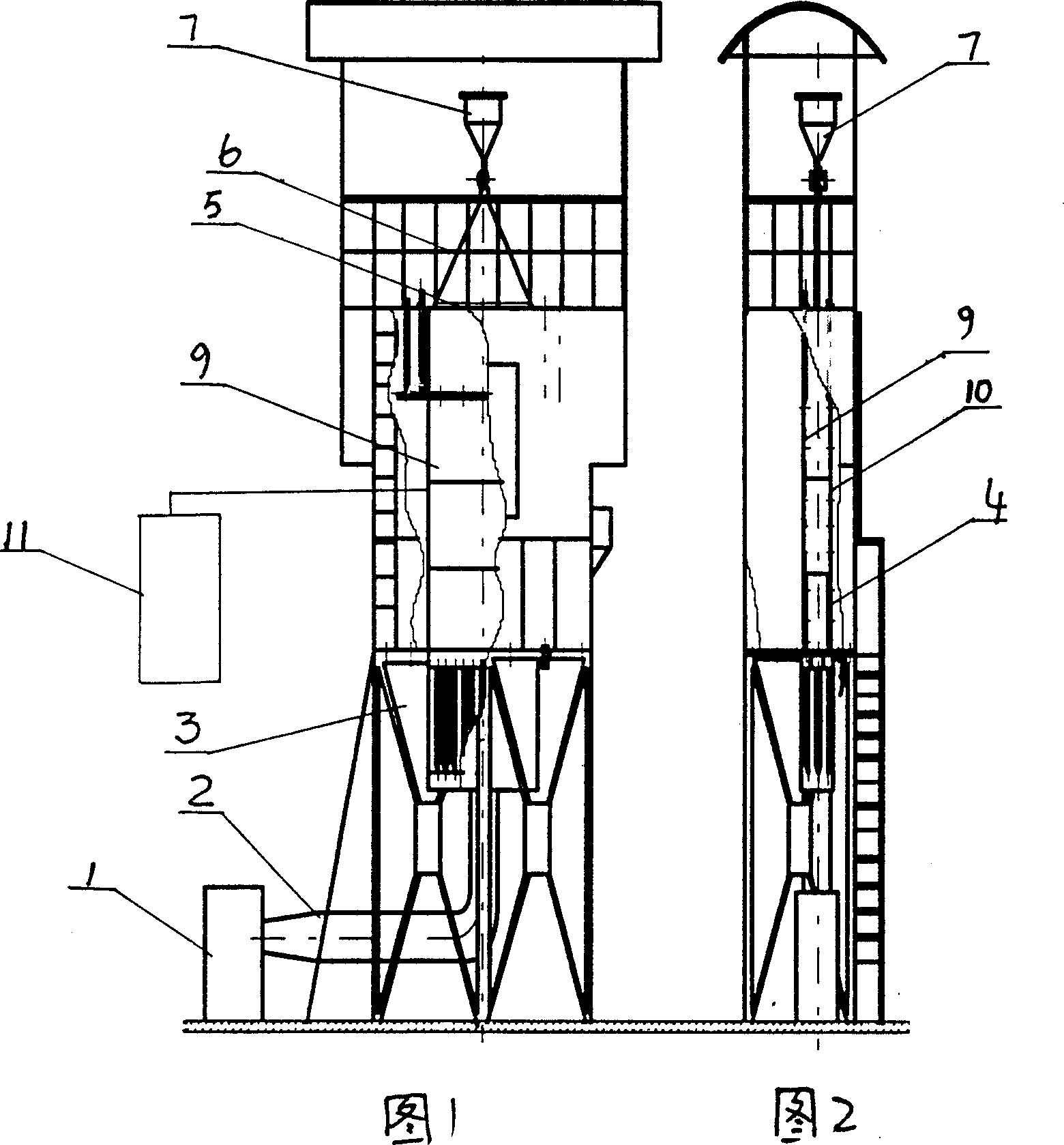

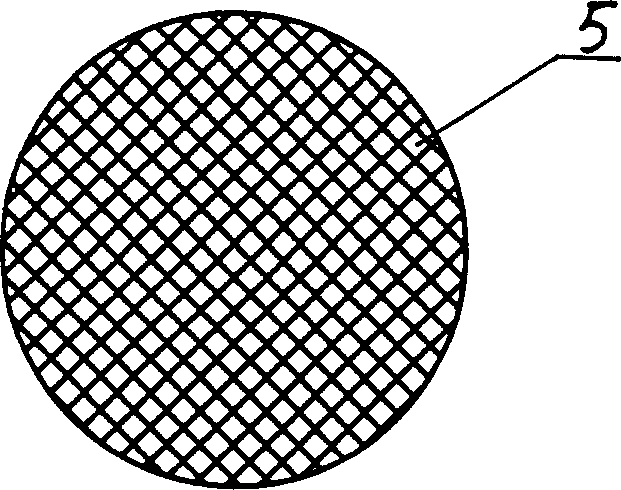

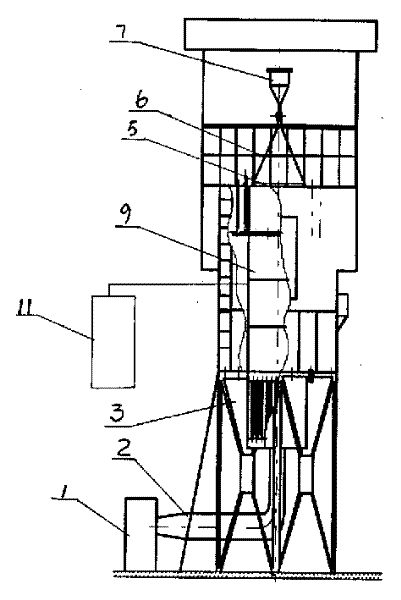

[0096] The structure of the utility model is shown in Figure 1, Figure 2 and image 3 As shown, from top to bottom, it includes a feeder 7, a disperser 6, a collection box 3, a wind pipe 2 and a fan 1. The air outlet at the lower end of the disperser 6 is covered with copper or iron or steel materials. The net-shaped friction charger 5, between the net-shaped friction charger 5 and the collection box 3, is equipped with a high-voltage negative electrostatic separator composed of two longitudinally parallel anode and cathode plates 9, 10 and a high-voltage power supply device 11 The upper ends are respectively equipped with insulating plates 4 made of epoxy resin. The distance between the cathode and anode plates 9, 10 is 30-45cm, the best distance is 35cm, and the voltage on the cathode plate is 60-100kv.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com