Automobile gas exhausting manifold branch

A technology for automobile exhaust and exhaust manifold, applied in the direction of exhaust device, air quality improvement, noise reduction device, etc., which can solve the problem of heavy weight of exhaust manifold 20, difficulty in manufacturing, shortening the overall life of exhaust manifold 20, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

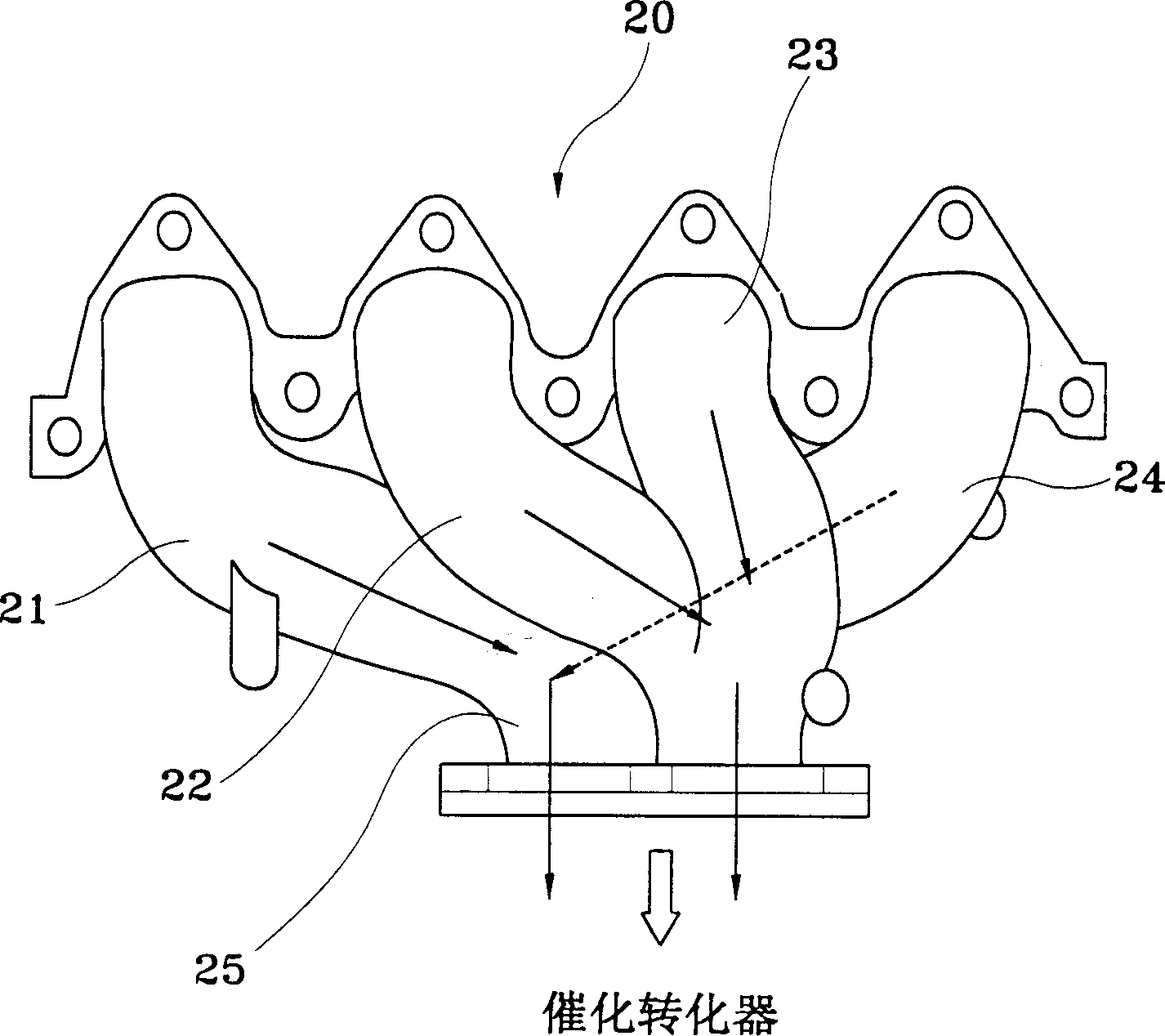

[0024] Such as Figure 5 to Figure 7 As shown, in an exhaust manifold 30 according to the present invention, the first, second, third and fourth air passages 31, 32, 33 and 34 are connected to the exhaust converging portion 35 at constant intervals.

[0025] The first air passage 31 and the fourth air passage 34 are respectively connected to both sides of the exhaust confluence part 35 at the same inclination angle. The second air passage 32 and the third air passage 33 located between the first and fourth air passages 31 and 34 are integrated in a “Y” shape, and then the combined body is connected to the exhaust confluence part 35 .

[0026] The cross-sectional areas of the first, second, third and fourth air passages 31, 32, 33 and 34 are constant throughout their length, but these air passages are connected to the exhaust confluence part, and their The cross-sectional area is expanded to a predetermined size.

[0027] see Figure 5 to Figure 7 , wherein the letter M repr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com