Biological pourpoint depression and nano concentration process for extracting aloe juice

A kind of aloe vera juice and biological technology, which is applied in the direction of emulsion delivery, medical preparations containing active ingredients, unknown raw materials, etc., and can solve problems such as high energy consumption, volatilization, and component decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

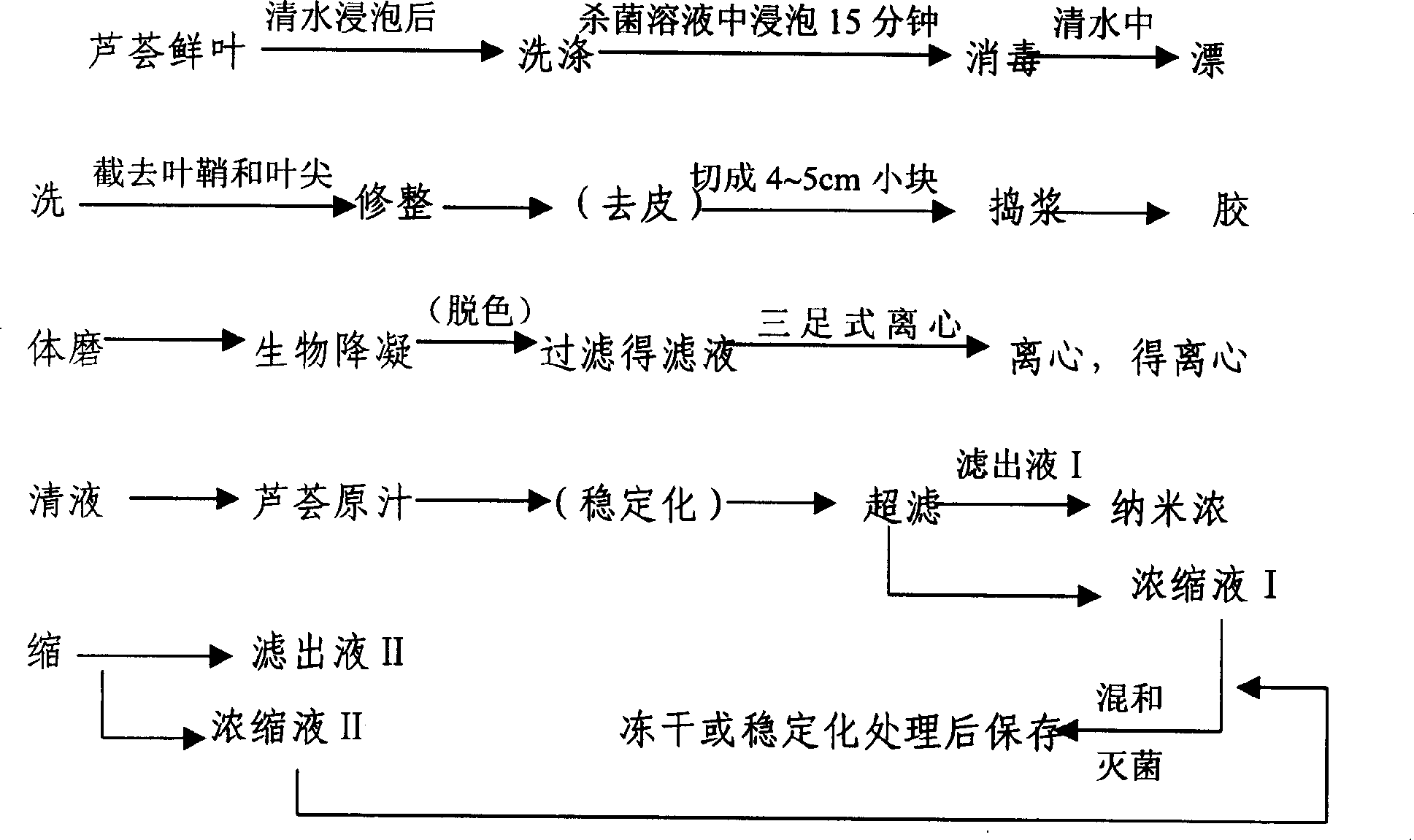

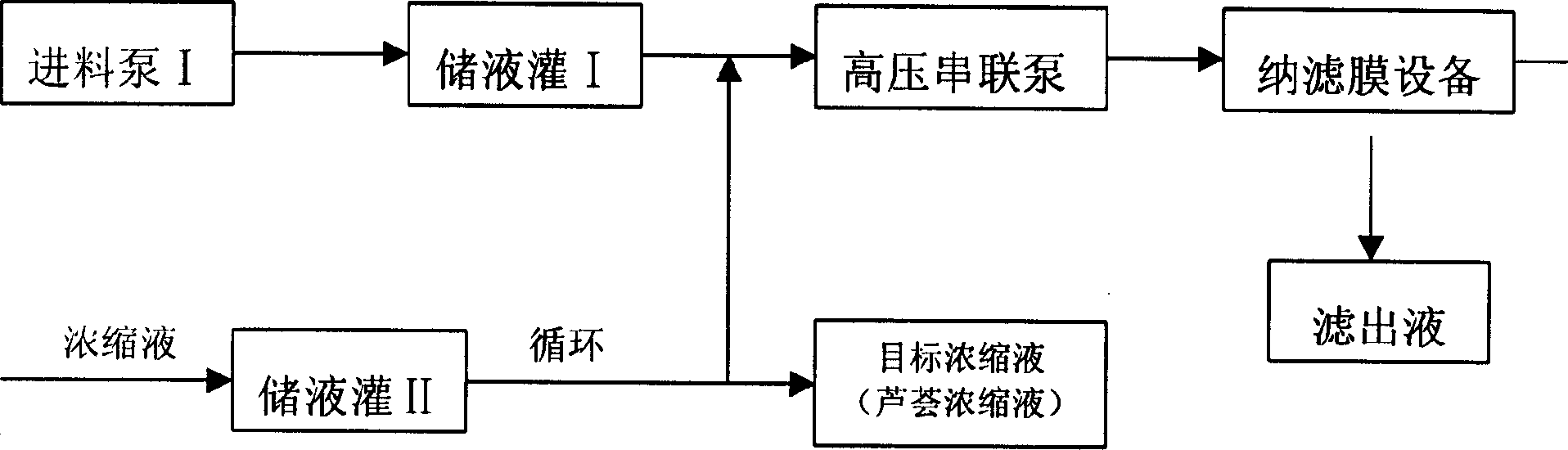

[0010] As shown in the attached drawings, after picking the fresh aloe leaves, soak them in clean water for a period of time and wash them. Sterilize by soaking in sterilizing solution for 15 minutes, rinsing with clean water, cutting off the leaf sheath and leaf tip, trimming, peeling off the epidermis, cutting the mesophyll into 4-5cm pieces, mashing, and grinding into a colloid. Then biological depressing and decoloring, add 70-120 grams of pectinase per 1000 liters of the ground aloe vera leaf juice, keep it in a stainless steel buffer tank at 45-50℃ for 25-35 minutes, and cool it to room temperature naturally. The viscous aloe vera leaf juice becomes clear and translucent. The aloe vera leaf juice after biological decoagulation is filtered, the filtrate is centrifuged through a three-foot centrifuge to obtain the centrifuged supernatant, and the centrifuged supernatant is circulated and filtered through the ultrafiltration membrane to obtain the concentrated juice I and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com